Rajesh Rajgor recently engaged in an insightful discussion with Nikesh Patel, Co-Director of Perfect Polymers, a company that has been a leader in the sealing solutions industry for over four decades. Specializing in elastomeric sealing technologies, Perfect Polymers manufactures a wide range of products, including wheel hub seals, engine seals, mechanical seals, and shaft seals for both rotational and reciprocating applications. During the conversation, Nikesh shared the company’s growth journey, its commitment to sustainability, and its technological innovations.

Perfect Polymers has been in the sealing business for more than 40 years, continuously innovating to meet the evolving needs of our customers. The company has become renowned for its low-friction sealing solutions, which enhance fuel efficiency and reduce carbon footprints in the automotive sector.

The company’s approach to sealing solutions is deeply customer-centric. “We believe in designing seals that meet the specific needs of each application, rather than offering off-the-shelf products,” he explained. This strategy, combined with substantial investment in cutting-edge technology, has positioned Perfect Polymers as a leader in the sector. With the capacity to produce over 33 million seals per month, the company is well-equipped to meet both domestic and international demands.

The company’s strategic investments in advanced technology and production capacity have allowed it to operate with more than 50% excess production capacity. This has put Perfect Polymers in a strong position to scale operations as demand increases, particularly in the European market.

“By introducing our innovative sealing technologies to the European market, we plan to demonstrate that Indian products can meet and even exceed global standards,” said Nikesh. Perfect Polymers is confident in its ability to break the long-standing perception that Indian products cannot compete with European counterparts.

Revolutionizing Seals, Driving Sustainability

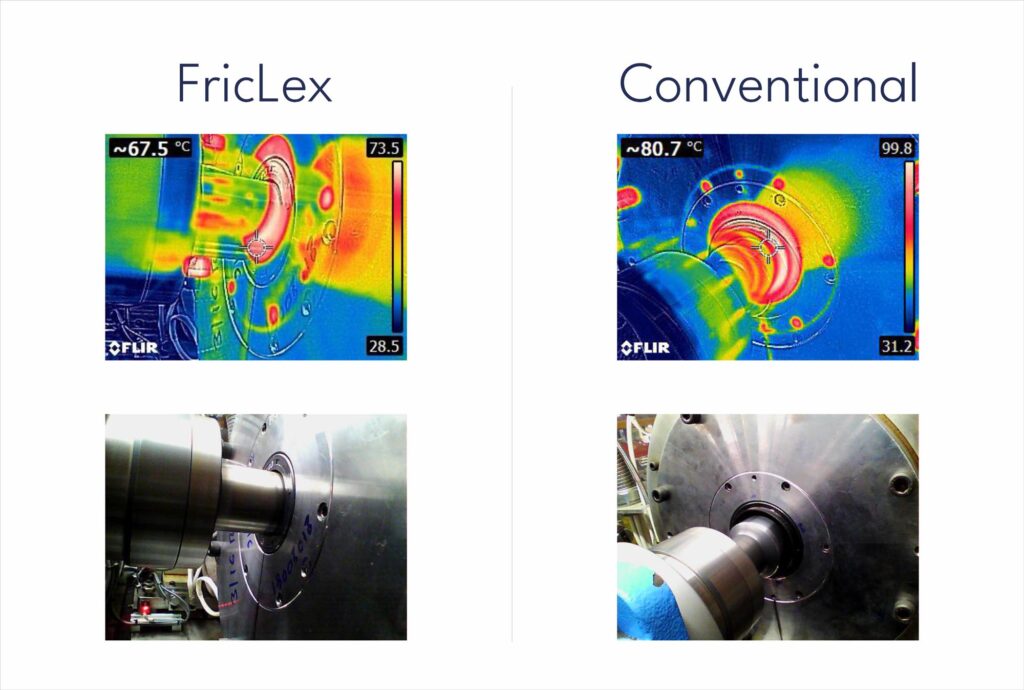

A key innovation at Perfect Polymers has been the development of seals that exceed industry standards. Through continuous advancements in material technology, design, and process, the company has created low-friction, long-life seals that set new benchmarks for durability and performance. “Our focus on innovation enables us to deliver seals that not only meet but surpass customer expectations,” he said.

Reducing the carbon footprint remains a central goal for Perfect Polymers, especially with the automotive industry’s shift toward electric vehicles (EVs). The company has risen to the challenge by introducing new materials and technologies that are compatible with the latest EV designs, enhancing both performance and sustainability.

“As the industry pivots towards EVs, we are introducing new materials and technologies to stay ahead of market demands,” Nikesh said. This adaptability is a key factor in Perfect Polymers’ success as it continues to serve both domestic and international markets. Currently, the company exports to developed countries and plans to expand its footprint in the European market with a focus on innovative sealing solutions.

Over the past three years, Perfect Polymers has achieved an impressive year-on-year growth rate averaging around 25%. “Our long-term goal is to continue strengthening our presence in the European market, with an aim to achieve a 60-40 split between domestic and international sales,” Nikesh highlighted.

With its diverse product portfolio serving both commercial and passenger vehicles, a strong focus on OEM supplies, and an expanding presence in aftermarket sealing solutions, Perfect Polymers is positioning itself for further success. “We continue to invest in advanced manufacturing processes and maintains a customer-first approach to meet our ambitious global goals,” Nikesh concluded.

As the sealing industry evolves, Perfect Polymers remains at the forefront of innovation, committed to providing high-performance, sustainable solutions that meet the demands of tomorrow’s automotive landscape.