At a Technology Road Show on January 23, Mr. Ajay Tandon, Managing Director & CEO, Tata AutoComp Systems Ltd., and Mr. Arvind Goel, President and COO, Tata AutoComp Systems Ltd., handed over the keys of Tata 4928S to Mr. Ravi T G, Vice President, SICGIL Industrial Gases Ltd. This vehicle was retro-fitted with Tata AutoComp Hendrickson Syspensions’ (THSL) HUV suspension for the tandem drive axle system.

SICGIL India Ltd., incorporated in 1947, is the largest manufacturer and distributor of liquid CO2 and dry ice in the country. The company has strong manufacturing and distribution network across the country with a fleet strength of 100 to meet the client requirements. It is the only public limited company exclusively in the CO2 business. It offers high purity liquid CO2 of 99.99 per cent (International Grade for Food CO2) and services to all industrial users covering soft drinks, precision welding and foundries. It is also associated with distribution of dry ice blasting equipment.

SICGIL was looking for solutions to light-weight the Tata 4928S tractor that hauls the 28kl CO2 tank-trailer with the objective of improving its utilization. It has proactively engineered internal programs to improve driver efficiency and productivity through various motivational and technical inputs. Gas as a product to be transported carries the risk of evaporation. Hence the need for a robust and durable product.

SICGIL summarized its need for light-weighting the vehicle load to increase the pay-load as well as revenue and to improve the up-time through less maintenance and vehicle breakdown, improve the driver’s ride comfort, thus gaining higher output, and improve the tire wear.

A team from SICGIL approached THSL for an innovative solution to meet the above needs. They worked together and zeroed in on HUV, an advanced rubber suspension system designed for tandem drive axle system. THSL already did a study on mining, construction and haulage sectors to customize HUV to suit Indian operating and maintenance conditions. The added features made this more robust and durable.

The Tata Tipper LPK 2523 on which THSL retrofitted the HUV was then subjected to field trials in mining areas for over a year. The result: smooth operations without any maintenance or break-down. This tipper has already completed more than 2,000 hours of field usage without any tyre change. The tyres still look good to go for many more hours.

“This system has provided SICGIL an additional payload of 350 kg and looking for further on increasing payload and cost-driven efficiency with innovative technology on transportation”, Mr. Ravi said.

Speaking on the occasion, Mr. Ajay Tandon said: “At Tata AutoComp, we are committed to design cost-efficient solutions with appropriate technology that is suited to the tough Indian conditions. This solution created by THSL is an example of our commitment.”

Mr. Arvind Goel observed: “THSL has been a game changer in Indian CV space when it comes to suspension systems. Success of Paralift Suspension system in Tata 3118 is an example for this. I am sure that this metal rubber suspension family would be another game changer.”

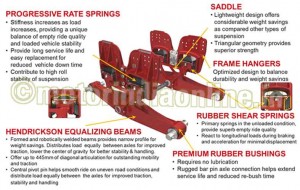

Unlike the conventional bell-crank system with leaf-spring wherein many moving parts need regular lubrication and maintenance, HUV has no leaf spring or any other such regular wear & tear elements. This avoids down-time towards greasing many points or repair of broken leaves. Carefully designed suspension provides optimum ride quality even in unladen condition, thus protecting the body from road vibrations. This improves return trip time. Time thus saved through reduced downtime and faster return trips can be used to make more revenue earning trips, especially while on short hauls in mining application.

Hendrickson, the world leader in advanced design suspension solution for commercial vehicles, introduced its walking beam suspensions way back in 1926. Since then, the company introduced many variants across applications and world geographies.

Hendrickson, the world leader in advanced design suspension solution for commercial vehicles, introduced its walking beam suspensions way back in 1926. Since then, the company introduced many variants across applications and world geographies.

The newly introduced RT, HN and Haulmaax series are now popular in the US, South America, Europe, Australia, New Zealand, Japan and China. These systems, configured for tandem axle systems, are used on trucks, tippers and tractor-trailers in 6×2, 6×4, 8×2, 8×4 and 10×2 vehicle configurations and across sectors like mining and construction.

It was only after a thorough application study and understanding of the user behavior in the Asian market, especially in India and China, that Hendrickson innovated the 4th generation advanced rubber suspension HUV. Hendrickson introduced this in China and sold over 10,000 suspensions in a short span of time.