700-member team involved, 2,000+ components fine-tuned

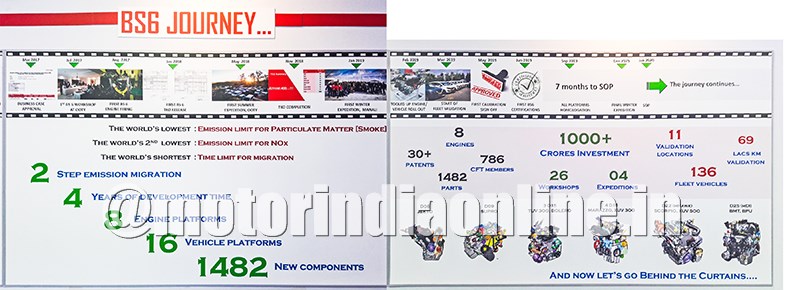

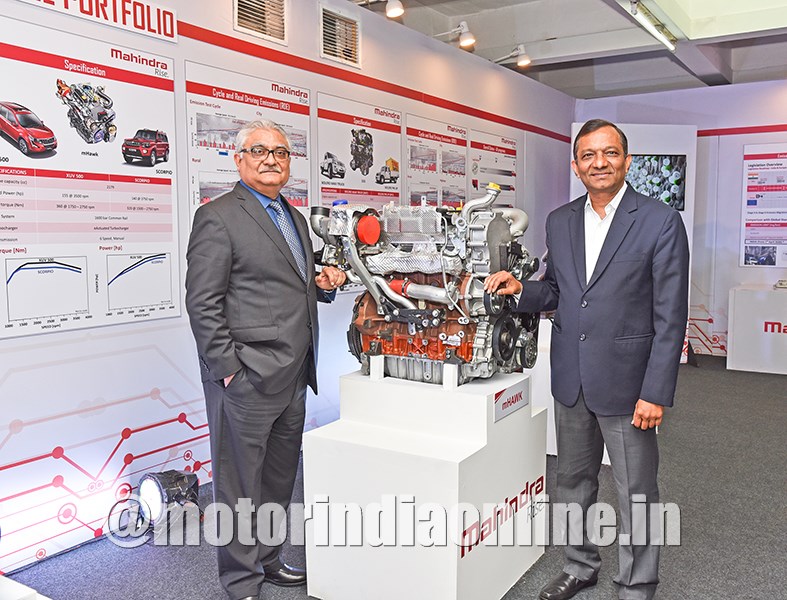

In its efforts to meet the upcoming BS-VI emission norms, Mahindra and Mahindra (M&M) has invested Rs. 1,000 crores plus for the transition from BS-IV to BS-VI. At a knowledge-sharing session, termed ‘Demystifying BS-VI’, Dr. Pawan Goenka, M&M Managing Director, said that certainly the cost for diesel engines will be higher, but it won’t become exorbitant as people are made to believe. With the preparation that began in 2016, the company is well prepared to launch its BS-VI-ready vehicles before April 1, 2020.

He added: “The diesel cost increase will be more than petrol, but it is not so much that diesel vehicles will become unaffordable. We will bring the first gasoline BS-VI vehicle by the end of the second quarter of this year. The BS-VI-compliant diesel should be available by the end of December or January.” Notably, the company has worked on 8 engines, 16 platforms and 38 variants for diesel, in BS-VI and 8 engines, 8 platforms and 12 variants for gasoline.

Despite this, the only engine that M&M will stop would be for the Jeeto Van as the cost parameter would be a bit high in order to meet the new emission standards for that segment. It will also not be possible to club ABS and airbags in the vehicle, as it won’t be affordable for the segment. They will also not carry forward the engine for the KUV 100 to BS-VI as the cost increase for the 1.2 litre diesel engine won’t be suited for the passenger vehicle segment.

The company has gone through a rigorous vendor development effort to meet the mammoth task. “It is clear that we cannot convert BS-IV vehicles with a few tweaks into BS-VI. All BS-IV vehicles that remain unsold post March 31, 2020, will have to be scrapped. Based on the BS-IV stocks available till the end of November-December, we will decide on the ramping up of the BS-VI components,” said Dr. Goenka.

Behind the scenes

What complimented the Rs. 1,000-crore plus investments was a dedicated team of over 700 people who worked for more than three years fine-tuning over 2,000 components. The entire project was carried out at the Mahindra Research Valley in Chennai that is equipped with 14 state-of-the-art performance and emission test benches, advanced data and analytics tools and automated test runs.

Not to forget the excellent vehicle testing facility boasting of test labs, chassis dynamometer and real driving emission measurement systems. In the process, M&M took consultation from AVL, Bosch and Delphi as well as from suppliers like BorgWarner, Tenneco, Valeo, Delphi-TVS, Magneti Marelli and Garret, amongst others.

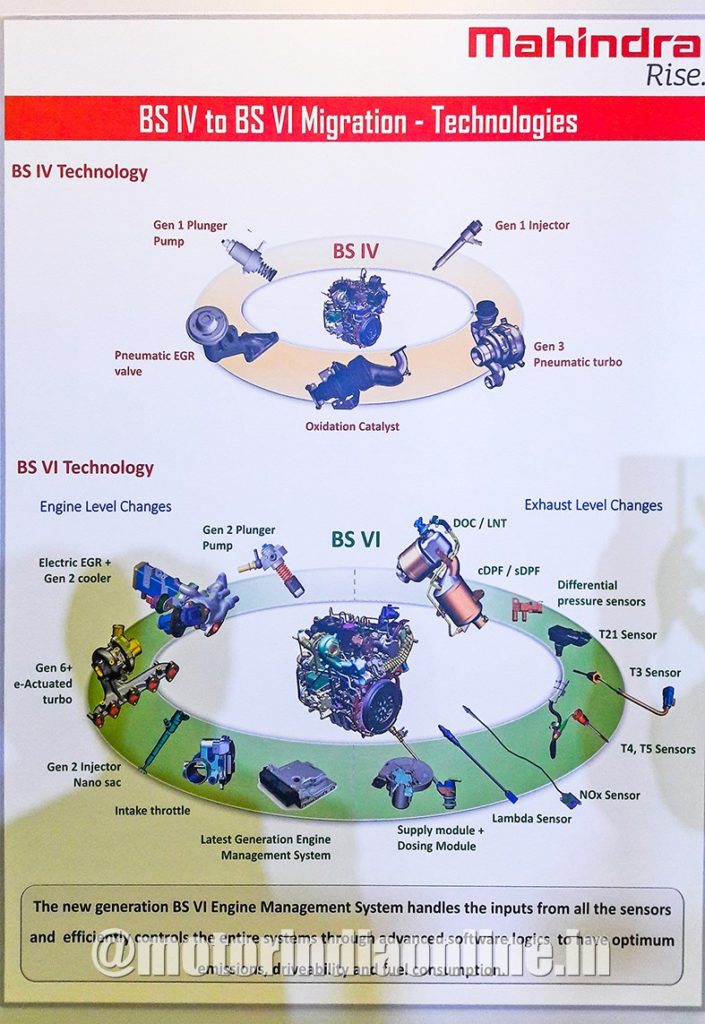

The task included the recognition and choice of technology from options like Lean NOx Trap (LNT) and Selective Catalytic reduction. The torque and mileage would dictate the choice as per the application as for different vehicle platforms. The Engine Control Module or the Engine Control unit had to be improved to meet the new NOx norms. While doing so they also had to ensure that the driveability, fuel efficiency and NVH levels are not compromised.

The company used all the next-gen design for reducing friction in different parts such as vacuum pump, oil pump, valves, crankshaft, piston rings, torque plate honing among others, which resulted in a whopping 30 per cent friction reduction and improved fuel efficiency. The important factor that cannot be neglected was the cost escalation.

Dr. Goenka disclosed: “We decided that if we can manage the 0.6X of the cost incurred by the European manufacturers for BS-VI engines (X being the minimum cost of the transition) it will be quite a big plus. We are happy that we could manage with 0.5X cost increase only.”

M&M started in March last its fleet validation by deploying 136 vehicles across 11 validation locations in different road and weather conditions across India, to clock over 69 lakh km cumulatively to get the BS-VI calibration correct. It is evident from the efforts that M&M is well-prepared for the BS-VI transition.