When Raj Path Infracon (P) Ltd. created a Limca Book of World Records for laying 39.69 km of road in a single day, ULTIMAAX® from Tata Autocomp Hendrickson Suspensions Ltd. (THSL) was a major contributor, proving once again that it is the ultimate choice for tippers, reports Rajesh Rajgor

On the occasion of Maharashtra’s 61st anniversary, Raj Path Infracon (P) Limited (RPIPL), a Pune-based reputed infrastructure and construction company, in collaboration with the Public Works Department (PWD) laid a 39.69 km road between Pusegaon and Mhasurne in Satara in just 24 hours. It was indeed a unique feat in this sector. Sharing more details of how it was done, Jagdish Kadam, Chairman and Managing Director, RPIPL, says, “When we got this contract from PWD to work on the 47 km road from Pusegaon to Mhasurne under the hybrid annuity model (HAM), we found that the previous single day record in road construction was for 25.54 km. That spurred us to break this record.”

“It was also an opportunity to put our efficiency and capabilities to test. We have been using Tata tippers with ULTIMAAX® suspension fitted to it for three years now and I am thrilled to share that not a single tipper faced a breakdown. Collectively with many other stakeholders we set the world record by laying 39.69 km of asphalt i.e., bituminous concrete road in one day. This world record is dedicated to the state’s people as it coincided with Maharashtra’s 61st anniversary,” he adds. The road is 3.5 metres wide and 39.69 km long, connecting Pusegaon, Jaigaon, Aundh, Gopuj and Mhasurne. “The project was completed with a team of 474 workers and 250 vehicles and machinery,” Kadam informs.

“The initiative was carried out in accordance with the guidelines established by the federal and state governments in view of the pandemic,” he adds. The company has been able to achieve near impossible feats even in the past, notable of which are the Manav irrigation project in 1998 which was completed in four months against the given timeframe of two years. Similarly, timely completion of the Rauri Dam project in Ahmednagar got them appreciation from the World Bank. “Former President Pratibha Patil, taking cognizance of our work, had invited us to the Rashtrapati Bhavan in 2010, which was the high point of my career,” Kadam says. RPIPL has been engaged in the infrastructure business for over 30 years.

In fact, it is one of the leading players in road construction, employing over 2,500 people. The company has in its stable an enviable fleet that helps them set difficult construction and infrastructure projects. “We have a fleet of 613 vehicles, including water tankers, concrete paver machines, bitumen pavers, excavators, soil compactors and 180 Tata tippers out of which 110 tippers are fitted with ULTIMAAX® suspension. We have achieved fantastic results in terms of driver comfort and top-notch service from Tata Autocomp Hendrickson Suspension, leading to reduced maintenance time and superior durability. This helps to achieve more trips and higher uptime,” Kadam shares.

Value-Addition with ULTIMAAX®

It is not a secret any more that the ULTIMAAX® suspension has added specific value in the tippers that RPIPL has been using. As Kadam puts it, “If a suspension breaks it leads to cost in maintenance and substantial downtime. Moreover, since we work in the remote interiors, we need a robust solution that is sturdy enough to bear the tough operating conditions. The ULTIMAAX® not only manages weight but it also improves ride quality, safety and durability. The new technology provided by THSL through ULTIMAAX® suspension is convenient for the tipper drivers and provide the much-needed comfort. ULTIMAAX® has played a significant role in us achieving the certificate of excellence in various projects in a very short span of time.”

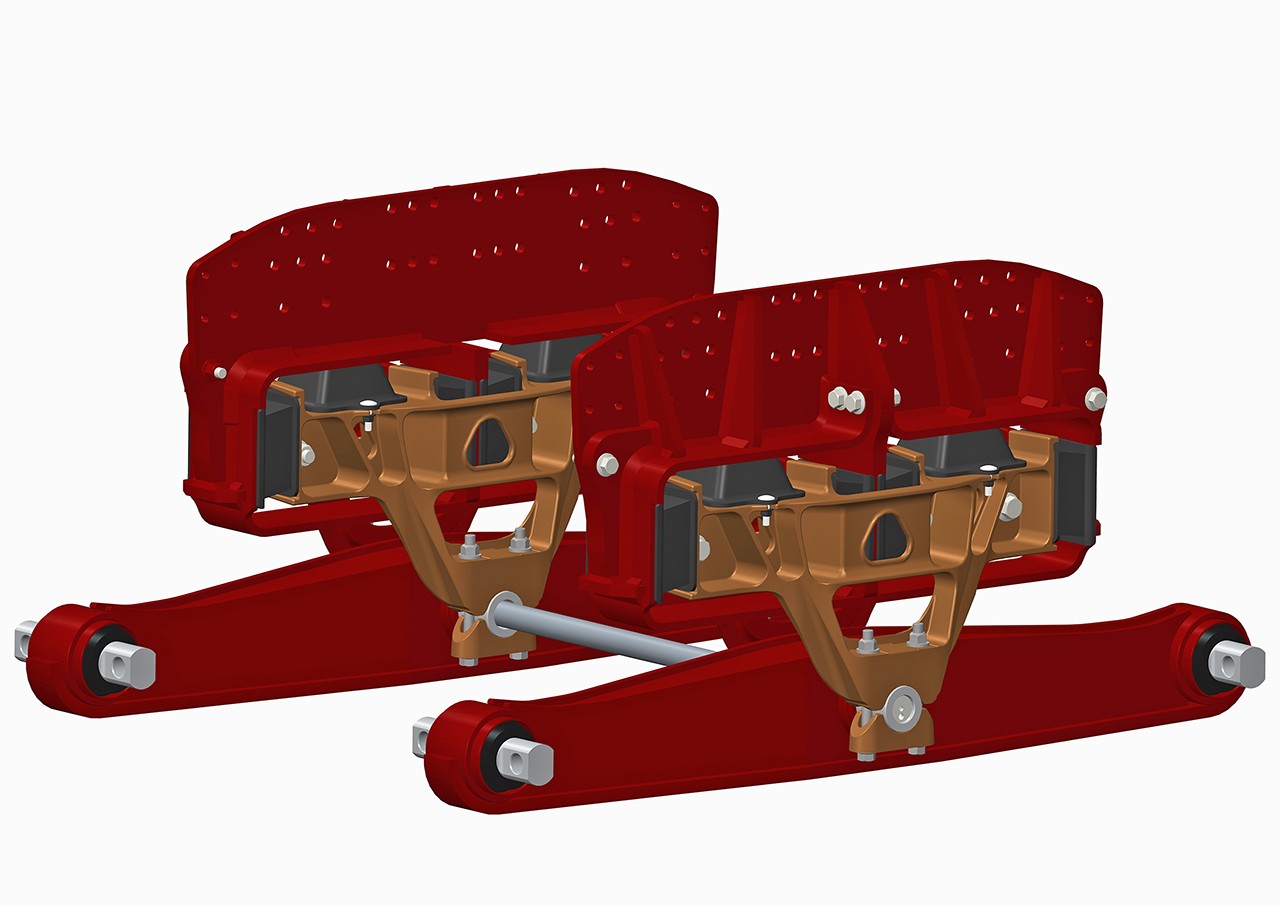

Many customers today are pleased with the ULTIMAAX® suspension, which Tata Motors debuted at EXCON 2017 in its heavy-duty tipper. This gratification factor, whether in the form of higher returns, lower maintenance or zero suspension failure, is the result of the teams at THSL working tirelessly for more than three and a half years to thoroughly validate and get the product manufactured. THSL, which recently celebrated 15 years in India, supported RPIPL on the site at this particular world record. “The THSL team was always available. They visited the site before the project started and kept all the tippers with ULTIMAAX® suspension up-to-date and ready for the mission,” Kadam informs. “Given the company’s penchant for research and development, we look forward to more such products,” he adds. According to THSL, it was after extensive testing and trials that the ULTIMAAX® suspension was designed for heavy-duty mining applications for both 6 x 4 and 8 x 4 tippers. The design and construction was based on feedback from tipper operators who were till then using traditional and bogie suspensions. THSL settled on a product that provides exceptional stability, driver comfort and equipment protection with the suspension requiring more leaves and an anti-roll bar to meet the Indian road conditions. The ULTIMAAX® suspension has now proven to be a significant cost-cutting measure for Indian tipper operators.