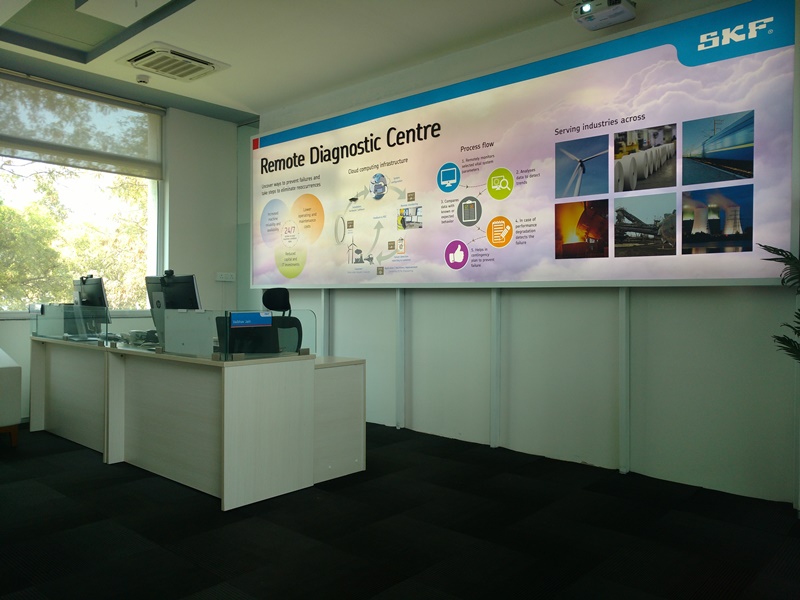

SKF India, a global supplier of bearings, seals, mechatronics, lubrication systems, and services has announced recently the inauguration of its Remote Diagnostic Centre (RDC) in India. This diagnostic centre will be located in its Pune Corporate Office. SKF’s Remote Monitoring Service makes it possible for any company with Internet access to implement a world-class predictive maintenance (PdM) program for periodic or continuous monitoring of critical machinery.

Mr. Shishir Joshipura, Managing Director and Country Head, SKF India said, “SKF is committed to service its customers and the Remote Diagnostic Center is a step forward to move closer to our customers. Moving on Industry 4.0, this will make our customers future ready and will make them capable of taking informed decisions to improve operational efficiencies of plants. RDC will help in bringing plants and remote assets together and perform better as a part of Smart Manufacturing in India”.

This SKF solution is ideal for plants with limited staff trained in predictive maintenance techniques, operations with sites located remotely from a central facility, and OEMs that desire to provide a value-added service to its customers. With hosted software and the remote monitoring services, SKF will supply the expertise, tools, and training necessary to set up a complete monitoring program anywhere in the world.

SKF knowledge enables them to apply 100 years of accumulated experience to diagnose collected data and make recommendations for actions. Customers can have global access, view reports or actual vibration data plots, 24×7 from any location. This will help customers to avoid capital investments for hardware and software, maintain data integrity, automate data uploading minimizing human error and establish consistency and standardization throughout any organization.