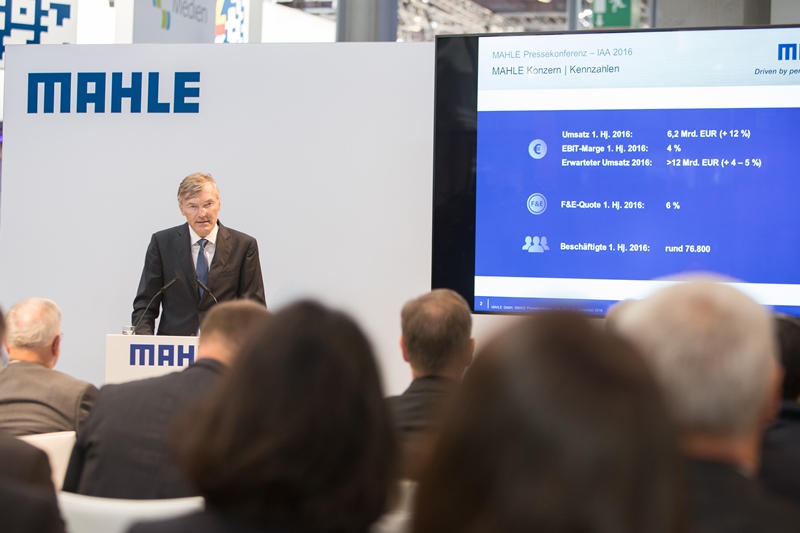

With regard to the sales figures of the first half-year, it should be noted that the most recent acquisitions were consolidated for the first time in this period. Excluding the acquisitions, MAHLE grew by 3.8 percent in the first half of the year and thus faster than the global vehicle market. During the same period, the production of passenger cars and light commercial vehicles rose by 2.4 percent, and medium- and heavy-duty commercial vehicles by 1.3 percent. “We expect an increase in sales of at least 4 to 5 percent for the year as a whole,” explained Wolf-Henning Scheider, Chairman of the MAHLE Management Board and CEO, during the press conference at the IAA Commercial Vehicles. Consequently, MAHLE will achieve sales of more than EUR 12 billion for the very first time in 2016. As at June 30, the MAHLE Group had a total headcount of around 76,800 employees, 1.6 percent more than at the turn of the year.

“As already announced at our press conference on the Financial Statements in spring, the integration of the new divisions is connected with additional expenditure that initially impacts our result. Moreover, the recently acquired units have not yet reached the earning capacity of the existing MAHLE divisions,” asserted Scheider.

“Internally, however, we can already see evidence of the additional knowledge and expertise gained in key areas and that our innovative strength has been solidified. This applies particularly to the fields of electric drives and thermal management,” said Scheider. Compared with the same period of the previous year, MAHLE has further expanded the investments in research and development. The research and development ratio rose from 5.6 percent to 6 percent in the first half-year. In the same period, MAHLE registered 174 patents, which corresponds to at least one patent per working day.

Consistent pursuit of dual strategy

Mahle is systematically embracing a dual strategy. This means that, on the one hand, Mahle is working intensively on the further optimization of the combustion engine. “This technology still has a great deal of potential that we intend to exploit,” stressed Scheider. “On the other hand, we are also focusing on the development of alternative drive concepts, such as battery-based e-mobility and fuel cells,” he said. The company is not just focusing on the ongoing development of the conventional powertrain, even for commercial vehicles. Electrification will increasingly contribute to improving efficiency also in this vehicle sector. “MAHLE is already offering the necessary technologies today, such as thermal soaking systems for batteries,” remarked Scheider.

Innovations for greater efficiency, reliability, and driving comfort

Efficiency, reliability, and driver comfort: “We are driven by these three principles when it comes to commercial vehicles. We are increasingly taking a holistic systems approach as we look for new solutions. It is no longer sufficient to view and optimize individual components in isolation. The interactions with other systems in the vehicle are simply too diverse,” said Scheider. Only the interplay of all improved components and systems enables a maximum advantage in fuel consumption.

The new controllable pendulum-slider oil pump from MAHLE, for example, enhances efficiency. It enables pressure and volume flow to be generated on demand and the required power consumption to be reduced to a minimum. Depending on the control strategy, simply supplying oil to meet demand can result in fuel savings of up to 1.5 percent. MAHLE is thus setting new standards in terms of the efficiency and reliability of the oil supply in commercial vehicles.

New camshaft technology works without pressurized oil

In close collaboration with several customers, MAHLE is currently working on a camshaft technology that will replace conventional bearings with wear-free roller bearings. As these do not rely on pressurized oil, the burden on the oil circuit is reduced and complex oil channels to the bearing points are no longer required. The associated simplification of the cylinder head design will in turn open up new opportunities, such as stop-start applications in commercial vehicles.

Improved engine components, less friction, and reduced oil requirement based on actual demand, the combination of these optimizations and innovations leads to lower fuel consumption and consequently reduced CO2 emissions. For heavy-duty commercial vehicles, Mahle can achieve a reduction of around 3 percent in the future, thanks to the interplay of optimized oil management and innovative engine components.

Another innovation that MAHLE is introducing at the IAA is the first map-controlled thermostat for commercial vehicles. These thermostats have already been successfully introduced as a series production application in passenger cars. They react particularly fast and operate even at low temperatures. As a result, the thermostats are extremely flexible in any driving situation and can optimally condition the coolant. In systemic interaction with the controlled E-Visco® coolant pump and the E-Visco® fan, the map-controlled thermostat can reduce fuel consumption and therefore CO2 emissions by 2 percent.

High mileage with MAHLE components

Mahle components are not only efficient, but also reliable. They already address additional future requirements, such as low-viscosity oils or increased specific outputs. In addition, they ensure that engines, as expected for heavy freight transport, also reliably fulfill a service life of one million miles. The analysis of an engine from a heavy-duty, long-distance hauling truck demonstrates just how reliable the MAHLE components are. Although it had already been on the road for about 1.2 million kilometers, the pistons, piston rings and pins, or cylinder liners and bearings do not show any significant wear. This was achieved despite each piston having to withstand well over half a billion ignition cycles.

Efficiency and driver comfort complement each other

Systems used to ensure a good atmosphere in the driver’s cabin currently cause an increase in fuel consumption of approximately 0.2 liters per 100 kilometers. With the ECO A/C system from MAHLE, however, the increase in consumption is limited to only 0.03 liters per 100 kilometers, which corresponds to a reduction of 83 percent. This outstanding result was attained by redesigning or optimizing all components, its interaction with the overall system, and the controls of the air conditioning system. “This example clearly shows how we achieve impressive results by both addressing the various components and taking a systems approach,” explained Scheider.

At the same time, we are working with BHTC, the joint subsidiary of Mahle and Hella, to optimize the operability of the air conditioning system. The objective is to create haptic operation via a touch screen, which also responds to swipe gestures. In this way, the driver can better focus on the traffic and is therefore safer on the road. Safety is also about allowing drivers to recover during breaks. Thermal comfort plays a key role in this respect. The electrical standstill air conditioning from Mahle ensures pleasant temperatures for up to eight hours with zero emissions and in virtual silence.

![ProEXR File Description =Attributes= cameraAperture (float): 36.000000 cameraFNumber (float): 3.774344 cameraFarClip (float): 1000000015047466200000000000000.000000 cameraFarRange (float): 1000.000000 cameraFocalLength (float): 37.743443 cameraFov (float): 50.993324 cameraNearClip (float): 0.000000 cameraNearRange (float): 0.000000 cameraProjection (int): 0 cameraTargetDistance (float): 200.000000 cameraTransform (m44f) channels (chlist) compression (compression): Zip16 dataWindow (box2i): [0, 0, 4959, 3506] displayWindow (box2i): [0, 0, 4959, 3506] lineOrder (lineOrder): Increasing Y pixelAspectRatio (float): 1.000000 screenWindowCenter (v2f): [0.000000, 0.000000] screenWindowWidth (float): 1.000000 =Channels= A (half) B (half) G (half) R (half)](https://www.motorindiaonline.in/wp-content/uploads/2016/09/03_Controllable-cooling-system.jpg)