Sriram Muralidharan, Director of Telma India, spoke exclusively with Rajesh Rajgor about the company’s emission-free braking systems and provided an update on its operations in Europe and India

Presence at IAA 2022

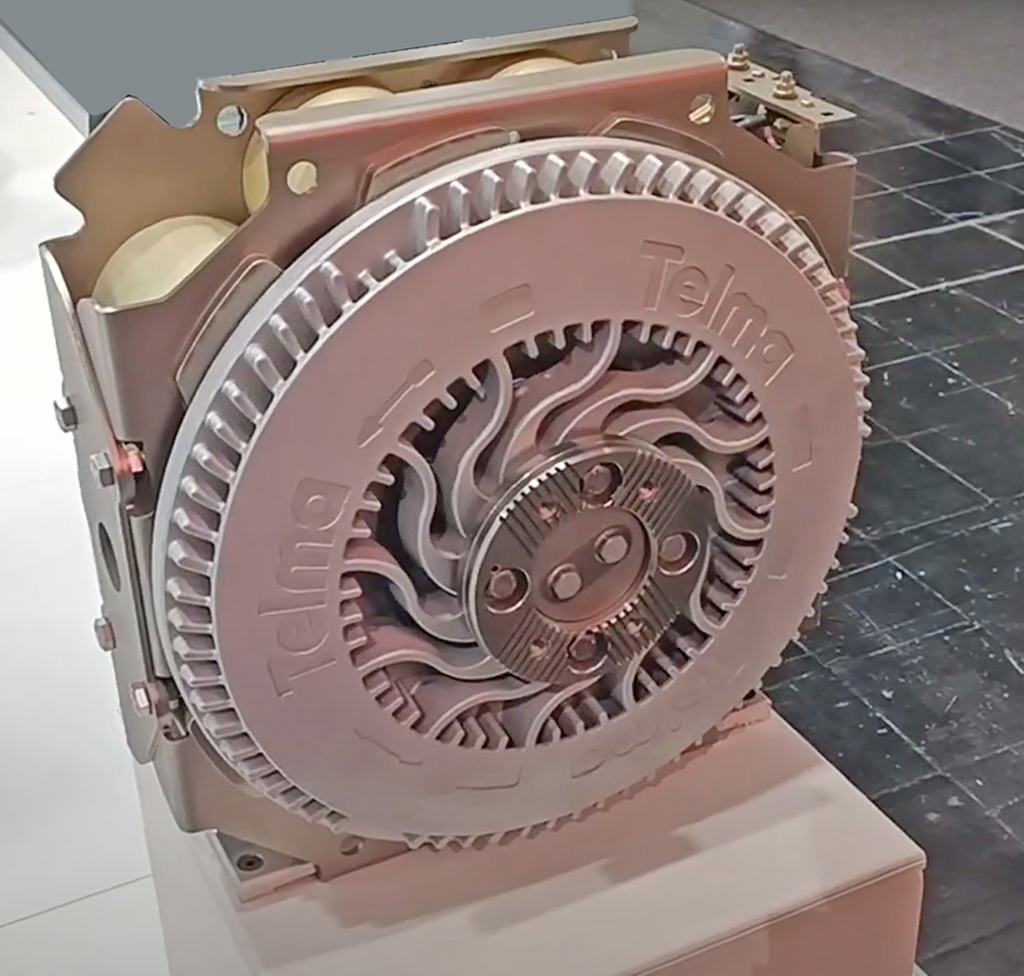

We are showcasing regenerative braking, which is how OEMs refer to the electricity produced by a retarder, along with hybrid induction brakes. We have a hybrid retarder that is well along in development. All hybrid retarders will be deployed during the course of next two years. Everything has been taken care of in terms of weight loss and current consumption. Our range is the widest, starting at 350 Nm and going all the way to 3,200 Nm. Here, we are displaying the Telma product line as well as the technological advancements that we have made in the areas of weight reduction and electric consumption.

For more than 75 years, we have created frictionless braking systems based on the electromagnetic induction theory. These brake systems reduce wear on service braking systems, increase braking durability and produce no fine particles since they absorb a major portion of the braking energy, which also lowers maintenance costs. Looking ahead, the business claims it is continually looking for solutions to satisfy the rising demands brought on by both existing and potential environmental challenges. As a result, it has now constructed a completely new system, the HIB (hybrid induction brake).

All vehicles over 5 tonnes that employ a combustion engine, a hybrid driveline, or are powered entirely by electricity or hydrogen can use this comprehensive hybrid solution. The system is self-powered and capable of providing the propulsion, braking and electrical power requirements for the vehicle. In addition to acting as a retarder, the system has two other functions: an electric motor function that provides power support for combustion engines and a generator function that transforms braking energy into electrical power for the auxiliary systems of the vehicle, like the air-conditioning.

Business in Europe

Telma managed to maintain its market share even during the pandemic in a unique way and we were able to maintain accurate financial records. In Europe, we operate 10,000 retarders and the pandemic era had little of an effect. In other places, we have exclusive rights, and fortunately, that market has endured through time. So, we never had such pandemic impact casualty. As we continue to advance, we see numerous other European market areas where Telma has increasing potential.

Acceptance in Indian Market

I would say that the Indian market has been stagnating for a long time now in terms of effective implementation of endurance braking regulations. The effective knowledge about the effects of ‘auxiliary braking systems’ first emerged around 2004–2005 and we supplied our initial 400 Nos. retarders through Volvo Mark I buses and later with Ashok Leyland ‘Luxura’ rear engine coaches. Today we are single source to DICV for all its 16T/18.2T Intercity Buses. However, to note that over a period of last 15 years’ time, the average volume of numbers we have been viewing has only been 3,000. We hope that ‘Type II a’ regulation and its implementation effective 1st April 2022 will bring more volumes to Telma. Therefore, we began operating the manufacturing factory in Chennai. At first, we started assembling all imported CKD components in India. We will localise up to 50% of crucial components during Y2023.

8×2/10×2 heavy duty Hazardous goods trucks, 44T/54T Tractor-Trailers, all Tourists and Intercity coaches will demand use of retarders to pass endurance braking requirements and therefore we are seeing a lot of opportunity in these segments. We are looking at TIV of 10,000 retarders annually and expected to grow at 30% YoY. We are optimistic that Telma will play a major role in transforming and shaping braking regulations in India.

Our products are best suited for Indian sub-continent conditions due to instant braking at low average speeds, air-cooled and not oil-cooled, flexibility of fitment, ease of maintenance, simplicity, so on. Our products’ ability to be retrofitted is a unique feature, but we advise OEMs to adopt it sooner so that it can be a fleet operator’s cost-effective solution. Today private fleets may find that their preferred features are not offered by OEMs and must turn to us for fitment. This version is more expensive because we must make numerous modifications to a vehicle before retrofitting.

Telma’s USPs

First, the frictionless braking is referred to as Telma, making it a futuristic example particularly keeping in mind the climate change. All bus fleets have experienced cost-savings. Therefore, operating a Telma retarder is nothing new for any fleet operator. When the fleets start using the retarder, they won’t choose a vehicle without a retarder. Therefore, a motorist who has driven a vehicle with a retarder will undoubtedly choose a vehicle with one. Therefore, any driver, such as a bus driver or a fleet operator, is not unfamiliar with the term retarder and knows the advantages of Telma.

We further offer cost-savings in terms of lining savings, cost savings for driver’s comfort, fewer accidents and more safety. For instance, if you go to China or, more or less, anywhere in Europe, it is a requirement in the school buses, Ambulances. Therefore, safety is one role that has been recognised by Indian bus operators. There are so many different functions. The first is liner saving, which reduces breaks. Especially with Telma, which uses a straightforward technology, all of the possibilities are available.