At Auto Expo 2023, Rotex Automation, a prominent producer and supplier of fluid control systems, positioners and electro-hydraulic actuators, displayed its assortment of specialised technologies for the automobile sector. Nirav Shah, Director, Rotex Automation was interviewed by Rajesh Rajgor to learn more about the exhibits and the overall performance of their business

Rotex Automation is in tune with the changing trends in the automotive industry. The company has built solenoid valves which critically clean the sensors with air or water. “We have supplied over 5,000 samples to Germany and trials are underway. We are also making solutions available for hydrogen since hydrogen ICE will surely be sweeping the market in a bigger way very soon,” informed Nirav Shah, Director, Rotex Automation. The company has also been supplying to cater to Euro VI norms in Europe and now Euro VII. On similar lines it is ready to serve the Indian market which is currently at the level of BS VI in terms of emission norms.

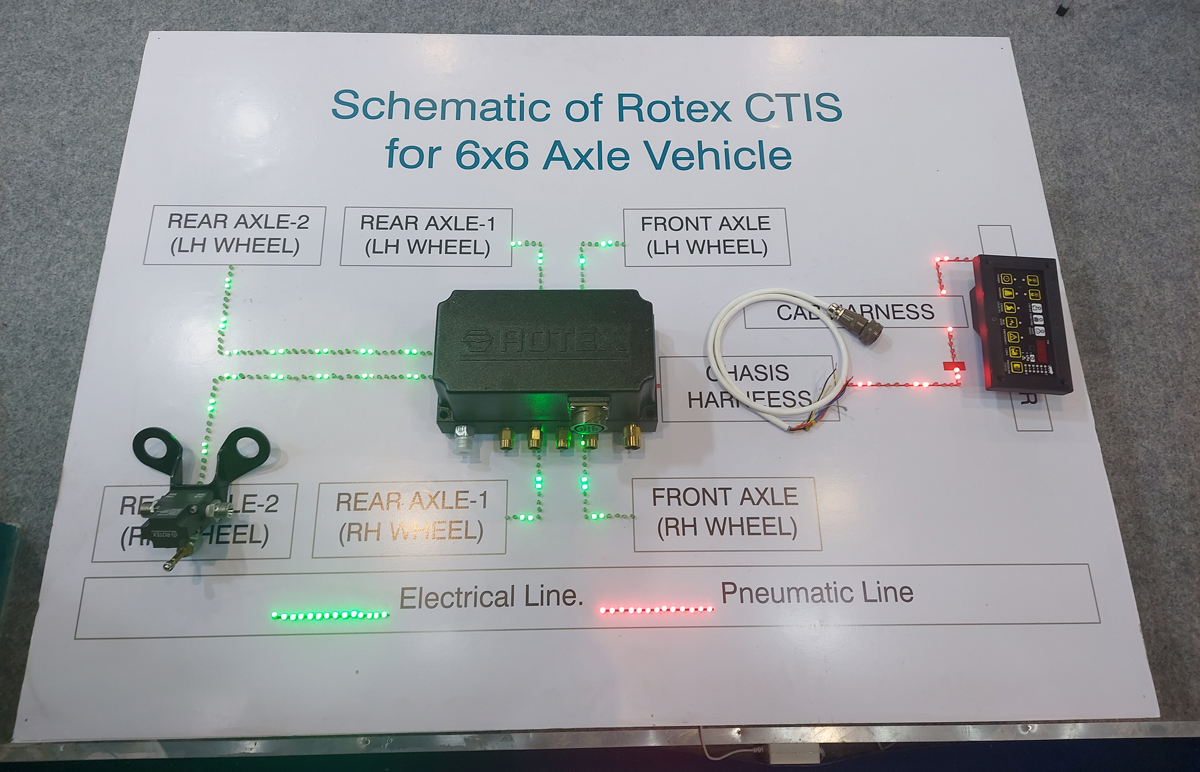

Looking at 2023, the company is positive about doubling its turnover. “We have just touched growth of almost 80% and the next year’s plan is to have almost 100% growth over the previous year. With lot of new product development like CTIS which is a system for tyre inflation and deflation, CCV valves for tipping application, valves for ADAS, valves for cooling application in electric vehicles and valves for after-treatment under progress, we will be able to create greater value for the industry,” Shah said.

Product Display

One of the new product developments which Rotex Automation has carried out last year is a hydrocarbon doser unit. “One can see the future of the metering valve and the air valve inside one and it goes into the engine and then into the vehicle. It directly fits into the emission system for DPF regeneration. There is also a version of the hydrocarbon dosing model for the US’ market,” Shah informed. The company also showcased CTIS, a centralised tyre inflation system, which is basically a system that can inflate the tyre pressure as well as deflate it. The air pressure in tyres can be controlled on demand thanks to CTIS.

It is crucial that the tyres offer grip to keep the vehicle moving in challenging operating circumstances as in deserts, snowy, muddy or wet terrains, and off-road activities and under varied load conditions. The ability of the central tyre inflation system is to change the pressure inside the tyre and achieve the ideal tyre footprint that aids in getting the traction necessary for ongoing mobility. “This is very critical when you are dealing with trucks which are engaged for mining activities or off-highway applications or maybe a defence vehicle. You might need to have truck which can function on various terrains. This particular system manages the entire pressure operations,” Shah elaborated.

“If the truck is in an area which is experiencing snowfall or is in an area which has a lot of sand cover, the tyre pressure has to be different in both such scenarios. As such, with just a click you can increase or reduce the pressure and make the vehicle tackle any terrain,” he further said. Rotex Automation also showcased its valve for SCR applications and a product with ultra-low sound. The valve for SCR application is a proportional valve where one can vary the flow rates as per the duty cycle or the current supply.

“The product is into mass production and widely used for SCR application. We have another valve that doesn’t make a sound even with a click and is very important when it comes to autonomous vehicles. Autonomous vehicles are electrical and at the same time they would need to have a very reliable and ultra-low sound level. We have supplied 5,000 valves for autonomous vehicles that are under customer trials,” Shah said.