By opening the plant of the future, Vitesco Technologies aims to produce various powertrain products such as engine management systems, sensors and actuators, as well as exhaust management components for passenger cars and commercial vehicles, reports Rajesh Rajgor

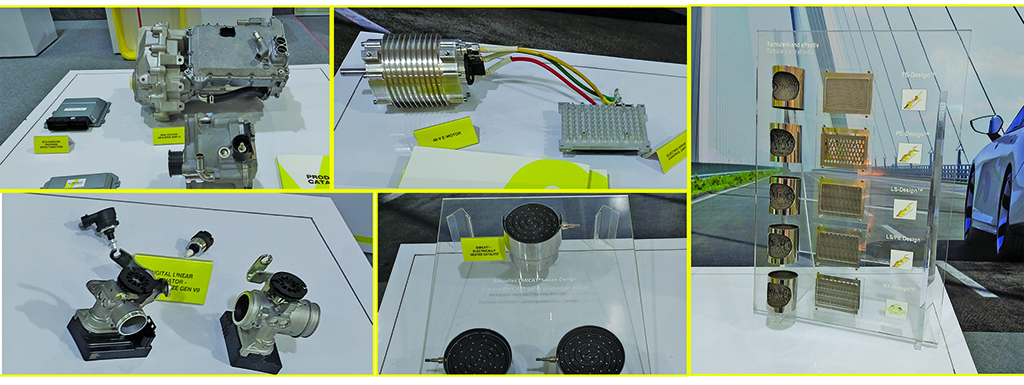

Leading global developer and producer of cutting-edge powertrain solutions for sustainable mobility, Vitesco Technologies provides intelligent system solutions and parts for internal combustion, hybrid and electric drivetrains. Their products improve mobility while lowering costs. The company’s product line consists of electronic control units, sensors, actuators, electric drivetrain systems and exhaust gas after-treatment options. India is presently going through, what may be termed as, the biggest transformation in its automotive history.

“The goal is to achieve a dual technical shift from analogue to digital technology and from fossil fuels to renewable energy. We welcome this change and have started to plan our strategic course. Additionally, the new facility will enable us to more effectively adapt to market demands and changes in the future,” expressed, Klaus Hau, Member of the Executive Board, Vitesco Technologies. Over 900 people shall work at the brand new site, which spans 20 acres and more than 17.580 square metres of industrial space.

The two-wheeler market will receive the first series of productions, which will be followed by a variety of powertrain solutions products, including exhaust management components for passenger cars and commercial vehicles as well as engine management systems, sensors, and actuators. “At this facility, the company will focus its efforts on meeting the rising need for technologies that are highly effective and emit few emissions, as well as electrified and all-electric motor systems. Building this plant was a huge milestone for Vitesco Technologies, allowing us to give better value to our clients in the Indian market,” said Klaus.

Self-Sustainable to the Core

The plant is equipped with a new photovoltaic system that produces 3 GWh of solar energy. The company plans to increase the installed capacity from the current 2.6 MW to 3.6 MW by the end of the year. The factory is also actively exploring automation, digitisation and Industry 4.0 with more than 25 cobots and robots placed on the production lines and shop floor. Vitesco Technologies India Private Limited’s Managing Director and Country Head Anurag Garg stated: “Our aim is to create highly effective, low-emission internal combustion engine technologies and electrification technologies for all sorts of cars in India.”

“We have created a cutting-edge plant for this purpose that is intelligent, sustainable and predictive. We were able to build this facility of the future in Pune because of these essential attributes. This location has witnessed a number of artistic undertakings. Our industrial network’s projects on sustainability, automation and digitisation have helped us to create the plant of the future. We also took climate change into consideration when designing this facility due to the expanding carbon impact. The Pune facility is fully established as a sustainability driver it is functioning at a carbon-neutral level,” Garg added.

Vitesco Technologies’ future plant vision strives to address technological, geopolitical, social, and climatic change challenges that have an impact on society as well as the automotive industry. The business plans to aggressively lead the transformation of manufacturing and supply chain management in the nation. The goal of the company and the new plant will be to demonstrate how Vitesco Technologies will satisfy future manufacturing demands by leveraging innovative ideas and cutting-edge technologies.

—

“Our focus is on offering tailor-made solutions for our customers”

Excerpts from a quick chat with Klaus Hau and Anurag Garg

Although you would want to start with the production of two-wheelers, you said Vitesco Technologies would be focusing on all the segments in the Indian automotive space. Wouldn’t a focused approach in strengthening products for one segment result in expertise and eventual growth?

Klaus: All the three segments are important to us. If you see our success in the Indian market, we have done well on our catalyst offerings like the electronic fuel injection solutions in the two-wheeler segment. We are supporting our customers even for passenger cars on the traditional yet efficient ICE solutions as well as looking forward to the electric solutions that we have already established in some of the other markets. In the commercial vehicle (CV) space, the BS VI implementation gave us a great advantage to bring our advance sensor technologies and actuators into the Indian market. You will also see the same, going forward, from this plant in India.

Anurag: BS VI is still growing and at this time even the electric transition is phenomenal and a certain quantum will come by 2025. The whole idea is to be future-ready for that time (2025), be it in two-wheelers, passenger vehicles or commercial vehicles. Our existing plants are all filled with capacity and we needed a bigger space to combine our mechanical plant activity with our electronics capability. Over the time, mechanical electronics would merge into mechatronics. There are certain products like electronic control units, actuators and sensors that would be rolled out from this plant. We have been able to ensure that our customers’ line is up and running irrespective of market challenges related to the supply chain. Our focus is on tailor-made solutions for each of the automotive segments.

OEMs today expect end-to-end solutions. Right from design to development they want to collaborate with the supplier. How do you approach these working dynamics with the OEMs?

Klaus: We engage with customers at an early stage and especially when the system designs are not yet defined. Here, we bring our expertise regarding the positioning of functionality in order to ensure higher re-use of our platforms. It also results in improved efficiency while prolonged use leads to cost-competitiveness. Our experts work with customers early on and optimise their vehicle system architectures by bringing in our domain knowledge.

Anurag: Today, our relationship with customers is not merely of a seller and buyer. Customers too expect that we engage with them early on in order to give them bigger benefits so that the right products are delivered to them at the right cost.

What is the bandwidth of your engineering centre, research and development when early engagement requires a lot of tailor-made solutions?

Klaus: A strong part of our developments with respect to software and electronics is to build a solid foundation that can be called the building blocks. These blocks can easily be defined and put together for our customers across regions and markets. We also have a strong application team as per the market requirement and line our expertise to integrate with customers’ requirement. Our engineering centre in Bangalore is well-equipped to meet the various demands of the Indian as well as global automotive needs.