The Indian commercial vehicle market is fast-moving, from being heavily focused on initial vehicle acquisition cost to one that prioritizes Total Cost of Ownership (TCO). A number of factors have driven the change which is a welcome one considering that all the major stakeholders are set to benefit from it, with the overall market maturity going up significantly.

A simple definition of TCO would be ‘the cumulative cost incurred at the asset level from its acquisition to disposal’. For fleet managers, TCO is crucial to understanding the operating cost of assets in order to make informed financial decisions about the fleet, take bidding decisions on contracts, etc. Understanding the cost elements of TCO and how to calculate is essential to minimize TCO for fleet managers.

The commercial vehicle and fleet management industry is exponentially expanding and so is the need to understand how to maximize profitability in the long term. Let’s have a look at what drives the commercial vehicle market in India.

Key operating costs

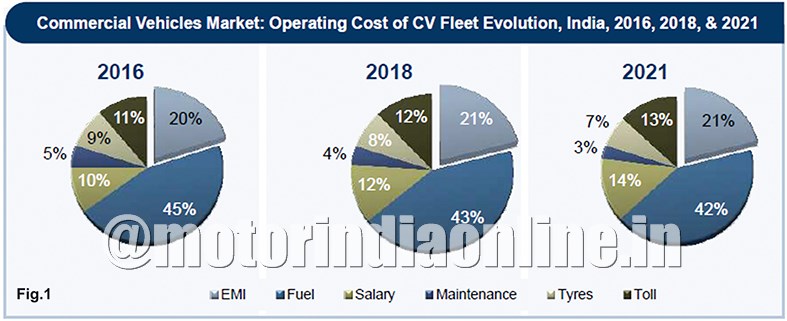

For the Indian fleet Industry, fuel consumption is undeniably the most important factor that contributes to the operational cost and TCO. The other factors significantly affecting operational costs are vehicle EMIs, driver salaries, maintenance and tyres, as illustrated in Fig 1.

In 2018, fuel consumption contributed to 43 per cent of the total fleet business expense while 21 per cent went to vehicle EMIs, proving that solely optimizing fuel expenses and vehicle maintenance can substantially reduce the TCO of Indian CV fleets.

According to the reference source of the figure below, fuel prices are expected to increase in the future for sure, but the tolls and salaries are likely to increase faster and continue to be significant contributors for TCO.

- Vehicle EMIs: An important factor

CVs are typically leased over a three- or five-year period and the resulting EMIs and vehicle depreciation are factored into TCO.

- Preventive maintenance is the key

Vehicle cost includes wear and tear of vehicle components. Replacement of components and parts can vary from vehicle to vehicle, but they add up to the final TCO over a period of time.

Fleet vehicle maintenance costs can be significant for heavy equipment transport vehicles like tractors and trailers. For example, components like tyres and brakes easily wear out because of their constant contact with the road surface.

- Road accidents

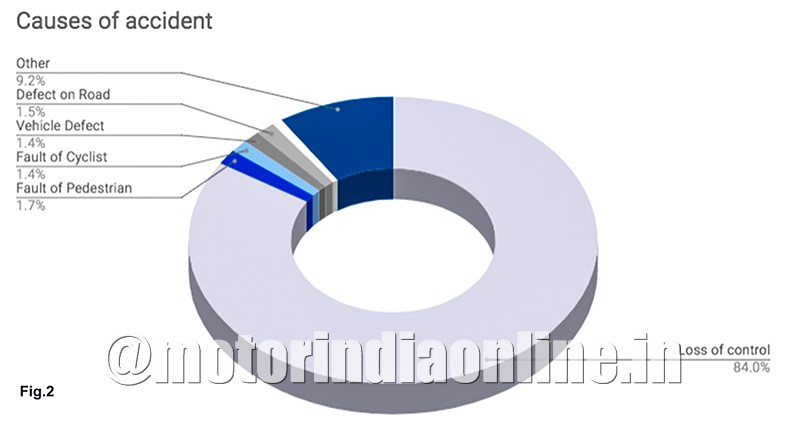

According to the source, Road Transport of India, Ministry of Road Transport & Highways Research, CVs, including trucks, buses and multi-axle vehicles, account for 29 per cent of road accidents, and 84 per cent of the accidents are attributed to loss of control, namely, collision, swinging of the road and lane departure. Refer to the Fig.2.

Majority of the road accidents are closely related to driver behavior issues. Reckless behavior on the road like over-speeding, sudden breaks and sudden accelerations not only put drivers at risk but also increase the risk of major accidents, which in turn bring in unexpected costs.

Driver training and strict driver behavior monitoring practices can benchmark the performance of the drivers and create a preventive environment.

The driver behavior monitoring system helps fleet managers identify the areas of underperformance contributing to accidents, provide alerts to drivers, send customized reports via app on fleet manager’s mobile phone or desktop.

Based on the live statistics of how many times the drivers pushed sudden brakes or acceleration and went on a deviated route along with fuel mileage reports, drivers’ score can be reviewed.

- Need for fuel consumption tracking

A successful CV fleet would be able to identify the importance of effective fuel consumption to overall business profitability. With the petrol and diesel costs slowly rising every year, fuel consumption has become one of the most important numbers in business accounting.

Fuel leakage and theft, unwanted fuel consumption owing to ineffective vehicle route management and never-ending traffic jams can unknowingly increase fleet manager’s business expenses by about 30%, and that is a huge amount in the long run.

- Tyres: Improve fuel efficiency and safety

Tyres are the most overlooked auto parts in spite of their constant contact with the road surface amidst ever-changing weather conditions.

Safety, cost and compliance are three of the major factors fleets need to consider when determining their choice of tyres and when to replace them. Tyres wear down over time, but other problems can cause them to wear out faster and unevenly, costing more money. Tyre replacement can cost $80 to $800 depending on the tyre size, tyre brand and the type of the vehicle.

According to sources, a truck tyre has a lifespan of 50,000 to 60,000 km compared to a life span of 40,000 to 50,000 km for a car tyre, and this lifespan can considerably improve with proper maintenance and monitoring using a Tyre Pressure Monitoring system.

AssetTrackr’s TCO solution

AssetTrackr comes with an expansive bouquet of solutions that include Fleet Management, Fuel Management, Tyre Pressure Monitoring and Driver Monitoring Solutions that monitor vehicles at a micro level, including fuel pilferage, recurrent tyre damage, unwanted route deviations, rash driving and optimizing the day-to-day operational costs. The company works with a number of leading CV fleets across the country and has helped them cut down TCO significantly and boost their profits proportionally.