Stanadyne, a global fuel injection systems developer, headquartered in USA, will present new fuel systems offering a differentiated approach for the small engines to meet BS VI emissions at the Jan. 12-15 Auto Expo components show in New Delhi.

The Solenoid Controlled Unit Pump (SCUP) System was developed as a cost-effective solution for the three-wheeler applications that enables the manufacturers to meet India’s BS VI emission norms. The electronically controlled unit pump offers precise timing and fuel delivery control and is an alternative to diesel common rail technology,

The LPDMS system was developed for Tractor application & enables the manufacturers to meet India’s Trem IV – V emission norms. The system uses mechanical injectors resulting in a lower total cost of ownership (TCO).

“Stanadyne has always been committed to delivering best-in-class technology innovation for Indian vehicles. The SCUP technology stands true to our mission of taking India towards a cleaner fuel energy. Aside from addressing India’s upcoming emissions requirements, the LPDMS has the capability to serve the global market as well. We have a dedicated team of researchers and manufacturing experts who have invested time and energy in developing our state-of-the-art products to find us winning solutions” says Dr. Sanjay Chadda, Managing Director Stanadyne Near East.

Stanadyne’s LPDMS and SCUP offer alternative low-cost solutions that require fewer engine modifications compared to more complex systems like diesel common rail. The technology (SCUP & LPDMS) is designed to fit in the footprint of today’s mechanical systems, which gives them a direct advantage over the other options in the market, which would require manufacturers to make major design changes to their engines.

Showcased along with LPDMS and SCUP Systems at the Auto Expo are Stanadyne’s other Diesel and Gasoline fuel systems – Gasoline Direct Injection (GDI) pumps & injectors and Diesel Common Rail (DCR) systems. Stanadyne has been manufacturing these products in the other countries & is evaluating business opportunities for the Indian market.

Stanadyne’s GDI technology is designed primarily for 3-cylinder and above passenger-vehicle engines and is among the world’s fastest-growing fuel systems to improve gasoline fuel economy. Stanadyne developed the world’s first 200 bar GDI pump for the automotive market in 2006.

Stanadyne’s DCR technology is designed to be robust to the harshest operating conditions and low-lubricity fuels. The high-pressure pumps are available in two or four plunger configurations and sized for engines up to 16L.

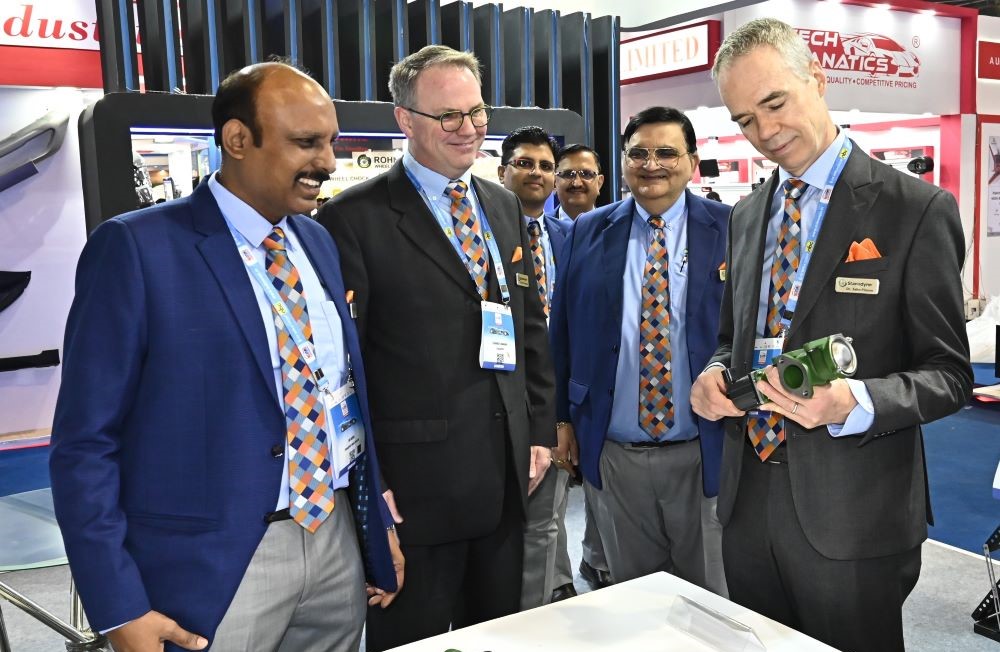

“With manufacturing facilities strategically placed across the globe, Stanadyne is committed to enabling the next generation of clean and fuel-efficient engines,” “The real near-term potential for transportation to decarbonize is in the marriage between electrical and mechanical” said Stanadyne, CEO Dr. John Pinson. “Solving the unique regional challenges faced by our customers with tailor-made products is part of our company philosophy -– the technology in our GDI, LPDMS and SCUP products is an ideal example of this.”

The carbon-reducing power of making rapid, incremental, progress through fuels and engine innovation will bring tremendous benefits. In addition, designing for remanufacturing or sustainability of the overall engine can reduce its lifecycle carbon footprint. Stanadyne is developing a new generation of high-pressure, gasoline direct-injection (GDI) fuel-injectors at 500 bar (7,252 psi) and 1,000 bar (14,504 psi) that will provide significant efficiency gains and emissions reductions. Stanadyne also introduced electric GDI fuel pumps that will enable total decoupling from the engine, optimizing fuel consumption, and reducing engine parasitic losses.

While others are necessarily redeploying resources to focus on full electrification, Stanadyne is continuing to invest in research and development to support decarbonization of the internal combustion engine. The Indian operations is nearing full capacity utilization & is looking for expanding footprint in locations nearer to our end-customer and has aggressive growth plans to achieve 3X revenue growth.