Pi Green Innovations P Ltd.’s Carbon Cutter and RepAir are ground-breaking products designed in particular for automobiles and generators because they release the most particulate matter. According to the manufacturer, their solution cuts PM 2.5 to PM 10 particulate matter emissions from generators and automobiles by more than 90%. Rajesh Rajgor interviews Irfan Pathan, the Founder and CEO of Pi Green Innovations, to learn more about their business and products

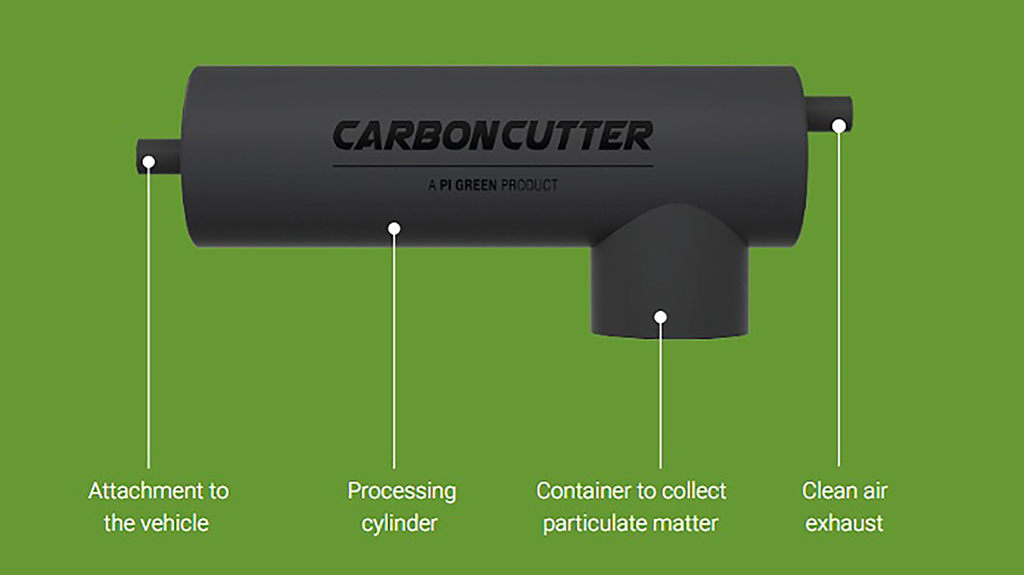

With an aim to create a clean-tech business, Pi Green Innovations was established with the goal of developing technologically advanced products that decrease particulate matter emissions (PM 2.5/10) both at the source and from ambient air. One of the company’s main products is Carbon Cutter machine, which is a retrofit for heavy vehicles and diesel generators. RepAir, a filterless ambient air-purification tower that may be put in public areas is also created by Pi Green. Irfan Pathan, Founder and CEO, says: “The Carbon Cutter and RepAir operate on the same patented technology and present several USPs, the most significant being ‘filterless’ which, apart from delivering consistent results, reduces the operation and maintenance cost significantly to near-zero.”

“Also, we do not use any solvent or water in the process of capturing carbon which is in line with our guiding principle of not cleaning the air at the cost of wasting other elements (water) which is scarce,” he adds. Today, the young company is looking at various opportunities to optimize the value chain, which will positively impact the existing cost structure across automotives and DG sets. They have already been working with corporates using DG sets.

Products and Technology

Pi Green Innovations aims to enable government agencies and organisations to solve the problem of a serious public health concern in the form of air pollution as part of its mission to make clean air available to everyone. The business is dedicated to developing long-term solutions for a greener future. Products that offer a cleaner environment are developed locally using advances in technology and design. The products have no filter, hence avoid issues like choking, cleaning maintenance and replacement.

“We are proud that our ‘filterless’ technology with patents granted in over 30 countries including India is entirely ‘Made in India’. With a few exceptions, all the components are also locally sourced. We have completed ISO standard testing of the products in government-approved labs and demonstrated measurable results in reducing particulate matter, which is the most harmful component of air pollution. Very few companies in India complete these tests, and we are one of them,” reveals Pathan.

It must be noted that in real time this filterless retrofit fully automatic and compact device, called as Carbon Cutter, simply needs a plug in installation and can be connected to the exhaust of any vehicle. It cuts down over 90% of particulate matter at the source and the smallest of the particulate matter is captured and collected in a container in powder form and can be converted into useable elements like paint or ink. As a part of the innovation, Carbon Cutter has an inbuilt smart integration system. The concerned authority gets a notification through SMS when the residue container is full and needs to be emptied.

In addition to the particulate matter emissions from vehicles and generator sets there is a huge amount of dust smoke and other harmful particles suspended in air that affect our environment and health. To overcome this problem the company offers a product called ‘RepAir’. Like Carbon Cutter, RepAir too is a filterless ambient air purifier that helps clean the air by capturing particulate matter, dust, smoke and any other form of air pollution. It takes in the surrounding air from which the particulate matter gets conglomerated using scientific methods and due to the self-cleaning mechanism it gets stored into an inbuilt box which can be detached and cleaned easily.

“RepAir gives out 80% cleaner air and has an inbuilt smart integration system which informs the concerned authority via SMS when the container is full and needs to be emptied. It can be installed at locations with a high density of population and vehicular movement as well as at places with maximum footfall. The size of RepAir can be customised from 9 feet to 45 feet in height as per the requirement,” he informs. It can be used for advertisements incorporating smart branding showing public welfare messages and maximising brand exposure thanks to its sturdy exterior surface, which is waterproof and offers high ingress protection and low maintenance.

RepAir is a marvel product that is easily adaptable to other functions, such as a reverse vending machine for plastic bottles. Smart bus stops and CCTV cameras help government organisations achieve their objectives for improved public health and services. Additionally, RepAir supports businesses in their CSR programmes, which have a significant positive social and environmental impact.

Manufacturing Footprint

Pi Green Innovations was incorporated in 2019 and began its commercial production in 2020. Since starting this journey, the company has successfully installed 150 products in Tamil Nadu, Andhra Pradesh, Gujarat, Maharashtra, Goa and Delhi NCR on DG sets with capacity ranges from 125 kVA – 2,500 kVA. “We have initiated conversations with relevant authorities in Poland and the UK where there is potential to develop products to address the specific challenges faced regarding air pollution,” Pathan reveals.

Probe him on the cost-sensitive Indian customer profile and how Pi Green Innovations packages their products to make them affordable and at the time scalable for Indian consumers, he adds: “India traditionally has been a very cost-sensitive market for all products. When we speak of environmental initiatives, very few takers are enthusiastic about spending money for the greater good. Thus, we intend to involve the corporate sector in strategic tie-ups to achieve sizable volume to optimize costs and explore the opportunity of utilising their CSR funds toward initiatives like providing after-treatment solutions for crematoriums.”

At present the company operates out of a 50,000 sq. feet production facility in Chakan near Pune. “Our current capacities allow us to manufacture 400 Carbon Cutter machines for DG sets. We have a few strategic tie-ups that enable us to reach out to customers in various parts of the country. Our pipeline for DG set retrofit is running into a few hundred crores. We look to close the current FY with a turnover of Rs 100 crore with a small but strategically important contribution from international sales,” he states.

The Carbon Cutter for DG sets has currently been commercialised by the business. Therefore, they serve major organisations that use DG sets with large capacity. “There is currently no need for extensive training to be given because our devices are made to require no intervention once they are installed. To help the teams better understand how the product functions, we conduct product testing and brief them from the customer side at the time of handover,” wraps up Pathan. The company’s revolutionary innovation has been rated as one of the best technologies globally to reduce air pollution at Smogathon 2018 in Poland and has also won several other industry awards. It received over USD 4.5 million in Series A fundraising in 2021. The director of Morde Foods, Harshal Morde has already contributed USD 300,000 for start-up costs.