Automobiles is one of the priority sectors for the Thai Government, which is expected to grow by 10 per cent this year, thanks to the country’s focus on exports.

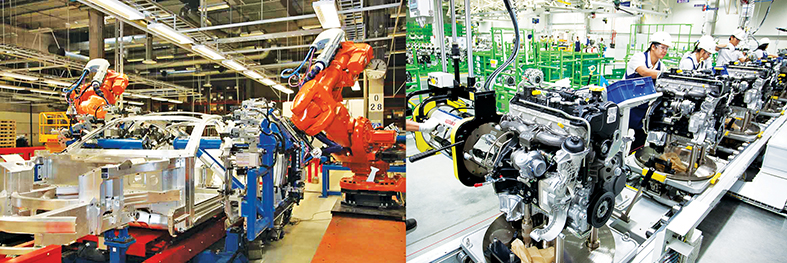

Thailand’s automotive industry has been steadily developing for over 50 years with strong support from both the public and private sectors. The Kingdom is the largest automotive producer among South-East Asian countries. Considered one of the top automotive producers in the world, it has now emerged ASEAN’s leading automotive hub, accounting for approximately 12 per cent of the country’s gross domestic product (GDP).

In 2014, the Thai automotive industry was the largest export sector with exchange earnings worth $30 billion. With 2.46 million vehicles produced in the country in 2013 offering employment to over 550,000 people, Thailand was ranked the nineth among the automotive manufacturers in the world. Even though affected by the economic slowdown in 2014, the sector is expected to bounce back in 2015 and attain a production level of three million units. In order to develop Thailand as a global green automotive production base and promote automotive technology research and development, the Government formulated the Master Plan for Automotive Industry (2012-2016) in co-ordination with the private sector.

Major car manufacturers in the country have applied for the second phase of the Thailand Board for Investment’s eco-car program. Companies signed up for the new phase include Ford Motor Company, Mazda, Volkswagen and, most recently, General Motors. These projects will add up to $4.3 billion investment to produce around 1.58 million vehicles. This second phase is part of the Thai Government plan to boost overall annual car production to three million units while strengthening the ASEAN as a major hub for automotive manufacturing. The supporting industries will also benefit from the eco-program, especially auto parts outsourcing in Thailand. Automakers are expected to use many locally produced components in vehicle manufacturing.

It is against this backdrop that Intermach – Subcon Thailand 2015 was organized by UBM Asia (Thailand) Co. Ltd., with the support of the Thailand Board of Investment, Thai Subcon, Thailand Convention and Exhibition Bureau (TCEB) and Sheet Metal Asia 2015 during May 13-16. The show was considered ASEAN’s largest International Industrial Machinery and Subcontracting Exhibition.

Inaugurating the exhibition, Mr. Chakramon Phasukhavanich, Thailand Minister of Industry, said the Government and private sectors have joined forces to put Thai Entrepreneurs’ Competitiveness on a par with International Standards. The show has become ASEAN’s largest International Industrial Machinery and Subcontracting Exhibition, and Thailand is set to becoming a high-skill manufacturing hub. Entrepreneurs should prepare for the manufacture of industrial parts, particularly for the emerging industries of aerospace and medical devices.

According to the Minister, ASEAN countries are transforming themselves into one single market with a population of over 600 million. The region will definitely become one of the world’s most important trade groups in the very near future.

Mr. Manu Leopairote, Chairman of UBM Asia (Thailand) Co. Ltd., noted that the exhibition goal was to help boost industrial entrepreneurs’ competitiveness by presenting manufacturing/subcontracting technologies and business-matching opportunities in a modern, action-oriented environment.

He also said: “By holding Intermach and Subcon Thailand at the same time and at the same venue, we offer the most comprehensive show for industrial entrepreneurs in Thailand. We have created an unbeatable stage for them and parts manufacturers will enjoy the best business opportunities and connect with buyers from around the world. This will also increase the demand for manufacturing technology and machinery.”

Intermach and Subcon featured more than 1,200 exhibitors from 40 countries from around the world. They came with state-of-the-art technology and machinery. Indeed, over 150 new products were displayed for the first time. Five of Japan’s top machinery manufacturers – Mazak, Mitsubishi, Okuma, Sodick and Toyoda – had their booths running in the “Top Japanese Makers Zone”.

The well-prepared exhibition met almost all needs of the entrepreneurs since it was held at the start of the buying cycle. This ensured that buyers who placed orders would get their equipment before the year end.

Mrs. Hirunya Suchinai, Acting Secretary General of Thailand Board of Investment, noted that BOI organized Subcon Thailand in collaboration with UBM Asia and Thai Subcontracting Promotion Association for nine consecutive years. The current year event provided parts manufacturers with the opportunity to meet with more than 20,000 world-class parts buyers from as many as 15 countries.

A top destination for automobiles

A recent visit by MOTORINDIA Managing Editor & Publisher R. Natarajan to Thailand arranged by the Royal Thai Consulate-General, Chennai, and Thai Airways International Chennai Office, to broaden the economic relationship between Thailand and India, was of special significance. During the visit, he was able to observe that Thailand offers immense potential and has emerged a top destination for the automobile and auto component producers. The visit included a drive to the factory of Honda, the headquarters of Tata Motors (Thailand) Ltd., the manufacturing facilities of Thai Auto Tools and Die Co. Ltd., Rojana Industrial Park, etc. Almost all the company executives acknowledged their presence in Thailand and the Government’s utmost co-operation for promoting their products very effectively not only in the domestic market but also at the global level.

Honda’s commitment to Thailand

According to Mr. Pirapat Kanoknark, General Manager of Honda Automobile (Thailand) Co. Ltd., despite natural calamities such as floods faced by the country, his company has been able to bounce back not only for normal production but also restore the confidence of its customers. In fact, the manufacturing plant located at Ayutthaya, Thailand, was closed for six months due to floods, and it was reset in a record time by installing machines.

With a high level of customer confidence in its world class products, Honda is now setting up its second plant in the Rojana Industrial Park, and production is expected to commence soon. With a capacity of three lakh units, Honda currently produces a wide range of cars and SUVs. The engine plant located in Thailand is also the fourth largest for Honda Motor Company, after Japan, the US and China. Honda is also fully committed to CO2 emission standards.

Investor-friendly approach behind Tata entry

TAT’s OEM drive

Thai Auto Tools Group (TAT) consists of several companies producing auto components mainly for OEMs like Toyota, Honda, Mitsubishi, Ford, etc.

Mr. Banthun Laosinchai, Managing Director, Thai Auto Tools and Die Co. Ltd., revealed that his company’s products have been well received among OEMs due to quality maintenance both during production and processing. The group has also ambitious plans to expand its product portfolio.

Rojana – one-stop service provider

MOTORINDIA could also learn that Rojana Industrial Park Public Co. Ltd., established in 1988, has become a one-stop service provider accommodating over 230 industrial houses. Already many automobile companies, including Honda, Federal Mogul, Sandan and Nippon Steel, have set up their facilities at various locations, thanks to the excellent infrastructure facilities related to road, power, water, etc. In fact, Rojana has established a dedicated power plant to meet the full requirements of customers within the park. The aggressive management team of Rojana is also well geared to assist and provide able guidance to investors.

While going around the plant, it was also observed that Rojana promoters lay maximum emphasis on greener environment.

By R. Natarajan, Managing Editor & Publisher and Ganapathy Sankaran Mohan, Editorial Team