Fuel savings, easier gear shifting facilitated

Oerlikon Graziano has developed a family of state-of-the-art synchronizers for heavy duty truck transmissions that sets new standards for fuel efficiency and ease of shifting. The first application of the technology, on new 9-speed and 14-speed premium gearboxes, has improved transmission efficiency by around 10 per cent, saving fuel and reducing CO2 emissions. Already a leading supplier to the agricultural and construction industries, Oerlikon Graziano expects the high-efficiency synchronizers to generate significant new business in the heavy truck market.

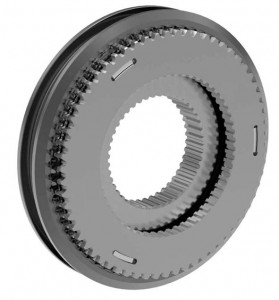

The new synchronizers save fuel in two ways: by optimizing the shift to minimize torque interruption and by reducing steady-state drag torque in the transmission. They combine the high durability and high performance of Oerlikon Graziano’s existing long life synchronizers with a new internal activation system that uses optimized clearances and lubricant paths for higher efficiency.

“Most new transmissions carry over existing synchronizer designs which limits the scope for efficiency improvements,” said Andrea Serra, product manager, synchroniser and powershift design, Oerlikon Graziano. “Our new synchronizer technology offers a step-change improvement in fuel efficiency for the next generation of heavy duty transmissions.”

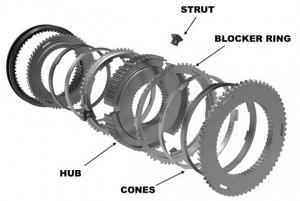

The new synchronizers are configured in single and double cone arrangements, each with the same external geometry to allow great flexibility in transmission design. In all, four different synchronizer specifications are used on the 14-speed transmission and three on the 9-speed. The synchronizers have exceptionally high torque capacity – up to 18000Nm in the first applications – and use molybdenum-coated steel cones for high durability with optimum friction. Future developments include the potential for carbon coating.

A key feature of the new technology is the activation system which is integrated into the synchronizer and optimized for smooth engagement. Applications are usually manual shift with air assistance, so any shift problems are immediately obvious to the driver. The new system ensures a fast, smooth and reliable shift under all conditions, making it an attractive alternative to a powershift system because it packages into a much smaller space.

By increasing the speed of a manual shift, Oerlikon Graziano has been able to reduce the torque interruption, keeping the engine at optimum efficiency for longer and reducing engine transients to save fuel.

Whichever gear is selected, large differences in rotating speed can exist across the other synchronizers. With a conventional design this leads to significant drag losses which impair efficiency, but the new synchronizers greatly reduce this effect to further improve fuel economy.

The new synchronizers improve the shift process during three distinct phases. Prior to synchronization, the integrated activation system provides optimized load characteristics to give improved consistency and outstanding durability, compared to a standard design.

The second phase, synchronization, has been shortened by the use of multi-cone technology, best-in-class friction materials and the optimization of geometries and tribological properties.

The third phase, from synchronization to engagement, has been improved by incorporating new internal features allowing smoother travel of the sliding sleeve, avoiding blocking problems and providing a more friendly engagement feel to the driver.

“Our priority is to develop transmission technologies that allow our customers to introduce more capable and competitive vehicles, whether for cars, trucks or off-road applications. The new synchronizers will support the next generation of truck transmissions with reduced fuel consumption and improved driver convenience”, added Serra.