India’s premier engine anti-freeze coolant and brake fluid maker is eliciting awareness on the essential link between regular fluid maintenance and enhanced vehicular life and safety.

In the initial years of liquid-cooled engines, a miscellany of simple compounds were tried as coolants, as mere water proved ineffective at extreme temperatures – mostly household and kitchen ingredients like honey, sugar and molasses! The idea was to simply push the boiling and freezing points of the water to the extremes as much as possible, so that heat transfer from the engine case happens even at sizzling desert temperatures, while the engine also catches up when cranked at freezing winters.

Then came the all-season ‘anti-freeze’ coolant made from ethylene glycol sometime in the late 1920s. It is no exaggeration to say that this invention led to the advancement of the internal combustion engine in the next 100 years to come, even today. To the extent that our modern day automobiles necessary have to boast their radiators in the windward side (front) of the vehicle, may it be rear-engined Volvo 9400 or mid-engined Porsche 911 GT1! The role of antifreeze coolants in an engine´s cooling system is phenomenal.

It is said that the coolant system wards off almost 30 per cent of the combustion heat of heavy duty engines used in commercial vehicles, while more than 50 per cent of premature engine failures in heavy vehicles are attributed to improper maintenance of the cooling system. For instance, modern-day coolants feature certain additive packages to prevent rusting and corrosion in the system, especially to foil cavitation in wet cylinder sleeves in diesels. Further, therefore, a proper understanding of what coolant is being used in a vehicle and in what formulation (ratio of water mix), along with the awareness of when to replace the coolant is essential for any equipment owners and fleet managers. But, many truck and bus owners and drivers in India may have no idea of what goes on in their vehicle´s cooling system! Unlike engine oil and other lubricants, coolants hardly get maintenance attention they truly deserve.

If that´s the case for coolants, then think about brake fluids that is also considered as a low-key affair in vehicle maintenance. Although not applicable in heavy-duty commercial vehicles, brake fluids are used notably in light commercial and passenger vehicles, and in cars they are the norm. Present-day brake fluids are Glycol-ether based, therefore hygroscopic, meaning they absorb moisture from the air. This results in contamination of the fluid, especially in tropical climates like ours with high humidity. Further, they must have high boiling point and maintain constant viscosity across a range of extreme temperatures, while their anti-corrosion additives must stay intact for prescribed periods to protect vital components like wheel cylinders, master cylinders, calipers, and ABS control valves. Else, the leakages in fluid or pressure may occur, components may get damaged, resulting in brake failure. Although it is not common for a vehicle to suffer absolute hydraulic brake failure and related accidents are relatively rare, brake failure is still is notable factor for accidents that often goes unrealized.

Largest maker of anti-freeze coolant

“There is a dearth of awareness on regular coolant and brake fluid analysis among the users in their vehicles, as they fail to realize the essential link between these fluids and the vehicular life and safety”, says Mr. S.K. Singh, Director of S-CCI India Pvt. Ltd., that is an authorized licensee of the ‘Golden Cruiser’ brand of anti-freeze and brake fluids in India. We are trying to engender best maintenance practices and right perception of high-quality anti-freeze coolants and brake fluids among the OEM dealers, independent workshops, and end users, so that the incidence of overhead-induced engine failures and braking effeteness can be prevented, he adds.

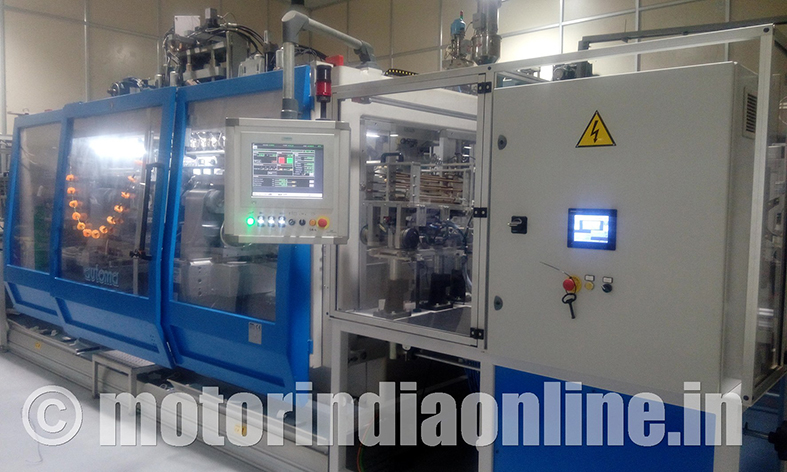

S-CCI India is taking several initiatives in this regard. During the 4th UN Global Road Safety Week 2017 in May this year, the company ran a series of campaigns to support the use of high quality brake fluids and anti-freeze in cars and commercial vehicles. S-CCI India is perhaps the largest manufacturer of automobile antifreeze coolant in India, also holding a substantial share in the country´s total production of high quality brake fluids. It is a joint venture with CCI Corporation of Japan that owns the ‘Golden Cruiser’ marque of engine antifreeze coolants, brake fluids and other specialty chemicals. The firm boasts two production units in India – Bhiwadi (Rajasthan) and Sitarganj (Uttarakhand) – while export distribution networks are extended to Bangladesh and Nepal as well.

In the OEM space, S-CCI Golden-Cruiser India is the supplier of anti-freeze and brake fluids to various brands, including Komatsu, MAN Trucks, Tata Motors, Force Motors, SML ISUZU, AMW, and TAFE in the CV segment among other passenger car makers. In the aftermarket, the company has over 150 distributors across the country, apart from tie-ups with various State Transport Undertakings (STUs) for antifreeze coolants. The company’s market share is pegged at over 70 per cent collectively across all vehicle segments in India. “The OEM business contributes to over 80 percent of our revenue, as the dealer-oriented sales channels are vibrant in the recent times with more and more customers using authorized service stations”, observes Mr. S.K. Singh.

“Acceptability of our products among automakers is tremendous, as we are the pioneers of antifreeze coolants in India and our constant technology and quality upgradation of ancillary products and consumables to the international levels is well recognized”, he adds.

For instance, Golden Cruiser offers ‘Heavy Diesel´ anti-corrosion coolant recommended for trucks, buses, and off-road vehicles. The company claims it to be highly advanced, featuring slow-depleting organic acids that guarantee full anti-corrosion protection for longer periods even in harsh conditions. Quite recently, the company came up with ‘Extreme’ long life anti-freeze coolant with unlimited mileage for over 3 year replacement period.

“The technology is advancing towards longer service life and absolute protection from corrosion and cavitation as the engines are becoming more complex and sensitive”, notes Mr. S.K. Singh, also adding that S-CCI India’s constant R&D and testing efforts goes hand-in-hand with the evolution of technology.