Company future-ready with clear product roadmap

Hendrickson, world leader in suspension systems for trucks, trailers and buses and other special vehicle applications, is betting big on its prospects in the Indian market. Still very much a ‘developing’ market, India presents tremendous growth opportunities for component suppliers in the commercial vehicle space, something which technology-driven companies like Hendrickson are making best use of.

In India, Hendrickson operates through its joint venture with Tata AutoComp Systems – Tata Autocomp Hendrickson Suspensions Private Ltd. (THSL) and has made significant contributions to the market’s technology evolution over the last decade. The company is witnessing great traction from OEMs and has a clear roadmap for new product introductions based on customer demand and market readiness.

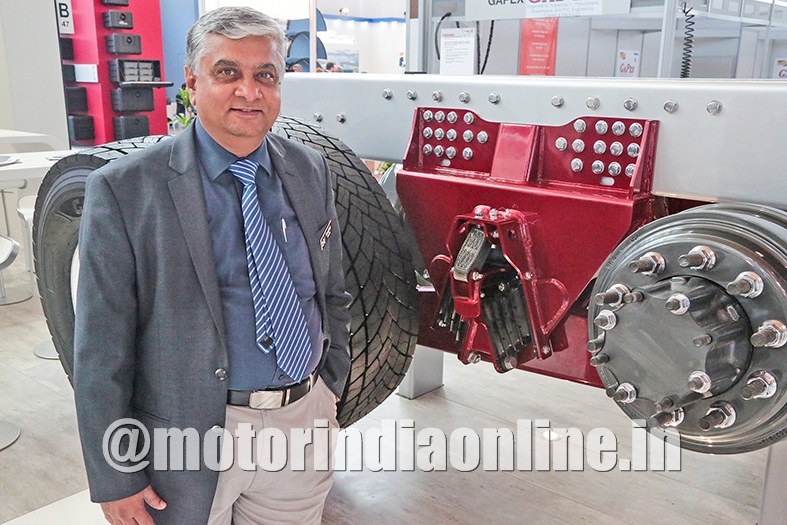

In an exclusive interview with MOTORINDIA, Mr. Sanjay Sinha, CEO, THSL, says: “India is catching up fast with developed global markets. We are seeing a technology boom and almost all the OEMs in the country are working with us. What’s interesting to note is nowadays, the focus of our discussions with OEMs is not just about our products, it is more about how we can be a technology partner in their vehicle programs. This is a very positive and encouraging sign for us and motivates us to keep coming up with the best products for the market.”

At last year’s IAA CV fair in Hanover, the Hendrickson pavilion housed six products that are currently in use in the Indian market – ‘six’ is quite an extraordinary figure, especially considering there were hardly any India-relevant products at such global tier-I pavilions around a decade back. Such has been the nature and pace of progress the Indian market has made over the last few years.

Technology, the differentiator

THSL offers suspension solutions across different vehicle segments – trucks, trailers, tippers and buses. Having proven its quality and reliability with multiple product lines, the company is looking to increase its ‘products per platform’. “We have three suspensions for trucks – parabolic at the front, lift axle in the middle and the HAULMAAX for the rear. In tippers, we have two suspensions – front parabolic and rear ULTIMAAX. We are looking at how to offer more products for a particular platform. The advantage here is our flexibility as our products can be tailored for varied ride heights and different types of axle & chassis spacing, so that the forging need not be redone. This enhances design modularity”, adds Mr. Sinha.

Whenever there’s a talk about technology, the next thing that comes to mind as a potential road block is the cost. However, cost does not seem to be a deterrent in THSL’s case, as the CEO explains: “Cost is not an issue. If we drive technology correctly, the cost automatically comes down. The end customers have started to realise that the initial purchase price is not too relevant and that the whole lifecycle cost of the product is more important. THSL is very strong in TCO which is why we have proven to be better than the rest.”

THSL has fared extremely well in the current year with its sales almost going past its business plan. “We are bullish and confident in what we are bringing to the market. The way customers are responding is also very positive. We are growing at almost double the market rate with an increase of around 25 per cent compared to last year. We are confident of continuing to do well and ending the financial year on a strong note”, he shares.

New product introductions

HAULMAAX is Hendrickson’s suspension solution for haulage applications. Over a million units of the system are running successfully around the world, a testimony to the fact that the product was largely configured keeping the developing markets in mind. As a step up to the existing product, Hendrickson has launched a 48-ton version of the ULTIMAAX for deep mining tippers which has also been designed and developed primarily for emerging markets such as India.

The latest attraction on the bus side at Hendrickson is its COMFORT AIR, serial production of which commenced in India last October for an OEM in the domestic e-bus market. “The COMFORT AIR is our solution tailor-made for electric buses. The purpose of offering it for e-buses is because e-buses require a battery space and to create the required level of balancing and stability, the market is not very comfortable with the cow horn design which is why this particular design has been made”, he reveals.

Replying to a last question on THSL’s readiness for e-mobility, Mr. Sinha says: “Our products are so well configured that whether it is e-mobility or conventional vehicles, they can be configured depending on the application.”