It was an idyllic choice for the ‘Global Lecture Series 2014’ organised by the tech giant and world leader in the lubricants domain, Shell Lubricants – venue being one of the revered and much sought-after institutes for technological education and research, IIT Madras. It was an apt platform for the industry and academia to get together and examine and share ideas pertaining to lubrication & automotive co-engineering approach to meet the energy challenge. Driving thro’ the winding tar road penetrating the verdant forest like ambience of the campus, with occasional deer crossing the path and leading to a pleasant deceleration, it was a welcome sojourn amidst the busy life unfolding in the concrete maze of a metro city – deliberations venue was IC & SR (Industrial Consultancy & Sponsored Research) department auditorium. The place was buzzing with young minds and experienced professionals raring to go and take part in the India’s 1st lubricant technology lecture program organised by Shell and IIT Madras – to highlight the importance of collaboration of research teams with OEMs and customers right from the early stages to address the energy challenges.

The event started off with Prof. Krishnan Balasubramanian, Dean IC&SR, IIT Madras, welcoming the diverse audience from industries, OEMs, media, IIT faculty and students. He said: “We are proud to host the Shell Lubricants Technology Lecture at IIT Madras for industry experts who are at the forefront of automotive technology in India. Education and practical experience go hand-in-hand and this type of technical knowledge sharing is vital for the development of India’s future engineers”. He pointed out to IIT’s dedicated/specialised infrastructure facilities and the repository of vast technical talent available for the interactions and close collaboration with the industries-in spreading technology which was the need of the hour. He added that to address the important issue of energy challenge, the topic for the deliberations, research approach needed was multi-fold, viz., focusing on energy conservation, using the energy efficiently without sacrificing the need by reducing fuel consumption and at the same time in a responsible way – by not polluting the environment and enable in sustaining it.

Mr. Nitin Prasad, Country Head, Shell Lubricants India, inaugurating the event focussed on “Why are we here today?” He said: “The Shell Lubricants Technology Lecture is a great platform to collaborate across media, academia and industry on how lubricants can be used as a valuable design parameter in the automotive industry as opposed to an afterthought. I am very glad to see such an impressive turn out and hope we can continue to share knowledge delivering greater fuel efficiency and lower emissions in the Indian automotive industry”. He pointed out that to meet the growing energy challenge, it was important to develop new technology in engines, fuels, materials, lubrication and emission control-and all these around the central platform of fuel economy and energy efficiency.

Mr. Nitin Prasad, Country Head, Shell Lubricants India, inaugurating the event focussed on “Why are we here today?” He said: “The Shell Lubricants Technology Lecture is a great platform to collaborate across media, academia and industry on how lubricants can be used as a valuable design parameter in the automotive industry as opposed to an afterthought. I am very glad to see such an impressive turn out and hope we can continue to share knowledge delivering greater fuel efficiency and lower emissions in the Indian automotive industry”. He pointed out that to meet the growing energy challenge, it was important to develop new technology in engines, fuels, materials, lubrication and emission control-and all these around the central platform of fuel economy and energy efficiency.

Dr. Selda Gunsel, Vice President of Shell Global Commercial Technology, speaking at the event said that energy demand by the year 2050 would double due to population growth and the increase in the no. of vehicles on the road. The likely scenario will be movement towards cities and towns with over 75% urbanisation, leading to the strain on the energy requirements. “At Shell, we believe lubricants alongside new fuel and engine technologies have a unique and vital role to play in meeting the global energy challenge. Our research shows that fuel economy can be improved by using the most suitable quality lubricant for an engine and that even higher savings can be achieved when the lubricants provider and the automotive original equipment manufacturer or OEM, work together to develop bespoke products for a particular vehicle. This involves long-term co-engineering projects within the industry”, added Dr. Selda Gunsel. She also highlighted the relationship between various technical parameters like friction, wear rate, viscosity and oil film thickness in the choice of the right lubricant for the application.

Co-engineering was further reinforced by Professor Gordon Murray, renowned F1 (Formula One car racing) and McLaren designer as well as the Chief Executive Officer and Technical Director for Gordon Murray Designs (GMD). He talked about the impact of design culture and attention to finer details in his career spanning over 4 decades in the development of sports cars and concept vehicles. His passion for motor sport started very early and was involved in developing varied models in South Africa till 1969. He then moved to the UK and joined Brabham. He was with them as Tech Director for about 16 years (winning F1 team & driver championship 2 times) and later with McLaren for about 19 years (winning F1 team & driver championship 4 times with legendary drivers like Alain Prost & Ayrton Senna in the team) before establishing his own company. His association with Shell has been for a very long period in developing varied innovative lube systems including the dry sump gear box- oil taken out of transmission, cleaned and pumped back to the required points. He pointed out that less than 30% of IC engine power was utilised for vehicle operations and in F1 over 200 HP lost due to friction! Though thro’ big and small ideas design improvements can be effected, considering the regulations in F1 and the imperatives of working within the boundary of constraints, the focus was invariably on small ideas; and hence the continuous co-operation with Shell in improving the lube oil and systems for achieving efficiency impacts. This philosophy of improvements/developments around small ideas platform has been effectively used in his other auto projects and is the future, he added. “At GMD we are developing innovative cars that challenge every aspect of car design concepts, including lubrication. A lubricant is a vital engine component that has more potential than most for improving a vehicle’s fuel economy and cutting its CO2 emissions. That is why we have been working closely with Shell as technical partners since 2010. We share the same drive for fuel efficiency and innovation in an energy challenged world”, summarised Prof Murray.

Co-engineering was further reinforced by Professor Gordon Murray, renowned F1 (Formula One car racing) and McLaren designer as well as the Chief Executive Officer and Technical Director for Gordon Murray Designs (GMD). He talked about the impact of design culture and attention to finer details in his career spanning over 4 decades in the development of sports cars and concept vehicles. His passion for motor sport started very early and was involved in developing varied models in South Africa till 1969. He then moved to the UK and joined Brabham. He was with them as Tech Director for about 16 years (winning F1 team & driver championship 2 times) and later with McLaren for about 19 years (winning F1 team & driver championship 4 times with legendary drivers like Alain Prost & Ayrton Senna in the team) before establishing his own company. His association with Shell has been for a very long period in developing varied innovative lube systems including the dry sump gear box- oil taken out of transmission, cleaned and pumped back to the required points. He pointed out that less than 30% of IC engine power was utilised for vehicle operations and in F1 over 200 HP lost due to friction! Though thro’ big and small ideas design improvements can be effected, considering the regulations in F1 and the imperatives of working within the boundary of constraints, the focus was invariably on small ideas; and hence the continuous co-operation with Shell in improving the lube oil and systems for achieving efficiency impacts. This philosophy of improvements/developments around small ideas platform has been effectively used in his other auto projects and is the future, he added. “At GMD we are developing innovative cars that challenge every aspect of car design concepts, including lubrication. A lubricant is a vital engine component that has more potential than most for improving a vehicle’s fuel economy and cutting its CO2 emissions. That is why we have been working closely with Shell as technical partners since 2010. We share the same drive for fuel efficiency and innovation in an energy challenged world”, summarised Prof Murray.

Dr. Tim Leverton, Head of Advanced & Product Engineering at Tata Motors, focussed on the emission norms in the Indian context; and the need for new engine designs to address the same and fuel economy angles. He also indicated other sub-assemblies/concepts being looked into towards the above goals included powertrain, hybridisation, electronic architecture, etc. He said: “Driving conditions in India are very different than that in Europe and Tata is actively working with Shell to look into every aspect of current CV & PV engines, transmission, specs for new bearings, lube systems including brand new engine families to meet the emission norms”. Mr. Rick Finn, Corporate Strategy team of Infineum UK, a world leader in many of the products in its supply program spoke about his company being involved in the manufacture of additives used in lubricants and fuel; and the same playing a supportive role in contributing for the fuel efficiency exercises of companies like Shell.

Dr. Tim Leverton, Head of Advanced & Product Engineering at Tata Motors, focussed on the emission norms in the Indian context; and the need for new engine designs to address the same and fuel economy angles. He also indicated other sub-assemblies/concepts being looked into towards the above goals included powertrain, hybridisation, electronic architecture, etc. He said: “Driving conditions in India are very different than that in Europe and Tata is actively working with Shell to look into every aspect of current CV & PV engines, transmission, specs for new bearings, lube systems including brand new engine families to meet the emission norms”. Mr. Rick Finn, Corporate Strategy team of Infineum UK, a world leader in many of the products in its supply program spoke about his company being involved in the manufacture of additives used in lubricants and fuel; and the same playing a supportive role in contributing for the fuel efficiency exercises of companies like Shell.

Following the main speakers, there was a panel discussion moderated by Mr. Cameron Watson, General Manager, OEM & Direct Sector, Shell, and an interactive session between the audience and the panel members. Apart from the role of lubricants in contributing indirectly to the energy challenge and the choice specific to the Indian conditions, interesting points concerning the role of lube domain players in the context of new developments for mobility like electric cars were raised and discussed. Panel members opined that the initiatives are to be welcomed but they did not see any serious threat to IC engines in terms of performance and economy factors in the near future; and hence their focus would be address the fuel efficiency and emission challenges.

Ms. Mansi Madan Tripathy, CMO, Shell Lubricants, during her closing remarks mentioned that it was about the right time to collaborate for addressing the energy challenges that affect even a common man on the road; and a 360 degree approach was important.

Prof. Sundararajan T, HOD Mechanical, IIT Madras, proposed the vote of thanks bringing to an end a day of stimulating deliberations on energy challenges confronting every nation, cutting across diverse cultures, business ethos and environments.

Interview with Mr. Nitin Prasad, Country Head, Shell Lubricants India

Following the curtains down on an interesting energy challenge program, we managed to squeeze in a time slot amidst the packed schedule of Mr. Nitin Prasad, Country Head, Shell Lubricants, to get his observations on the deliberations and the role of Shell in India – read on for the excerpts from the engaging interactions:

Can you brief us about the entry of Shell into India, initial years, business metamorphosis and the journey milestones?

Shell’s connection with India started way back in late 1920s thro’ Burmah Shell for the distribution of petrol, diesel and other petro products. After the exit in mid 1970s following nationalisation of oil companies, Shell made its re-entry in 1993 collaborating with BP for the supply of lubricants and there has been no looking back since then. There are several milestones in the growth story and to pick-up a few may be a difficult task. Shell India has been manufacturing lubricants since 1997 at the state of the art lube oil blending plant at Taloja, near Mumbai. Shell is one of the most diversified international oil companies in India’s energy sector with nearly $1 billion invested in varied operations.

Tell us about your operational set-up, products for the market in general and CV sector in particular.

Shell is a major private sector supplier of crude products and chemicals to India. With over 3,000 staff in the country, Shell has a significant technology center, a financial business services center and operates an LNG receiving and re-gasification terminal. It has also a downstream business marketing fuels, lubricants and specialty products. Shell’s portfolio of lubricant brands includes Shell Helix, Shell Rimula, and Shell Spirax. Shell Lubricants India has the corporate office in Gurgaon, 6 regional offices and about 250 distributors across the country to meet the customer requirements.

For the CV sector, we have the Rimula range of products designed for CH-4 type oil and meeting the OEM requirements. What we are now seeing is CI-4 / CI-4 PLUS oil being developed in that space, to increase the wear protection up to 50-60 per cent. Rimula R4 range (CI-4 Plus oil) launched recently is being positioned for this new development and we expect customers to shift to this in future. Apart from the mineral oil lubricants, we have a full range of synthetic, semi-synthetic oil lubricants. We also have R5 and R6 (fully synthetic) and these can offer 4 to 5 per cent higher fuel economy. For these applications, we will work with large fleet operators. Semi-synthetic/synthetic oil lubricant costs when compared to the savings on the diesel front, especially with the upward spiralling prices, is going to be lower and hence we expect good market response from the discerning fleet operators.

Your observations about the oil change interval recommended, perception of the customers vis-à-vis this aspect and direct marketing initiatives.

Oil change frequency is generally guided by OEM recommendations and standard industrial practices. OEMs like Tata and Daimler are extending the range, Tata to 40,000 km and Daimler to 50,000 km. But it takes time for the message to percolate down despite OEM recommendations. Fleet owners/drivers are fairly knowledgeable and understand the strain/stress levels the oil has been subjected to in use and have devised their own ways to assess the quality; they know how much to push for and decide to change it when they feel it’s just about the right time – to get further engine and fuel benefits.

India is big country and the requirements in northeast are very different from the hilly terrain of Uttaranchal or that prevailing in southern coastal region cities like Chennai. Hence we need to have a diverse product spectrum to meet the requirements. We do have Shell managed retail outlets where oil change is done but the geographical spread requires a well-knit distribution network to meet the market needs. We approach the mechanics and workshops and educate them about the Shell brand; and have authorised the approved workshops and dealer outlets to display prominently the Shell brand – yes, at these locations, you can get the oil change done with confidence as they come with the vetting of Shell for the quality. More importantly, the mechanics and fleet operators understand the importance of Shell oil for the application and opt for it – it’s hence our task to spread the message to the customers and the dealers about the advantages of using the Shell oil over that of other brands.

Can you highlight about the market spread for your products, partnerships with OEMs and the USPs of Shell in scoring over the competition?

Shell Lubricants sells a wide variety of lubricants to meet customer needs across a range of applications. These include consumer motoring, heavy-duty transport, mining, power generation and general engineering. Shell Lubricants’ customers in India include Wartsila, Maruti Suzuki, Hyundai, M&M, Skoda, Ford and Thermax. As regards OEM association, we are working with Tata, Daimler, VECV, AMW, Putzmeister, Komatsu and Schwing Stetter to mention a few in their varied projects–both for the current and new ranges. Emission norms switch from BS4 to BS5 means completely a new approach to engine design and we see active co-operations with many more OEMs coming up.

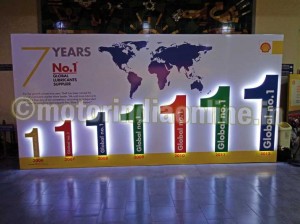

Competition for us is from other brands both from the organised and unorganised sectors. Shell has a strong legacy built over a period of time thro’ trust and reliability and we intend to continue the same. We educate the advantages of Shell products vis-à-vis competition and bring out the values to customers in terms of TOC, viz., advantages in fuel economy and lesser maintenance costs due to extension of oil drain interval and various direct/indirect benefits to engine and sub-assemblies. By our leadership in technology and research we set the bar higher for the competition to emulate and believe that it’s the only we can continue to grow in the midst of the crowded market space of the lubricants domain.

What are your plans for the future and the measures to tide over the current economy downturn?

We have recently launched new products and will continue to build the product portfolio like the Rimula R4, which is an excellent solution at this juncture considering scenario of rampant oil adulteration. We will continue to evolve semi-synthetic and synthetic oil lubricants and work with large fleet operators to show them the solutions and the benefits. The platforms and fuel mixes are changing and there is already the talk of CNG and LNG in varied applications; and we are already working with our partners for the next generation platforms. We want to spread the message and work across the value chain of OEMs, workshops, mechanics, dealers, customers, fleet owners, and drivers to provide the solutions.

Current downturn is not good for any industry with GDP growth rate languishing at 5%. We believe that this situation will not last long and it should soon be back to a robust 8%. At Shell we have worked out the business scenarios for every country up to the year 2050 and our plans are in line with the same. We are bullish about the Indian market, work towards implementing the projects and continue to address the energy challenges thro’ technology and innovation approaches.