J. Schmalz GmbH becomes the first company on the market to develop a new series of vacuum and pressure switches that open up completely new communication possibilities and make processes much more transparent. The VSi version is easy to integrate into systems and makes vital process data visible. The switch communicates with all conventional field-bus systems via IO link and also allows you to readout information using a smartphone.

Visualization of process data in vacuum automation is becoming more and more important. The user needs relevant and reliable information about the state of the system and its individual components. The new electronic VSi vacuum and pressure switch from Schmalz measures and monitors low and excess pressure in automation and handling systems. The digital VSi switch can be integrated into existing systems with minimum effort via IO link. The recorded status data reaches control level rapidly via the IO link interface. For the system operator, that means more transparency, diagnostics and parameterization and shorter response times in the event of faults or errors.

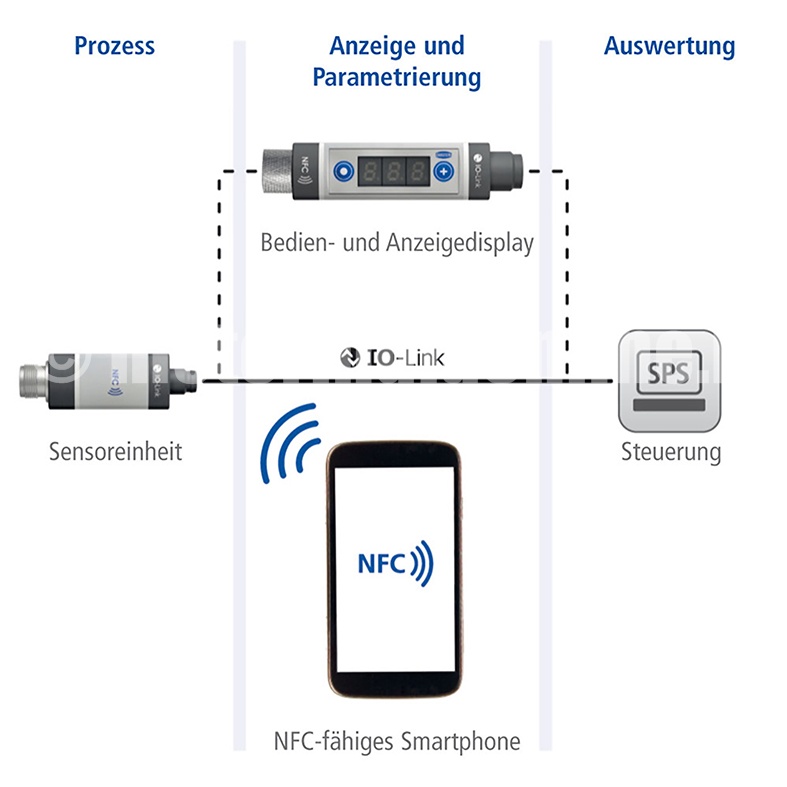

You can choose between a pressure, vacuum or combined version, depending on the application. An integrated or external operating display visualizes the data. The compact sensor unit can be installed in the system independently of the display (directly on the suction pad, for instance). In decentralized vacuum systems in particular, that makes it much easier to monitor the process. The exact measurement is then taken in the middle of the process when the reading is at the suitable point, in the view of the user. Settings like switching points can be adjusted with the external operating and display element and transferred to other switches. The same also applies to switches that do not have a display and buttons.

Users can also effectively carry their display in their pockets if they have an NFC-compatible smartphone. Thanks to Schmalz’s innovation, users can exchange data over short distances using near field communication. The necessary point-to-point contact between the switch and smartphone ensures access to the desired device even without a power supply. The energy required to do so is supplied by the smartphone. That allows the user to receive important service and maintenance information directly on his or her mobile end device, such as serial and order numbers or operating instructions in the event of faults.

The switch provides information about basic settings and process settings via IO link and NFC. LEDs located around the switch make it clear whether switching points have been reached and an operating voltage is available, even from a distance. Real-time warnings for defects are vital for predictive maintenance, helping to prevent them from developing into major faults. With this in mind, service information and detailed error messages are displayed in plain text at control level and on the smartphone to allow the operator to react quickly.

Schmalz has also developed the VS-type vacuum and pressure sensor for use in highly-dynamic handling systems. The sensor has an analog output signal and works without an IO link or external display, but can also still be read using NFC on the smartphone.

Some of the vacuum generators also forward important process data to control level. At Schmalz, IO link technology already comes as standard in a wide variety of ejectors. Likewise, the new NFC communication medium is set to be used again in the upcoming product generations.