Headquartered in Lucknow, Uttar Pradesh, Motor and General Sales serves multiple industries through their work in commercial vehicle fabrication, agricare products, education, lifestyle and entertainment. Rajesh Rajgor speaks to Director Raghav Gupta to know about their latest developments and plans for growth in a competitive market

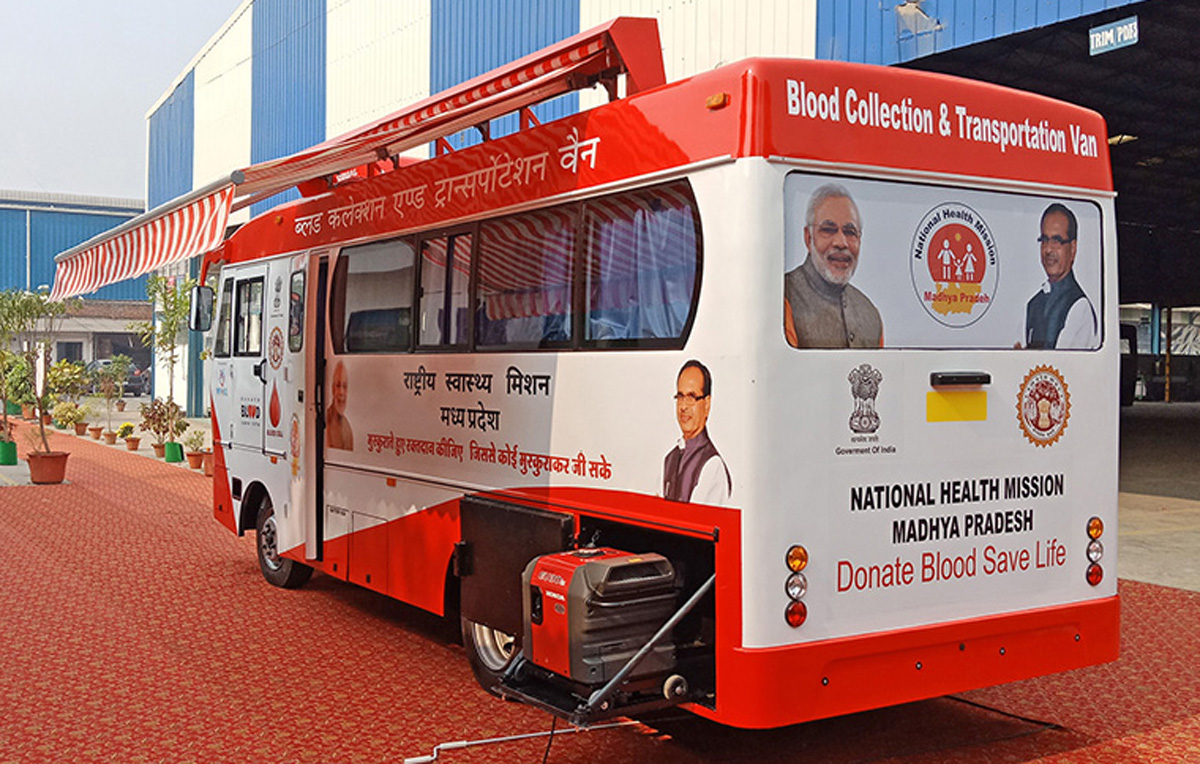

The pandemic’s spread has increased the demand for emergency vehicles such as ambulances that can provide quick medical assistance. Motor and General Sales (MGS), which is widely recognised for its fabrication of buses, load bodies, tippers and tip-trailers, and medium and heavy commercial vehicles, produced corona virus testing vans as well as mobile blood collection vans in response to the requirement. “We have been building these mobile medical units on Tata Motors 410 chassis and have given 52 vehicles to the state government,” informs Raghav Gupta, Director, MGS.

MGS, which opened the year 2022 with a whooping order of 520 mobile veterinary units, works in sync with the dealers of Tata Motors and BharatBenz in the state of Uttar Pradesh and can easily accommodate 100 units of load bodies and tip-trailers a month. “We have two manufacturing units – one that takes care of the commercial vehicle products like cargo bodies, tipping trailers, trailers and mobile units along with railway wagons and another that takes care of our agricare products. We adhere to iCAT and ARAI norms and use high-grade material that is less in weight and has a higher payload capacity,” Gupta says.

“Not just that, this is also in keeping with industry needs. Our engineers ensure that the vehicles are more stable in adverse weather situations. As a result, this assists our clients in remaining competitive in the industry. We also give a one-year body warranty on all our products,” he adds. The changing dynamics with respect to light-weighting and thrust on operational efficiency calls for manufacturing units to be prudent in their practices. MGS’ emphasis on using materials like Domex, BS 46 material and getting involved with clients right from the designing phase helps them make profitable products for customers.

“Apart from successfully building bodies and tippers to meet the requirements of customers possessing vehicles from the stables of Tata Motors, BharatBenz and other OEMs, we have served clients requirements for Apco Infratech Ltd., Chopra Traders and Society Trucking, amongst a few,” Gupta shares. The organisation has been fortifying its design and engineering set-up from time to time in order to realise its vision of being a sought-after design and engineering firm that is well-diversified across numerous requirements. “Our young and adaptable team is backed by seasoned design, manufacturing, and engineering professionals. We have an in-house research and development team as well as a team of talented and creative designers. Our two manufacturing divisions are spread across 8 acres,” he further informs.

Expanding Expertise

The ongoing pandemic has been a learning curve for individuals as well as business owners. It has taught companies to extend their reach and do maximum with resources available. “We have learned quite early in the business that even if we are not earning high margins the business turnover should flow. These dynamics have taught us to be lean in operation with manpower so that rotation should happen to sustain us during the tough times and in a competitive industry,” Gupta says. The company has undertaken projects like manufacturing refrigerated containers, load bodies for medium and heavy commercial vehicles and light commercial vehicles along with waste collection vans for Nagar Nigams. They manufacture roughly 100 units of load bodies on Tata Motors’ LCVs. In the past two years MGS has grown with their work for Indian Railways too.

“We are approved by the Research Designs and Standards Organisation (RDSO) to manufacture products for Indian Railways,” affirms Gupta. The agricare business of MGS produces world-class agricultural trolleys and implements that are manufactured utilising jigs, fixtures and dies to ensure joining accuracy, inter-changeability and premium quality-tested materials supplied from the most dependable and OEM authorised suppliers. Tipping and non-tipping trolleys, heavy-duty tillers, seed drills, rotary tillers, and rotovators are among the products available. “For agricultural implements we make products like rotavators and cultivators,” Gupta shares.

“We aim to grow from the current number of 49 MGS agricare dealers and expand pan-India,” he adds. The company sold 3,000 units of rotavators last year and the ambition is to double it in the next one year. However, given the crisis farmers faced during the pandemic, Gupta concludes, “We would be able to look at selling 4,500 units this year. Our fabrication unit will continue to serve the orders for fleet operators and dealers in need of genuine, high-quality tip-trailers, mobile medical units, ATM vans, cash vans and load bodies. We are also mulling on making bodies for e-rickshaws and electric buses.”