Well-known technology and development partner to global and Indian OEMs, MAHLE, displayed its extensive product range covering engine systems, filtration, thermal management and mechatronics for both conventional and electrified vehicles at the IAA Commercial Vehicle 2018 at Hannover.

The company’s pavilion hosted technologies for modern, low-emission combustion engines, hybrid drives, and fuel cell-powered vehicles in an attractive crystal display of trucks. Addressing the press, Dr. Jörg Stratmann, CEO of the MAHLE Group, said: “We are shaping and accompanying the breakthrough in the commercial vehicle market with solutions that are ready for series production. Independently of the drive type, we always focus on a holistic systems approach. Vehicle components can only run efficiently and reliably throughout the entire service life of a commercial vehicle and tap the full technical potential if they work together perfectly.”

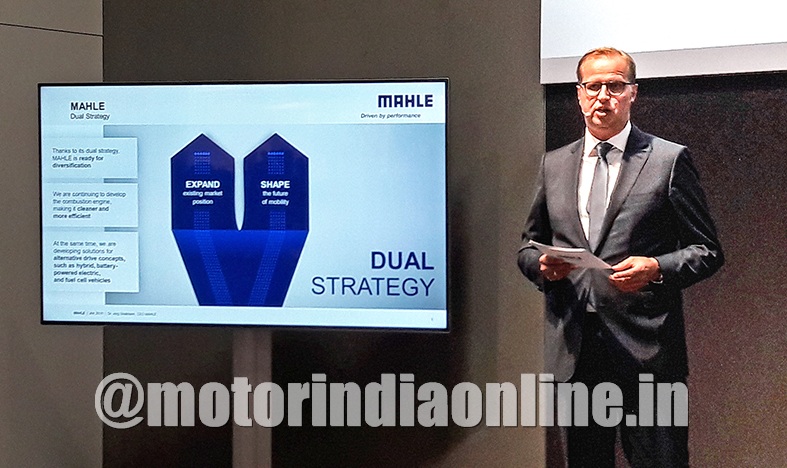

Mr. Arnd Franz, Member of the Management Board, Sales, Application Engineering and Aftermarket, noted that the IAA 2018 is a big step forward from the previous editions as it moves further towards electromobility and hybridization. As he mentioned to us during this year’s Auto Expo about MAHLE’s dual strategy, Mr. Franz reiterated that MAHLE will continue to provide technological support in the areas of IC engines as well as emerging technologies like electromobility. “We continue to push forward on more efficiency on the combustion engine technology including waste heat recovery for CO2 savings and full speed for electrification for hybrid trucks and components, modules and systems for the fuel cell technology that may be a game changer for long haul and heavy-duty industry.”

Mr. Raj Kalra, President, MAHLE India, emphasized on MAHLE’s twin track approach and stated exclusively to MOTORINDIA: “The advantage of adopting the dual strategy is that we are able to focus on countries that are rapidly moving from traditional engines to electric, without losing sight of countries like India, where there is still a foreseeable future of IC engines for the next decade and more.”

“As our CEO, very famously, has said that the very last piston that will be installed in the very last IC engine will be a piston from MAHLE. This very well describes our intention.” he added.

Impetus on Innovation

MAHLE continues to invest and develop new technology towards improving the efficiency of the internal combustion engines, to reduce the carbon footprint as much as it can. “That’s the theme of the show for us. ”

“We start from the improvements on the IC engine side, move to the middle ground that is hybrid and then show our innovation on the electrification side. That is what we are committed towards and hence showing our innovation in all these three fields. We are already working on Bharat Stage (BS) VI for India and on innovations related to IC engines like the new kind of piston range that are more efficient – going forward, we are keen to offer steel pistons in India; steel is denser than aluminum but three times stronger, leading to a piston that is more resilient to higher pressures and temperatures with no increase in weight”, explained Mr. Kalra.

He continued: “New product offerings such as hollow and assembled camshafts, plastic cylinder head-cover or oil pans, facilitate significant weight reduction from the incumbent products and improve fuel economy. We are working on special coatings for piston rings which will reduce the friction and improve the efficiency of the engine. Keeping in mind India’s hot climate, we can offer market-specific concepts to address the challenges of dust-laden countries, extreme conditions of use, or increased exposure to water.”

“MAHLE strives to provide car users and their families with an odorless and dustless cabin environment; not only that, but an interface on the dashboard to monitor the cabin air quality and level of dust in your vehicle.”

To keep the best foot forward in the field of mechatronics, MAHLE has acquired three companies to provide e-mobility solutions.

One is Letrika, based in Slovenia, develops and manufactures innovative electric motors, starter motors, generators, and electrical drive systems for customers in the passenger and commercial vehicle, agricultural and construction machinery market along with other industrial applications. Then there is Japan-based, Kokusan Denki Co. Ltd., develops and manufactures electric DC motors for ABS and ESC (Electronic Stability Control) units, as well as BLDC (brushless DC) motors for steering assistance, along with ignition components, alternators, and fuel injection systems for small engines, which are essentially used in motorcycles, small commercial vehicles, and recreational vehicles. Recently MAHLE acquired a Spanish company called Nagares S.A., which will focus on power electronics, like controllers, DC-DC converter, on-board chargers and sensors.

“The acquisition of these three companies will help us gain expertise as well as provide cost-efficient solutions in the areas of electric motors, electric drive systems, inverters, on board chargers, sensors, etc.,” he informed.

Gearing for alternative eco-system

Even when the company works on developing solutions from conventional IC engines to electric, there are alternate business in the same eco-system that might not change drastically, but require a few innovations. Take for example thermal management. “Doesn’t matter if you are using LNG, CNG, Electric or anything else you will still need to cool your cabin. Instead of cooling the engine one will still need to cool the battery pack when the world moves to electric. In hot temperatures it will need to be cooled and in extreme cold temperature it will need to be heated. We are already moving in the direction and providing thermal management solutions to our customer base, for all propulsion type vehicles, he stated.

Captive R&D and Engineering Center

It is evident that MAHLE, wants to make products that are environment-friendly, lowering carbon emission, improving engine efficiency as well as providing comfortable ride with their filters and thermal management system; thus taking care of the external atmosphere as well as car’s internal cabin environment. Such wide range of work across different products also calls out for extensive investment in research and development (R&D).

“We are in the process of developing a full MAHLE R&D and engineering center in Pune which will have over 500 engineers working on Indian as well as global projects. This shows long term commitment of MAHLE towards India as this engineering center will become one of the integrated R&D centers of MAHLE globally, sharing knowledge and expertise amongst other centers of the MAHLE Group for all product lines,” concluded the company President.