Currently the Indian economy is growing fast, fuelled by development in infrastructure, new cities, flyovers, airports, roads connecting cities and villages, etc., which require transportation with efficient materials handling in construction. Cement being one of the basic elements for setting up strong and healthy infrastructure, it plays a crucial role in the economic development of the country. Tata Motors, as part of its wide range of applications, offers ready-to-use bulkers to provide efficient solutions to both inbound as well as outbound logistics for the cement industry.

The industry is gradually experiencing a shift from bagged cement movement to bulk cement movement. There are several factors which are pushing the manufacturers as well as consumers to shift from bagged to bulk cement movement. Issues related to efficiency, safety, storage and operating cost are driving the shift from bagged cement movement to bulk transportation.

Tata Motors is offering ready-to-use bulkers which provide safe, economic and environment-friendly loading, unloading and material transportation in the Indian market. Movement of material via Tata bulkers ensure pollution-free healthy environment at the workplace. Though the use of bulkers is still in its infancy in the Indian market, the response to Tata bulkers is a good indication of the growing acceptance of the application.

The ready-to-use bulkers offer intrinsic benefits to customers such as providing them a one-stop shop solution from the Tata stable, eliminating the need for a separate chassis supplier and body builder. A factory-finished product with very high quality standard is guaranteed with Tata Bulkers.

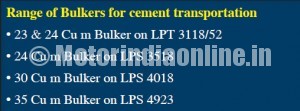

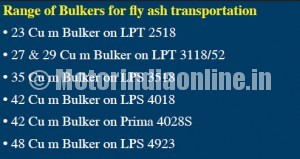

The company offers bulkers for both cement and fly ash movement. It has a range of products from 23 cum to 48 cum on LPT 2518 and LPS 4923 chassis.

There are several unique features in the offering as listed below:

• Aeration pad: All the company bulker ranges are provided with high quality imported aeration pad from Germany. This helps in discharging the material from the pressure tank. These high quality aeration pads ensure the minimum residue left inside the pressure tank (less than 50 kg) as compared to the locally made bulkers (more than 500 kg residue), thereby ensuring higher payload after every trip.

• Variable thickness: The pressure tank has been designed keeping both quality and economics in mind. Tata bulker’s pressure tanks offer the best combination of quality and best possible payload at the same time. This is ensured by using variable thickness of steel sheets in different sections of the tank as per the pressure application.The bulkers are made with the best grade of steel that ensures the lowest maintenance.

• Seamless steel tubing: Tata bulkers come with the seamless steel tubing which ensures the highest level of strength and with no obstruction and sticking of particles to the tube unlike the local vehicles which use welded tubes to achieve the desired length causing obstruction in the welding areas because of uneven surface and welding burrs

Safety comes first at Tata Motors. These bulkers are built with German quality imported parts with highest safety standards. Safety features are specially designed keeping workers’ safety in mind. Thorough engineering calculations are done in each and every case.

Manufacturing excellence

Tata bulkers have set very high standards in terms of product quality, technology, operational/environmental safety and strong after-service which is far more difficult to match with by the conventional bulkers’ provider. Tata enjoys a strong history of making much optimized and technologically acclaimed product around the globe.

• Uses special high grade steel to ensure the best possible strength to the pressure tank. It also ensures best durability and long life of the bulker

• Use of different thickness sheets in pressure tank ensures maximum strength and maximum payload.

• 100% replicable welding quality ensures constant quality and safety

• Imported German quality aeration pad which aids in material discharging and minimal residue left inside the tank which does not need any maintenance unlike local offerings

• High quality paint standards and process is followed to ensure the best quality paint to prevent the vehicle from rusting and corrosion

• Seamless tubing for air and material flow ensures maximum strength of the tube as it is a single tube and also minimum restriction to the material flow. This reduces chances of corrosion inside the tubing

• High quality safety valve, non-return valve, air pressure gauges and air vent valvesprovide for safe operation

In the cement industry, operational hazards are tremendous due to the harmful effects of cement and flyash if they are inhaled.

Many onsite projects like highway construction and infrastructure developments are rapidly booming, and maintaining a storage space at worksite is a difficult and unsafe practice. Maintaining cement bags at worksite not only results in degradation of cement quality but also involves high risk of adulteration and theft of cement.

In India currently only less than fifteen per cent of cement is moved in bulk as against 80 per cent in developed countries. There is a huge potential for bulker as a safe and environment-friendly solution to the producers as well as users. Tata Motors’ range of ready-to-use bulkers could possibly drive the growth of bulk transportation in the country.

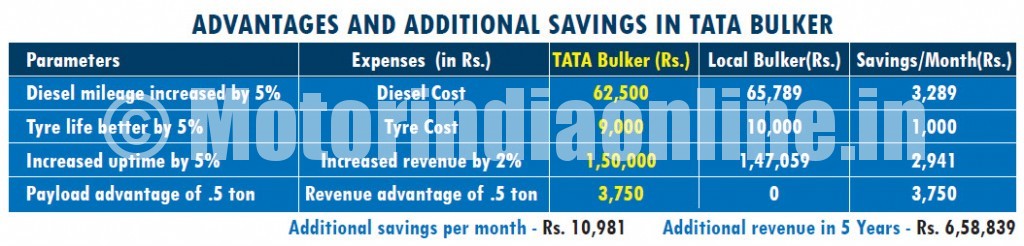

Advantages and additional savings in Tata bulker:

• Tata Bulkers offera payload advantage of 500 kgwhen compared to locally made bulkers which in turns lead to more revenue generation.

• Low maintenance of Tata bulkers provides more uptime to the customer and hence helps in getting approximatelythree per cent more revenue.

• The excellence in manufacturing provides even load distribution and provides five per cent better tyrelife when compared to other bulkers.

• The Tata bulker range ensures minimum residue left after operation, hence providing better payload.