The Pittsburg-based PPG, established in 1883, is a global maker of paints, coatings, optical products, specialty materials, chemicals, glass and fiber glass. It has 38,000 employees spread over 60 countries. From the very beginning, the company maintains its focus on value-driven products that accounted for its emergence as one of the leading painting and coating manufacturers in the world. A $14 billion company, it has 13 strategic business units in six major product areas, of which automotive which is part of the Industrial Coating Division contributes 28 per cent.

The Pittsburg-based PPG, established in 1883, is a global maker of paints, coatings, optical products, specialty materials, chemicals, glass and fiber glass. It has 38,000 employees spread over 60 countries. From the very beginning, the company maintains its focus on value-driven products that accounted for its emergence as one of the leading painting and coating manufacturers in the world. A $14 billion company, it has 13 strategic business units in six major product areas, of which automotive which is part of the Industrial Coating Division contributes 28 per cent.

A perfect partnership

In India, PPG set up a joint venture with Asian Paints 15 years ago in the name of Asian PPG Industries Ltd. (APPG) that grew consistently over the years. Considering the accelerated activities of the Indian automotive industry, the company has expanded its operations at its Sriperumbudur plant near Chennai. Its current OEM customers include Ford, Tata Motors, Ashok Leyland, Mahindra & Mahindra, GM, Honda, Hyundai and Volkswagen.

PPG has plans to launch its high technology products in India which can help the local OEMs to achieve world class products. The company is also looking at establishing new production facilities either in Pune or somewhere in Gujarat.

These and other company-related developments were shared by the officials with Mr. R. Natarajan, MOTORINDIA Managing Editor, during his recent visit to PPG’s Technical Center and paint color studio situated near Detroit.

He was also delighted to learn that PPG has won the R&D 100 Award nine times during the last 14 years, clearly confirming the company thrust on new product development and technology. Interestingly, 41 per cent of its auto OEM sales is accounted for by the new products developed in the last five years. Growth of the automotive coatings is more or less determined by new product technology, energy cost, durability, environment, appearance, etc.

True, PPG is a value-driven, integrated, market-oriented enterprise, with consistent sales and earnings growth with its main focus on coatings and specialty products. The company owes its success to its dedication to the customer, the recognition of the concerns and needs of society, value of the supply chain relationships and its responsibility to the shareholders. Last year, PPG announced its expansion of APPG to create a second 50:50 joint venture.

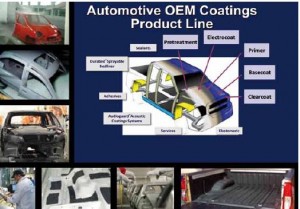

The OEM coatings product range covers sealants, adhesives, acoustic coatings systems, electrocoat, primer, basecoat and clearcoat. The PPG footprint covers 90 per cent of global production of automotive coatings. The global market leader expects domestic consumption in India to grow substantially. The current exports estimated at 15 per cent are expected to rise in view of India emerging a small car hub and multiple OEMs considering expansion of their Indian plants.

Demonstrating innovation, sustainability

PPG leads the market in offering a variety of scratch and etch-resistant clearcoat technologies that not only meet the rigorous requirements of automotive manufacturing facilities worldwide, but also help vehicles retain a showroom-like finish for a longer period of time.

CeramiClear was the first clearcoat to use nanoparticle technology to achieve a previously unattained level of scratch, mar and etch resistance.

Patented technology creates an impressively hard surface that provides superior resistance to damage caused by day-to-day use, car washes, and environmental hazards such as acid rain and tree sap.