By Swamini Kulkarni

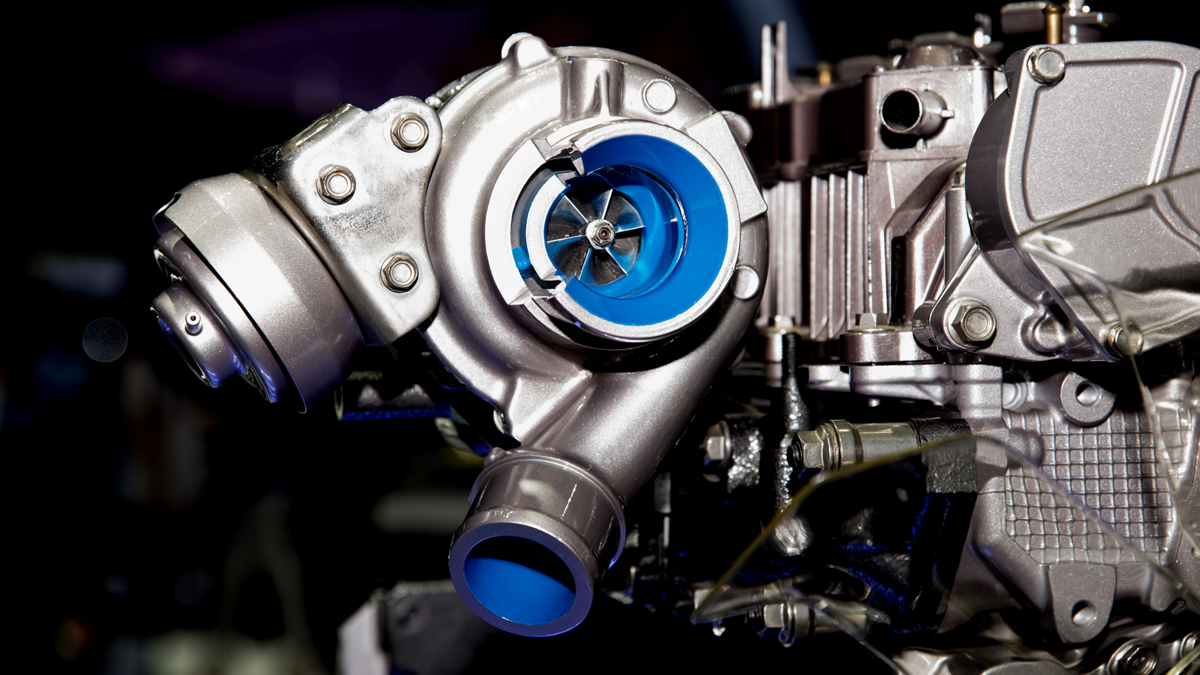

Automotive manufacturers have put much pressure on improving the fuel consumption of the vehicle to reduce the CO2 emission. Ideally, a vehicle engine should offer both high power density and low fuel consumption. That’s where turbochargers with a wide flow range come into the picture. Today, turbochargers have become instrumental for all diesel engines and the majority of gasoline engines.

Fuel efficiency is the one of most critical concerns among both manufacturers and customers due to skyrocketing fuel prices and the limited availability of fuel. Thus, the developing most efficient engines that can meet the Corporate Average Fuel Economy standards is the prime goal of market players.

Recent developments in turbocharger industry

According to Allied Market Research, the global turbocharger market is expected to garner $24.23 billion by 2027, growing at a CAGR of 5.3% from 2020 to 2027. The need for engine downsizing to reduce vehicle weight, government regulations, and improved engine performance and fuel efficiency drive the demand for turbochargers.

The modern turbochargers offer several advantages over the traditional engines such as increased air intake in the combustion chamber, reuse of exhausted air, and high engine performance. As turbochargers work perfectly in high-speed engines and do not demand additional power sources to operate, more and more automotive companies have been including twin turbochargers in their models.

Recently, Toyota launched LC300 Land Cruiser with twin turbochargers V6 engines that offer 415 horsepower and 480 pound-feet of torque. Moreover, both engines are made with 10-speed automatic transmission and according to Toyota, the turbochargers help reduce fuel consumption and emission of harmful gases. Such rapid launch of new automotive with one or more turbochargers has boosted the market growth.

Similarly, the Nissan Z sports car is expected to launch new models with a twin-turbo V6 engine with a novel retro-infused design. The new vehicles are expected to unveil in late 2021. The two-turbo 3.0-liter V6 is more powerful than the previous engine of 3.7-liter V6 of the 370Z. The new vehicles are said to offer 475Nm of torque, which is 30% more than their predecessors.

On the other hand, Mercedes-Benz’s AMG performance car division stated that the company has been working on developing electrically-assisted exhaust-gas turbocharges and it would launch on the coming generation of vehicle models. The technology was developed for Formula 1 race car engines and it would replace the conventional turbochargers that are used on gasoline engines.

Trends in turbocharger innovations

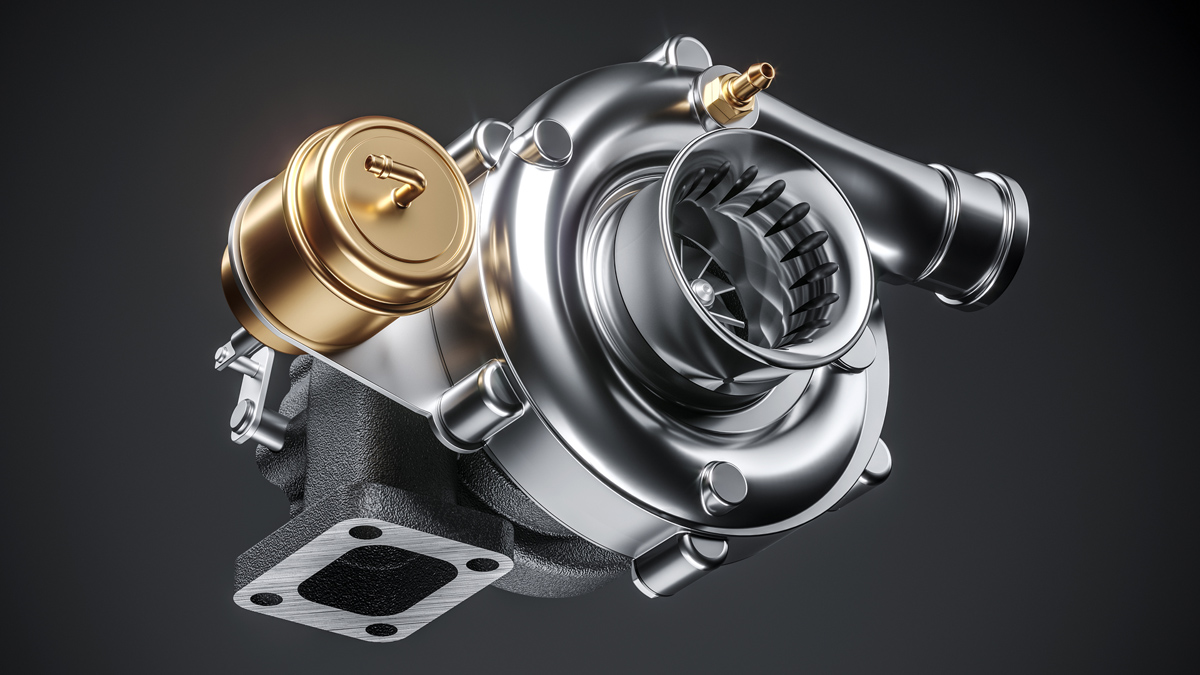

Emergence of improved materials

As the one side of the turbochargers would face the exhaust stream, heat would remain an issue. Moreover, the vehicles will consume extra fuel just to reduce the temperature of the exhaust stream and keep the turbocharger operating. However, the increase in R&D to use a novel set of alloys, such nickel-alloy and stainless steel instead of iron, to manufacture turbochargers that could withstand hit without compromising the vehicle efficiency.

Analytical tools to redefine turbo

The powerful computer models and analytical tools have offered new opportunities to rethink the traditional design of turbochargers. For instance, a small tweak in the shape of blades could improve the overall fuel efficiency and computer models of turbos with lighter materials could help reduce the overall weight of the vehicle.

Smart sensors

The advancements in sensor technology can detect engine-killing detonation. In addition, sensors combined with fast-reacting engine computers, the sensors can improve ignition timing without concern about detonation. Modern turbocharged engines can electronically monitor and control several parameters including cam timing, turbo boost, and the throttle, which can dramatically minimize the pumping losses of engines.

Future of turbochargers

Turbochargers are no new to automotive manufacturers. Throughout history, turbochargers made an appearance in vehicles even when their use was not very popular among customers. However, engineers continuously worked on the earlier versions of turbochargers till the vehicles with turbochargers gained popularity as they offered the same power as the engine twice their size.

In the future, the advent of novel technologies would certainly help turbochargers to improve. Variable turbine geometry (VTG) has already gained popularity in smaller diesel cars and two-stage turbo systems would gain importance soon due to their economical benefits. The manufacturing companies are expected to invest a colossal amount of money in R&D in turbochargers to minimize friction and inertia and improve response.

Electric turbochargers would be the next big thing in the industry and they would enable vehicle manufacturing companies to move smaller engines without cutting down power delivery and compromising efficiency. In the next few years, the turbo lag would be rarely used. Although the electric turbochargers would face many challenges, the emergence of analysis and optimization tools and software would help overcome those challenges and help create new turbochargers that help power futuristic vehicles.

****

About the Author

Swamini Kulkarni holds a bachelor’s degree in Instrumentation and Control Engineering from Pune University and works as a content writer at Allied Market Research. She is deeply fascinated by the impact of technology on human life and loves to talk about science and mythology. When she is not glued to the computer, she loves to read, travel and daydream about her areas of interest. She can be reached at swamini.kulkarni@alliedmarketresearch.net.