Visteon India is uniquely positioned to meet automakers’ needs for smart, digital cockpits for electric and automated vehicles. Their technology ensures that driver and passengers can interact easily, efficiently and more safely with features in the cockpit – and with the ecosystem around the vehicle, discovers Rajesh Rajgor in this exclusive interaction with Aashish Bhatia, Vice President and General Manager, Visteon India

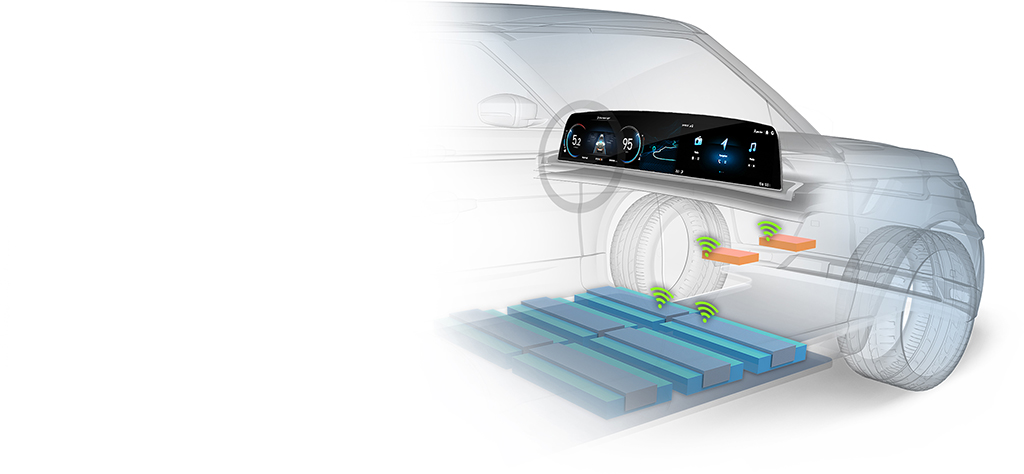

Visteon India (Visteon) is well-positioned to address manufacturers’ needs for smart, digital cockpits for electric and automated vehicles. It is dedicated completely to cockpit electronics and has the widest product portfolio in this market. Supporting the mobility sector and committed to making driving more fun, connected and secure, Visteon’s platforms make use of tried-and-tested, scalable hardware and software solutions to help its automotive customers evolve toward digital, electrified and autonomous vehicles. Digital instrument clusters, displays, android-based infotainment systems, domain controllers, advanced driver assistance systems and battery management systems are just a few of the products.

“Our technology makes it possible for drivers and passengers to engage with cockpit features and the environment around the vehicle more conveniently, effectively and safely,” shares Aashish Bhatia, Vice President and General Manager, Visteon India. Due to competitiveness, every OEM tries to set itself apart from the competition. The buyer today makes the decision that their vehicle must be new and up-to-date. “The cockpit design and ADAS (advanced driver assistance system), which is making driving safer overall, can be the defining factors. Therefore, we need to carefully package the information with a very smart HMI (human touch interface), UI (user interface) and UX (user experience) rather than simply overloading the driver with information,” adds Bhatia.

As the automotive industry become more adaptive to apps, connectivity and the simplicity of interacting with displays, the new user experience towards autonomous driving future will shape up. Bhatia emphasises: “We combine new technology with the best of the consumer electronics experience while using the knowledge and enthusiasm of our employees who are passionate about the automotive industry. We apply our software-driven expertise to succeed in these areas. We also value teamwork, making it simple for the best algorithm and app developers to build revolutionary applications for our platforms, ranging from infotainment to autonomous driving.”

Resources for Success

Visteon has one manufacturing plant in Chennai and six technical centres across the country. Close to 2,000 engineers serve the automakers on different products and segments. Serving the large gamut of products like instrument clusters, infotainments, displays, domain controllers and automated solutions across two-wheeler, passenger cars and commercial vehicles, Visteon delivers tailor-made solutions for the OEMs. Bhatia adds: “We have our own talent pool that is designing these products in India. From a software point of view as well as the mechanicals, everything is being developed here in India at our Chennai plant.”

“We bring to the table a lot feasibility of how we can localise many of these products and bring the right value proposition of the product to make it competitive yet affordable for the end consumer,” he adds. When the stakes are so high, it is important the companies collaborate and understand the unique requirements. These products cannot be developed without being on the same side of the table with the customer, or in other words, collaborating and partnering with the customer. In order to build a product which will be launched couple of years later, the product development cycle has to be in-sync with market requirements. In a world where majority of things are customised, a brick-and-mortar approach doesn’t work too well. There has to be a balance between customisation and standardisation. It will also help us control the costs.

Ask Bhatia how they collaborate with different customers and balance customisation and standardisation of products, and he says: “What we look at is maximum reuse, minimum re-engineering. These are our main pillars around which we work. We have a hybrid approach where you have certain parts of the whole system, which are like building blocks – software. Within the software, thanks to our layered approach of this software, there can be certain building blocks that we can reuse. For example, if you have to use a FM radio, there is hardly much difference in the logic in which you would interact through an FM radio between one vehicle and the other vehicle. The top layer or the HMI layer will have to be obviously customised for each customer, but at least the engine that’s driving all of these can be reused.”

A Growing Reputation

The product portfolio that Visteon delivers and its innovations have been blending nicely with the market trend. The business boasts of an impressive resource base in India, including people and software technology. “We can see that all the factors are perfectly aligned. We have established a solid reputation with many OEMs in India. I have no doubt that our company will have great success in the future. The manufacturing team and the design development team work closely together, resulting in a seamless launch for the customer. We currently hold a market share of close to 40% in India’s cockpit design segment,” claims Bhatia.

“Regardless of the drive-train, the growth trajectory will be very, very favourable moving ahead,” he adds. Visteon, in short, is a global technology firm that provides services to the mobility sector and sets trends instead of following them. Visteon has established a solid presence in the digital cockpit for cars, trucks and two-wheelers, and is now using that core knowledge of battery management to offer the first wireless battery management system in the industry. “We have also expanded our portfolio beyond the electronics into battery management systems. We have already shipped more than 1 million units worldwide,” Bhatia confides.

“We have a strategic partnership with several global top players. All their electric vehicle launches until the next two to three years will have a Visteon’s battery management system,” he adds. In a commercial vehicle, when you have these technologies and see connected features that are available with cloud connectivity, it makes a very sensible business proposition. “For the fleet owners to be able to handle all the information that enhances efficiency and makes for a business case is an attractive proposition. Drivers for each of the three segments (cars, CVs, two-wheelers) could be different but they all confluence into one common theme,” Bhatia explains.

“This common theme is that there is a need to deliver a very smart user experience and hence the commercial vehicle ecosystem is also an opportunity for us,” Bhatia states. Visteon is also investing in hiring the right talent that can handle the real complex work and be part of the transformation that is happening in the automotive industry. The company has a sound strategy in place to hire right talent as well as hone the in-house workforce. This year they have hired 250 new people for various technology and engineering roles. “We already have a strong technology pool and are constantly looking at elevating their capabilities so that they are able to take on different roles. We don’t merely want to be the poacher of talent, but the farmer of talent,” Bhatia concludes.