Parker Hannifin is a Fortune 250 global leader in motion and control technologies with a legacy of over 100 years. In India, Parker is headquartered in Navi Mumbai since 1993, and operates across multiple divisions, one of them being filtration. In an intriguing conversation with N. Balasubramanian, Parker Hannifin’s Burkhard Hartmann, Global Business Development Manager, Robert Jozsa, Product Manager of Alternative Technology, and Narayanan Raghavan, Operations Manager of India Filtration Group, revealed details about their company’s growing presence in the Indian market, strategic focus on Asia Pacific region, commitment to R&D, readiness for H2-ICE and fuel cell applications and lots more

Parker Hannifin is excited about its India business, primarily thanks to the sweeping changes in vehicular emission norms the country has seen in the recent past and the future technologies expected to take centre stage in the medium- to long-term future.

Starting off the conversation with an update on Parker’s presence in India, Burkhard Hartmann said, “I can start with an update on the Asia Pacific side, particularly the acquisition five years ago when Baldwin became part of the Parker family. Since then, our footprint has expanded in the Asia Pacific region. Today, at our Chennai facility, which was established in 2012, we have integrated Baldwin’s business for Euro 5 technology and now we are going into BS-VI Stage 2 technology for BharatBenz who is one of our major customers in India.”

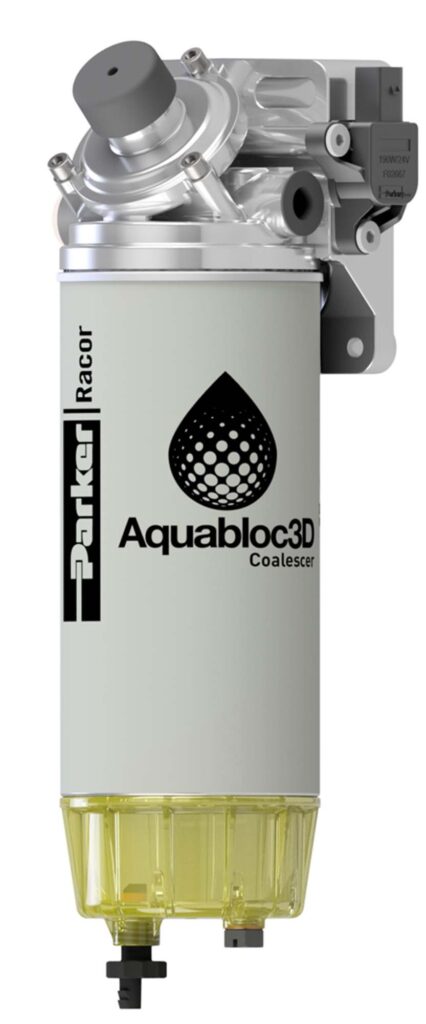

Hartmann further mentioned, “From a filtration standpoint, the transition to BS-VI stage 2 in India has been an important step for us. We have been pleasantly surprised by how quickly the Indian market has adapted to the new norms. In terms of infrastructure, Parker Filtration has made contributions to highway filtration and has also worked on filtration systems for distribution filling stations, which do not provide this fuel level. We have also noticed significant changes in the use of biodiesel and the plants used for fuel, which has posed challenges for vehicle filtration requirements. Unlike in Europe or America, where biodiesel ingredients are consistent, the composition of biodiesel plants used in India varies. Therefore, it was a very challenging development for us to adapt our 3D multi-stage coalescer technology for the Indian market. Additionally, we have observed that our customers in India are selling their products outside the Asia Pacific region. Moreover, the fuel composition in India differs from that in Malaysia, which has added to the complexity of meeting emission requirements with filtration technology. As a result, this has been a two-year development process for us to successfully navigate and adapt our product to the market requirements.”

As per the emission regulation for Euro-VI (BS-VI) norms, the end-of-life filtration performance should be good enough to deliver a water separation level of at least 80%. Hartmann explained, “While a new filter would easily be able to deliver such a performance, the challenge is in ensuring the required performance is delivered at its end-of-life. This is where Parker’s three-stage coalescer technology is a market leader globally. This technology is proven and has been successfully implemented with our privileged customers like Daimler across various markets, including Brazil, North America, China, Europe, and also India, which demonstrates its effectiveness on a global scale.”

Strong Customer Base

Speaking about the Chennai facility, Hartmann explained that they established the facility in 2012 primarily for Daimler. However, the company later expanded their customer base to include Volvo as well. Parker Filtration has been supplying Euro VI filters to Volvo Europe from the facility since 2013. They have also expanded their supply to Brazil, Europe, and Volvo’s partners, including UD Trucks.

Additionally, Parker Filtration acquired a 50-year-old company called John Fowler, based in Bengaluru, which had a legacy business serving the defence segment. They successfully integrated John Fowler’s businesses and retained their customers, including BEML, whom they continue to supply to for defence applications. Furthermore, they acquired Racor, a company that is part of Baldwin, which added JCB to their customer list. Overall, since their establishment in 2012-13, Parker Filtration’s India business has clocked consistent growth with a CAGR of 20 per cent.

The Chennai plant has an installed capacity of approximately 3 million filters per year of which of typically only around 30 per cent is utilized, leaving significant room for expansion.

In terms of their domestic and export distribution, the ratio stands at 40:60 in favour of exports, with the company shipping its filters to customers in various regions including Europe, Brazil, Southeast Asia, and Japan.

Talking about Parker’s major OEM customers in the domestic market, Narayanan Raghavan said, “We supply to Volvo-Eicher, Scania, and JCB and provide filters for highway applications, including gensets where Kirloskar is one of our prominent customers. In the off-highway sector, we serve numerous customers, including JCB, Hyundai Earthmoving, Volvo CE, Tata Hitachi and Kobelco. We have customers in the defence segment as well with BEML being one of the most prominent ones.”

Tech-Ready for the Future

Discussing the importance of R&D, Hartmann highlights that Parker Hannifin has a global design and manufacturing approach for filters. This is crucial because their global customers demand consistency in their product lines. Additionally, Hartmann emphasizes that different markets will require different solutions as electrification progresses. In India, for example, the well-established combustion engine technology will continue to be utilized, but alternative energies such as CNG and H2 will also play a role. Parker’s R&D team is working closely with partners and customers to be prepared for engineering design and implementation, especially in modifying current combustion engines for alternative energy sources like H2. This requires a 25 to 30 percent redesign, including adaptations to filtration products like its latest ‘super impactor technology’ used in crankcase ventilation. Parker aims to be ready to roll out these developments in India, not just in terms of global manufacturing but also in global R&D collaboration with OEMs and independent engine manufacturers.

Parker Filtration has an established engineering center in India which has been operational for the past ten years. The center works closely with global R&D efforts and ensures that adaptations are made to meet the specific requirements of its domestic customers in the country.

According to Narayanan Raghavan, “Having engineering expertise in India is crucial for effective communication with local customers. While there is support from the global team, most of the R&D work is done in India. Some customers have a global presence and require interaction with the global team, while others are more localized and their development is handled in India. In some cases, technologies developed by the global team may need to be brought to India for specific applications.”

Robert Jozsa emphasizes Parker’s commitment to carbon emissions targets and delivering solutions for renewable energy and clean solutions. “In the field of mobility, fuel cell and hydrogen combustion engines are key technologies, especially for commercial vehicles. Parker has a strong focus on H2 and has a strong track record of developing H2 solutions. Our Indian engineers are collaborating with the global team to develop technologies and products for fuel cell applications and H2-ICE (hydrogen internal combustion engine) vehicles. While the availability of these technologies depends on market demands and regions, in India, H2-ICE is expected to be adopted first due to its easier implementation. Parker is working on technologies like the ‘super impactor technology’ for crankcase ventilation and also have a wide range of products, such as air cleaners, humidifiers, H2 separators, and water separators, to ensure stable performance and longevity of fuel cells.

Hartmann adds that they are already testing mature market-leading H2 ICE technologies in India. “Our products are being developed and will be implemented once ready. We have a decade of experience in developing filtration solutions for H2-ICE and are prepared for launch by the 2025-2027 timeframe. As ICE engines transition to becoming carbon-neutral, Parker’s product line will support this shift, which is expected to occur around 2026-2027. Our proximity to customers allows for close collaboration and integration of our products into their development processes.”

Betting on India

Parker Filtration considers the Asia Pacific region, including India, as an important market with significant growth potential. The company has facilities in China, Korea, and India which cater to the needs of the Asia Pacific market. Hartmann expects Parker Filtration’s India business to grow by a double-digit per cent keeping in mind the implementation of advanced technologies in the country where the company will have a major role to play. “I am proud of our Indian team and the infrastructure we have established in India over the past decade. I truly believe India has the capability to achieve self-sustainability by producing world-class quality products for both the domestic and global markets. India’s ability to quickly implement technologies and adapt to changing global trends is a key advantage. The shift towards decarbonization is a global concern and India is at par with other regions in terms of technological advancements such as H2 ICE engines and fuel cells. Of course, infrastructure development will be a key factor but if the government provides the necessary support and push, India has the potential to swiftly implement changes and implement these technologies faster than many markets.”