Tata Motors Ltd. (TML), one of the prides of the Indian automotive industry, has completed 75 years of leadership and resilience. After seven and a half decades, the company is today in a stronger position than ever, with both its divisions – the historic commercial vehicle one and the more recent passenger vehicle division – going strong and steady despite solid competition and an immensely changing and challenging market climate across both segments.

It all started in 1945 when TML’s Jamshedpur plant started manufacturing steam locomotives before foraying into truck manufacturing, bringing the global trucking technology to India nine years later. Since then, the Jamshedpur plant has been modernized and consistently equipped, particularly intensively in the last decade, with state-of-the-art equipment and assembly lines to produce a truck every five minutes.

Today, Tata Motors Group is one of the leading global automobile manufacturers with a diversified portfolio of commercial, passenger, and luxury vehicles. Part of the multi-national conglomerate, the Tata Group, the company has operations in India, the UK, South Korea, South Africa, China, Brazil, Austria and Slovakia through a strong global network of subsidiaries, associate companies and Joint Ventures (JVs), including Jaguar Land Rover in the UK and Tata Daewoo in South Korea.

‘Win Decisively in CVs’

The commercial vehicle industry witnessed major headwinds with volumes falling to the lowest over last decade, reaching the FY 10 levels. Tata Motors undertook a number of measures to navigate the downturn and ensure its readiness for quick response during subsequent recovery phase. The company prioritised strategic actions to rationalise its costs, to enhance its product performance to boost adaptability of BS-VI vehicles, to expand its product and service offerings and to strengthen its S&OP process for tighter inventory control. Its cost reduction initiatives included additional measures related direct material cost reduction, fixed cost restructuring and judicious deployment of CAPEX. Similarly to drive better realisation, it also offered a number of value-added services such as Fleet Edge (next generation connected vehicle solution) and uptime guarantee to deliver greater benefits to its customers. Tata Motors also undertook extensive ecosystem engagement actions, including channel partner engagement initiatives, extended financial tie ups, product demos to establish superiority of its BS-VI range and focussed on green-shoot microsegments. As a result, the company’s widest range of BS-VI vehicles, offering best in class TCO and profitability, was well received in the market with strong response. In parallel, it ramped up our supplies in line with the market recovery, strengthened S&OP to cater to volatile demand situation and focused on viability of the overall ecosystem. This resulted in TML being able to complete the year on a strong positive note.

Driving efficiencies

TML continues to work on optimising its input costs through sustained efficiency improvement actions across its value chain. Its cost optimisation efforts are pivoted to customer value addition, while it critically reviews each cost element for potential optimisation opportunity. As TML continues on this journey with a systematic value management approach, it remains focused to sustain the cost reduction benefits and maintain breakeven point at lower levels.

Market development

Further to its successful transition to BS-VI in FY 21, TML is continuing with its actions on new product development and infrastructure enhancement to meet the upcoming stringent Real Driving Emissions (RDE) norms. The company continues with its focus on delivering enhanced value to its customers by bringing innovative solutions and enhancing customer satisfaction. Its aim continues to go beyond mere compliance, to enhance the product performance and thus to improve the overall competitiveness. TML’s aftersales and service offerings through ‘Sampoorna Seva’ initiative continue to provide holistic support to its customers delivering enhanced productivity and earnings. Its aim is to constantly enhance our Sampoorna Seva offering through expanded scope and features.

The year gone by

TML recorded revenue from operations (including joint operations) of Rs.47,031 crores in FY 2020-21, 7.1% higher than Rs. 43,928 crores in FY 2019-20. The financial performance improved mainly due to better volumes, improved product mix, lower VME and cost savings offset partially by commodity inflation and impact of COVID-19 pandemic. The Tata Motors Group sales for the year stood at 8,37,783 vehicles, down by 12.9% as compared to FY 2019-20. Global sales of all Commercial Vehicles were 2,67,513 vehicles, while sales of Passenger Vehicles were at 5,70,270 vehicles.

Domestic market

The domestic CV industry volume experienced a drop of 21.7% in FY 2020-21, after shrinking by 30.0% in FY 2019-20. The successive drop in FY 2019-20 and FY 2020-21 is attributed to a slew of challenges that included tapering of overall economic growth, increased axle load norms, BS4 to BS-VI transition and the pandemic-induced lockdown. After hitting the bottom in H1 FY 2020-21, the CV industry demonstrated a good rebound in Q3 and Q4 FY 2020-21, led by M&HCVs and ILCVs with economy picking up gradually.

Amidst industry-wide shortage of semiconductors and steel price increase in H2 FY 2020-21, Tata Motors’ CV business managed to ramp up volumes and improve market share in H2 FY 2020-21. Overall Tata Motors CV Business sales in the domestic market for FY 2020-21, witnessed a decline of 22.6% with 2,41,668 units sold. All the four segments saw a decline in volume with the CV passenger segment being the worst hit. TML CV Business improved its Net promoter score (‘NPS’), a customer loyalty and satisfaction measurement, from a high base of 65 in FY 2019-20 to 68 in FY 2020-21.

Sales in the MHCVs category in India decreased by 22.9% to 58,528 units in FY21 compared to 75,918 units in FY20 and Tata brand vehicle sales decreased to 58,521 units in FY21, compared to 75,848 units in FY20. The MHCV segment witnessed a sharp decline in first quarter of FY21, thereby sequentially improving Q-on-Q, as the economy unlocked and infrastructure projects, housing construction and mining segment picked up. The company continued to witness strong demand in this segment and increased our market share by 70 bps to 58.1% in FY 2020-21.

Sales in the ILCVs category in India decreased by 10.1% to 37,826 units in FY 2020-21 compared to 42,077 units in FY 2019-20 and Tata brand vehicle sales decreased to 37,826 units in FY 2020-21, from 42,052 units in FY 2019-20.

Sales in SCVs & Pick Ups category in India of Tata-brand vehicles decreased by 12.2% to 1,36,835 units in FY 2020-21 from 1,55,790 units in FY 2019-20. Amongst all segments in commercial vehicles, the SCV and Pick Up category witnessed a lower decline because of increased demand from e-commerce players and necessity for last mile distribution. TML received a significant order of 6,413 Tata Ace Gold vehicles from Andhra Pradesh State Civil Supplies Corporation.

Exports

In FY 2020-21, Tata Motors exports closed at 20,283 units, 31.6% below previous year. Lockdowns imposed in all export markets to arrest the spread of COVID-19 deeply impacted the overall commercial vehicle Industry. Retails for FY 2020-21 closed at 24,105 units, a decline of 35% with respect to previous year. However the company gained market share in almost all it its major markets, including Bangladesh, Nepal, key markets of Sub Saharan Africa and Middle East region compared to the previous year.

New opportunities

TML endeavours to deliver on the continuously rising customer expectations for improved performance, better turnaround time, lower cost of ownership and refinements. It aims to leverage on the success of its connected solution “Fleet edge” and have strong a digital roadmap which will improve customers’ business. The OEM is continuing with its Research and Development activities related to advanced propulsion systems and is committed to drive actions in the areas related to alternate fuel options for the sustainable future. It is exploring solutions on alternative fuels such as Ethanol E10/E20, Bio-diesel blends, LNG, H-CNG as well as zero emission Battery Electric Vehicles and Fuel Cell Electric vehicles.

Continued success in commercial EV segment

With electrification picking up progressively in India, TML has made significant progress on developing comprehensive EV bus solution for public transport application. It currently has 350+ buses deployed on Indian roads under FAME-I and II scheme which have cumulatively covered distance of more than 10 million kms demonstrating strong performance. It has already received orders for another 500 Buses under GCC model (FAME- II). To enable faster adoption of EVs across emerging segments, it has embarked on a journey to create EV ecosystem through Tata Group synergies. Going forward, in addition to the bus segment, TML continues to engage with key customers for deployment of EVs in last mile transport application. As part of its commitment and journey towards zero emission transport solutions, it is also participating in FCEV bus tenders by leveraging its in-house capabilities and leveraging support from ecosystem partners.

Technology Absorption, Adaptation and Innovation

In the recent past Tata Motors has had significant thrust and deployed its R & D focus towards electric mobility comprising of Battery Electric Vehicles (BEVs), Hybrids and Fuel Cell Technologies. Amongst other technologies, the prototypes of fuel cell buses are under technology evaluation.

In FY 2021, the company prioritized its electric vehicles development capabilities and today its one of the frontrunners in this industry. Tata Motors developed a comprehensive approach to address the barriers and ‘Winning proactively in e-Mobility’. The Tata UniEVerse, is an entire electric mobility ecosystem—from charging infrastructure, battery cells, battery packs and electric motors, to financing options, customized for the needs of electric vehicle ownership. Tata Motors’ foray into electric vehicles would certainly reduce its greenhouse gas (GHG) emissions which mostly originate during the operational phase.

The company also launched a common Connected Vehicle Architecture through its Connected Vehicle Platform (CVP). This serves the entire portfolio across Commercial, Passenger and Electric Vehicles, to enable the extended digital eco-system for its customers. The CVP has many features which help to conserve energy and thereby has significant impact towards product sustainability. Tata Motors successfully delivered its BS-VI range of products across all segments covering diesel, gasoline and CNG fuels as per market requirements. As a proactive step towards delivering the organizational vision, Tata Motors approached BS-VI not as a hurdle, but to enhance and upgrade the entire product portfolio with technologies and features and further delight our customers by setting new benchmarks for performance, operating efficiency, comfort and safety.

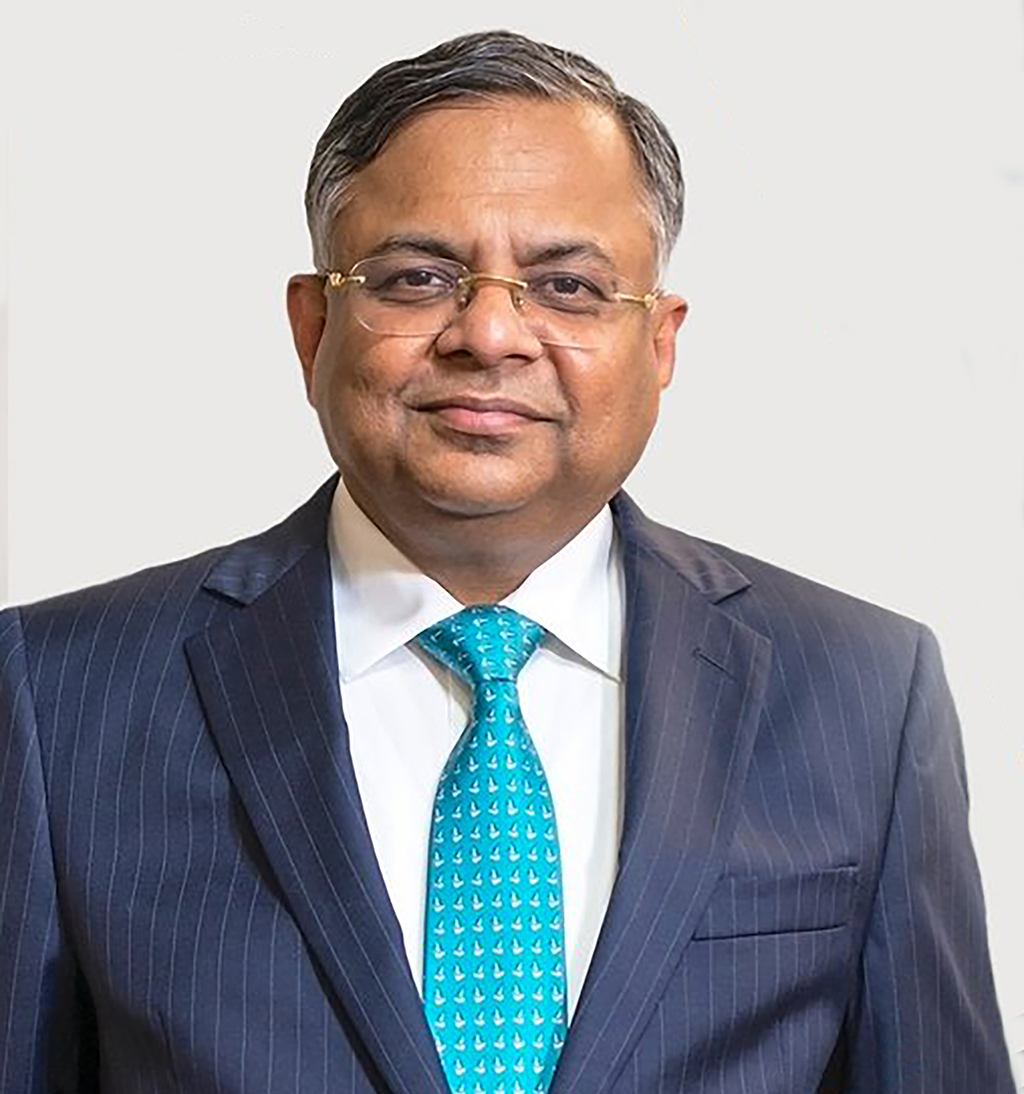

Says N. Chandrasekaran, Chairman and Non-executive Director, Tata Motors: “Tata Motors Group is in the process of pivoting its underlying business model towards sustainable mobility. In India, EV penetration in our portfolio has now doubled to 2% this year and we expect penetration to increase exponentially in the coming years. Tata Motors will lead this change in the Indian market. By 2025, Tata Motors will have 10 new BEV vehicles and as a Group we will invest proactively to set up charging infrastructure across the country. In addition, the Tata Group is actively exploring partnerships in cell and battery manufacturing in India and Europe to secure our supplies of batteries. We are also evaluating an automotive software and engineering vertical within the Group that will help us lead in a new world of connected and autonomous vehicles. We are clear that this shift to sustainable mobility is an idea whose time has come, and the Tata Group will move forward with speed and scale to seize this and proactively drive the change in consumer behaviour in India and beyond.”

In addition to the proactive measures in meeting the regulatory regime of the country, the company has been actively pursuing enhancements in fuel efficiency; leading to reduction in carbon footprint through various powertrain as well as vehicle level technology interventions.

Future Areas of Focus

The company will continue its endeavor in the research and development space to develop vehicles with reduced cost, time to market and shorter product life cycles keeping in mind the sustainability goals. Tata Motors aims for timely and successful conclusion of technology projects so as to begin their induction into mainstream products, which will lead to a promising future. With the expansion of the digital mobility landscape, the Company will keep pursuing global disruptive mega trends of CESS (C connected, E electrified, and S safe & S shared mobility).

On powertrain development front, increase in the stringency of regulations is likely to continue in future as the company move towards lower CO2 and other Engine out emissions. A slew of regulations like BS-VI with On Board Diagnostics (OBD) Phase 2, In-Use Performance Ratio (IUPR), Idle Speed Control (ISC), Real Driving Emissions (RDE), Corporate Average Fuel Efficiency (CAFÉ), Heavy and Light Duty Fuel Efficiency & Engine – Brake (to meet Endurance braking regulation) are on the cards. These regulations are the necessities to remain in business and keep us going. Apart from regulations, powertrains are also being developed with various alternative fuels such as Ethanol E10 / E20, Bio-diesel blends, LNG, H-CNG, BEV’s, Fuel cell etc. The company’s focus is going to be building technology, capability, scale & capacities in R&D to able to ride the emerging trends. The company is now focusing more on accelerated testing and validation and are using a lot of digital tools for the simulation process. Tata Motors has been able to stay ahead of the curve and create superior offerings for the customer. With keen eye for incorporating digitization, connectivity, automation and advanced regulations compliance has helped the company deliver exciting innovations to customers worldwide. With a revitalized vision set for the company, by FY 2024, the company is poised to become the most aspirational Indian auto brand, consistently winning by delivering superior financial returns, driving sustainable mobility solutions, exceeding customer expectations and creating highly engaged work force.

Future outlook

Immediate and Short-term

While there still seems to be uncertainty around the duration and the impact of COVID-19 pandemic, TML anticipates demand situation to continue to improve despite ongoing COVID-19 related lockdowns. After witnessing a decline in past two years, it is anticipated that domestic commercial vehicles industry, especially MHCV’s, will see improvement. Supply bottlenecks and commodity pressures remain key concern area in the short term. The semiconductor shortage is expected to impact the automobile industry well into 2021. An ongoing shortage in semiconductor supply is disrupting production of parts and vehicles around the world. The supply bottleneck, which is caused by a combination of factors, including the impact of the COVID-19 pandemic on production in the first half of 2020 and on manufacturing investment, is affecting a number of major carmakers and their suppliers. Semiconductor shortages are expected to improve in the second half of FY 2021-22 as new capacity comes online. As the industry continues its shift toward electric vehicles and autonomous vehicles, the importance of electronic components is increasing. The chip shortage looks set to persist for some time yet. With demand remaining high and little additional chip-making capacity expected in the short term, the shortage is expected to last into at least next year.

The COVID-19 pandemic is expected to continue to impact tourism due to social distancing measures as well as mobility restrictions. Similarly intercity travel via large intercity coach buses will also remain low. Corporates allowing work from home to its staff and similar situation is assumed for school segment, will severely impact the demand for buses.

Long-term

The automobile industry is supported by various factors such as availability of skilled labour at low cost, robust R&D centres, and low-cost steel production. The industry also provides great opportunities for investment and direct and indirect employment to skilled and unskilled labour. The Indian auto industry is expected to record strong growth in 2021-22, post recovering from effects of COVID-19 pandemic. India is expected to be the world’s third-largest automotive market in terms of volume by 2026.

The Government of India has introduced vehicle scrappage policy, under which recycling clusters may be established near ports. In scrappage policy, recycled material will be useful for the automobile industry as it will reduce cost of manufacturing cars, buses, and trucks, increasing India’s competitiveness in international markets. An incentive-based mechanism could make the scheme lucrative and encourage people to scrap their old vehicles and replace them with new ones. This scrappage policy will result in boosting demand for the automotive sector. The Indian automotive industry has welcomed this new proposal. Keeping in view the climate change commitments made by Government of India during the COP21 Summit held at Paris to reduce emission intensity by 33- 35% by 2030 from 2005 levels, it is pertinent to introduce alternative means in the transport sector which can be coupled with India’s rapid economic growth, rising urbanization, travel demand and country’s energy security. Electric mobility presents a viable alternative in addressing these challenges, when packaged with innovative pricing solutions, appropriate technology and support infrastructure and thus, has been on the radar of Government of India.

Electric mobility will also contribute to balancing energy demand, energy storage and environmental sustainability. Electric vehicles could help diversify the energy needed to move people and goods thanks to their reliance on the wide mix of primary energy sources used in power generation, greatly improving energy security. Electric vehicles would also provide major contributions to keep the world on track to meet its shared climate goals.

—

Major Milestones in Tata Motors’

75 years of CV Industry Leadership

1945

Tata Motors was founded; Jamshedpur plant starts manufacturing steam locomotives.

1954

Collaboration with Daimler Benz AG for manufacture of medium commercial vehicles

1961

50,000th vehicle rolled out from Jamshedpur facility

1965

Delivery of 1,00,000th Tata-Mercedes Benz truck

1986

Production of first indigenously designed light commercial vehicle, Tata 407

1993

JV with Cummins for manufacture of high hp and emission-friendly diesel engines

2004

Acquisition of Daewoo Commercial Vehicle Company

2005

Launch of India’s first mini-truck – Tata Ace

2009

Launch of Tata Prima, new world standard truck range

2009

Tata Marcopolo Motors’ Dharwad plant begins production

2012

Tata Motors Dharwad plant starts production of Tata Ace Zip and Tata Magic IRIS

2012

Tata Ace crosses 1 million sales mark

2013

Jamshedpur plant rolls out 2 millionth truck

2014

Tata Prima LX range launched

2014

Tata Motors brings racing to India with T1 Prima Truck Racing Championship

2014

Tata Ultra, new ILCV platform, launched

2015

Tata Ace Zip production at Dharwad crosses 1,00,000 mark

2016

Launch of Signa range of M&HCVs

2017

Launch of electric, hybrid and bio-methane buses

2018

Launch of India’s first six-axle rigid truck

2018

Installation of 1,00,000th telematic system on M&HCV trucks

2019

‘Samarth’ welfare program for CV drivers launched

2019

Launch of new SCV truck INTRA

2020

Completion of 75 years of unparalleled service to Indian commercial vehicle industry

—

Continental

Tata Motors is one of the most renowned Indian brands and is widely recognized globally. The company, over the last 75 years, has stood for its values and uncompromising quality, expanding its footprint to over 125 countries and setting a path for many to follow.

It was a glorious moment when Tata Motors was first established by Jehangir Ratanji Dadabhoy (JRD) Tata in 1945 as Tata Engineering and Locomotive Company Limited (TELCO), putting India on the map of automotive manufacturers. In its long-standing journey, Tata Motors has achieved numerous milestones, fashionably known for taking industry-defying bold steps that paved the way for many new trends and benchmarks. Making the Indian automotive industry forthcoming, exciting, and attractive for other players to enter.

In our deep-rooted association with Tata Motors, we have been part of many prestigious projects. It is a privilege for us to be part of this anniversary celebration. On behalf of the Continental family, we wish Tata Motors and its family a lovely anniversary and a successful journey ahead with many more milestones in the coming years.

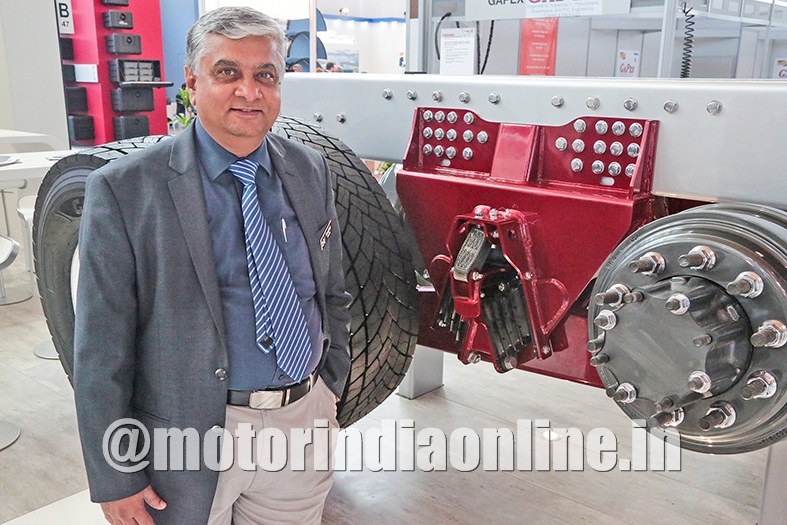

– Prashanth Doreswamy, Country Head – Continental India & Managing Director – Continental Automotive India Pvt Ltd.

Eaton

“We are very proud to congratulate Tata Motors on achieving the significant milestone of 75 years in business and making India proud on global platforms. This is a remarkable achievement, and we would like to take a moment to reflect on Tata’s legacy and the notable mark it has made on our industry.

Tata Motors has always been at the forefront of adopting and introducing new technologies, and we are grateful that we have had the privilege to partner with Tata Motors on many advanced technology demonstrations. Additionally, we are honored that our association with Tata Defense Systems is helping secure country borders. Thank you, Tata Motors for believing in us and relying on our sustainable and efficient products.

Once again, Happy 75th year, Tata Motors! May the next years be as exciting and rewarding as the first. We look forward to many more years of enduring partnership.”

– Shailendra Shukla, Managing Director, Vehicle Group, India, Eaton.

Eaton’s Vehicle Group is a strategic technology partner for customers in India and globally. With more than 110 years of experience in vehicle development, tuning and calibration, Eaton provide customers with an unrivalled combination of quality, reliability and engineering expertise.

Eaton helps create power from a variety of propulsion methods, from gasoline and diesel engines to battery-electric and fuel cells, by providing innovative solutions that improve the safety and efficiency of the next generation of passenger and commercial vehicles. Its entire product range optimizes power through smart, highly efficient, integrated solutions, making it a trusted partner for leading global vehicle manufacturers.

The company’s technology leadership is backed by dedicated Research and Development centers, and Innovation centers, in India and globally. These centers focus on enhancing its organizational capabilities by leveraging high-end engineering talent and best-in-class infrastructure. They are an integral part of Eaton’s global growth strategy and align with its commitment to organic growth and achieving global technology leadership through a focus on innovation and also region-specific customizations. Through these centers, Eaton’s technologists, engineers and designers provide strategic value creation in sustainable engineering, product development, application engineering and advanced technology through cutting-edge innovation.

Eaton’s Vehicle Group and eMobility business continues to play a significant role in shaping the e-mobility sector in India. The company also is committed to reducing the environmental footprint of our facilities in India through initiatives such as the Zero-Waste-To-Landfill and Zero Water Discharge programs, the adoption of onsite renewables and by using more connected, digital tools to prevent waste across its manufacturing ecosystem.

Tata DLT

Tata Motors Ltd was incorporated in the year 1945 with the name Tata Engineering and locomotive Co. Ltd. For manufacturing locomotives and other engineering products. They made a foray into commercial vehicles in 1954 after signing a joint venture with German auto giant Daimler-Benz.

Tata Motors is a leading global automobile manufacturing company. It has a diverse product portfolio and is one of the India’s largest OEMs offering an extensive range of integrated, smart and e-mobility solutions. They have dominated the commercial vehicle market and has had a large market share over the years.

Tata Motors had played a major role as a mentor in the formation of Tata DLT. As we all know, 15 years ago, trailer manufacturing was majorly undertaken by local unorganised players. But Tata motors came up with the idea of developing trailers as per the market requirement which would be beneficial for the transporters in terms of faster delivery and better performance.

In 2006, Tata DLT along with the Tata Motors ERC team worked rigorously on conceptualising trailers as per market requirement. For better performance of the complete heavy transportation vehicle, trailers play a vital role along with the prime mover, in ensuring transporters get better performance with respect to product life, mileage and resale value, which in turns adds up to their profitability.

Tata DLT is one of the most trusted brands in India amongst all the trailer manufacturing companies. With rich experience and promise of quality, Tata DLT has grown into becoming market leaders amongst the trailer and truck body manufacturers in India.

Established in 2005, Tata DLT commenced its operations with an aim to provide superior quality trailers to Tata Motors. Tata DLT is working with Tata Motors on various diversified business portfolio such as solid waste management products, exports, defence & special trailer market, and rigid body segment along with regular retail commercial market trailers.

Since inception, we are prime vendor for Tata Motors for the supply of trailers and truck bodies, but gradually as the demand increased in the market and following a series of successful years with Tata Motors, we have expanded our presence into the wider retail market post 2013-14. Tata Motors has still got a major share of business which is more than 75% of our total business portfolio.

We heartly congratulate Tata motors for the completion of 75 glorious years in the Indian auto industry, and also for being the market leader in the Indian commercial vehicle market and leading the way with a wide range of niche products in the passenger vehicle segment.

Such a journey has been possible only because of Tata Motors’ sheer commitment and the indomitable spirit towards work and country and we are sure this trend will go on for many more years to come.

– Rajeev Batra, CEO, Tata DLT

ZF WABCO

We take this opportunity on behalf of the ZF Group in India to congratulate Tata Motors on this momentous milestone. A flagship company of the Tata Group, the evolution of Tata Motors is synergistic with the growth of our country. We at ZF WABCO have a longstanding partnership with Tata Motors spanning a little over 5 decades, starting whilst the company was still Sundaram Clayton and this partnership has grown stronger over the years. ZF WABCO continues to strengthen its technology partnership with Tata Motors and has co-created pioneering technologies for the CV segment in India including ABS, Electronic Stability Control, AMT, Hill Start Aid, Automatic Traction Control and the industry first Advanced Driver Assistance Systems. Anchored in ZF‘s vision for Next Generation Mobility built on the principals of Zero Accidents, Zero Emissions this technological partnership with Tata Motors continues to support the Government of India’s Vision Zero initiative and to position themselves as a market leader in safety and efficiency, thus making them a preferred choice for fleets. As we continue together on this journey of growth, I on behalf of my team once again wish the leadership and the teams at Tata Motors, a long and successful growth journey and an enduring partnership with ZF WABCO.

– P Kaniappan, Managing Director, WABCO India

Jamna Auto Industries

We at Jamna Auto Industries (JAI) congratulate Tata Motors on completing landmark milestone of 75 years. JAI has been proudly associated with TML for the last 35 years. TML is one of our largest customers of suspension products.

JAI ‘s journey with TML has been a great learning curve for both the companies. TML was the first company in India to introduce parabolic springs technology developed by JAI in HCVs. JAI’s R&D team works very closely with the ERC team at TML to improve the durability of products by introducing new process and product technologies.

We wish TML all the best and look forward to an ever-lasting association with learnings and mutual growth in new technologies.

– Sunil Laroiya, President, Jamna Auto Industries

NPL BlueSky Automotive

NPL BlueSky Automotive Pvt Ltd is proud to partner with an industry leader that shares our vision of commitment to quality, reliability and transparent communication

– Nandan Agrawaal, Managing Director, NPL BlueSky Automotive Pvt Ltd

Being Associated with Tata Motors as a Business Partner is a richly rewarding experience. They have always been extremely supportive of the various developmental initiative taken by us as an industry leader. Congratulations to the entire team on this wonderful accomplishment of 75 glorious years.

– M D Kumar, Vice President, NPL BlueSky Automotive Pvt Ltd

Jasper Industries

We are immensely proud of the accomplishments of Tata Motors over the last 75 years and are honoured to be their channel partners for more than six decades. Our long association with Tata Motors has improved the lives of entire communities of dealers, customers and other stakeholders for generations. We are eternally grateful and steadfast in our support for the success of Tata Motors.

– Sumanth Badiga, Managing Director, Jasper Industries

Hexagon – MSC

Over Tata Motors’ illustrious history of 75 years, the company has always been a pioneer at many levels. Hexagon | MSC is honored to be a trusted partner to the company in its 75-year journey. Tata Motors has been a driving force for continuous innovation and nation-building directly or indirectly. The company is undoubtedly one of the early movers investing in simulation technology about two decades ago in India. For some background, Tata Motors used simulation technologies from Hexagon | MSC to help constantly improve various aspects of vehicle design across its platforms and over the past decades. The Hexagon Group has had the good fortune of working closely with Tata Motors over the years across research and development, production, quality, and inspection technologies. Our collaboration has undoubtedly deepened, and we hope to continue to grow this association in the future.

The excellent team at Tata Motors has continuously worked to innovate and stay at the cutting-edge of technology and build genuinely world-class products. The company has and will play a key role in redefining the future of automotive in India. I wish the Tata Motors team the very best for the future.

– Sridhar Dharmarajan, EVP & MD, Manufacturing Intelligence division, Hexagon & MSC Software Indo Pacific

ELVI India

Year 2021 is a milestone year for Tata Motors. On one hand they are completing 75 years of their existence and this joy is doubled with the acquisition of their own, India’s first airlines, Air India. What a glorious moment!

On this blissful occasion of Platinum Jubilee Celebration of Tata Motors, ELVI India extends our warm greetings to the leading global automobile giant, who has time and again stood with the nation and helped in building it stronger. Cheers to future achievements and past glories.

Wishing Tata Motors many more years of success and innovation!

– Shivam Sawhney, Sr. General Manager, ELVI Bardahl India

Tata Autocomp Hendrickson Suspensions

It gives me immense pleasure to participate in the 75 years celebration of Tata Motors. TML is the pioneer of the Indian commercial vehicle industry and has played the role of game-changer by launching many first-of-its-kind vehicles. Tata Hendrickson is proud to be associated with few of such firsts in the industry starting with single tyre lift axle suspension system for 4-axle truck 15 years ago, subsequently added lift axle in 5-axle trucks and dual tyre lift axle in 6-axle trucking. Recently, in the last three years, TML has introduced another industry first, Tata Hendrickson’s advance rubber-metal suspension ULTIMAAX with no-grease, minimal maintenance, highly durable suspension for tippers with 4,000 hour / 4 years warranty. TML has given us an opportunity to develop light-weight air suspension COMFORT AIR for electric buses, which has been highly appreciated by end-customers for its performance and ride comfort. I, on behalf of Tata Hendrickson family, wish that TML launches many more innovative and industry-first vehicles in the near future.

– Sanjay Sinha, CEO, Tata Autocomp Hendrickson Suspensions

BorgWarner

Congratulations Tata Motors! A company’s 75 years anniversary has to be celebrated. We at BorgWarner wish you many successful years to come. We are proud to have worked alongside Tata Motors as a business partner for all powertrain solutions in diverse vehicle applications for more than a decade now. It has been an exciting experience for us to collaborate on the journey from BS-IV to now BS-VI. We look forward to also supporting your electrification business in the future to get closer to our vision of a clean and energy efficient world. Thank you for your trust in BorgWarner.

Arteco Coolants

We extend our heartiest congratulations to Tata Motors for completing 75 years of excellence and setting an exemplary standard in the industry.

Arteco commends you for reaching this milestone and we wish you a bright future and tremendous growth as you continue to inspire us with your endeavours.

– Manish Mehra, Managing Director, Arteco Coolants India Pvt. Ltd.