Alexander Denk, Vice President (Product Management, E-Mobility, Division Mobility), Voith Group took Rajesh Rajgor through the company’s solutions that address the changes in commercial vehicle mobility

VEDS: E-Mobility for Buses and Heavy-Duty Trucks

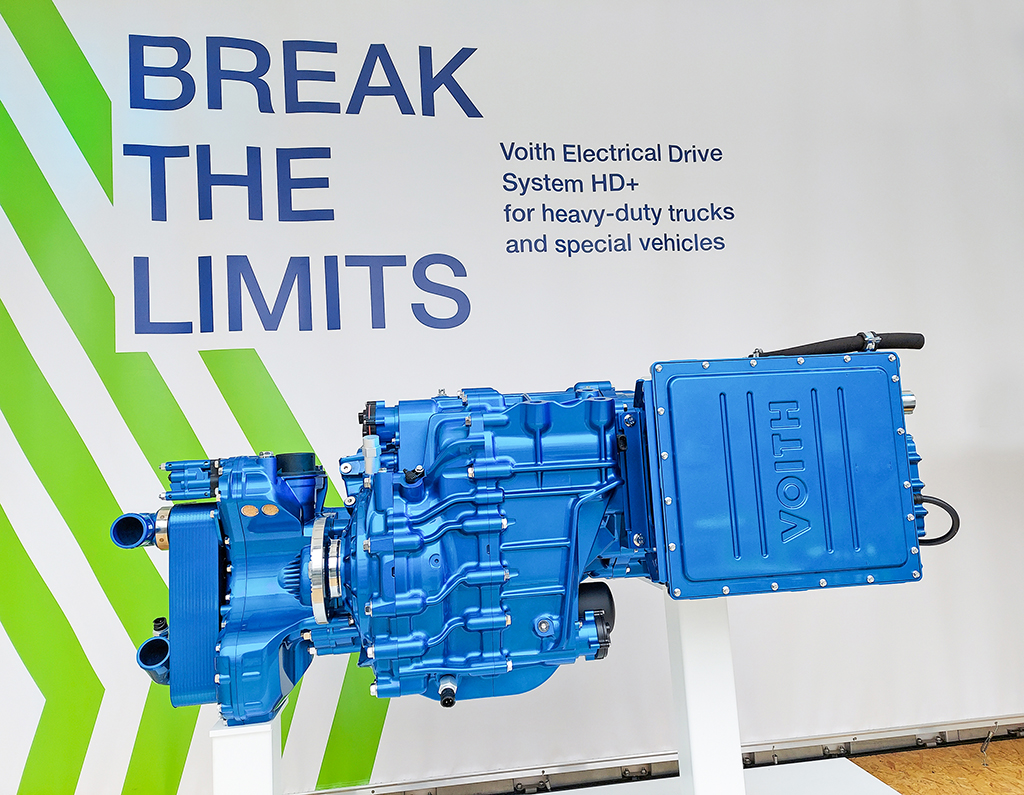

Voith is increasing the scope of its knowledge in the field of commercial vehicle e-mobility. At IAA Transportation 2022, the technology group exhibited the Voith Electrical Drive System (VEDS) and the Plug and Drive H2 Storage System, two ideas that support a transition in heavy-duty truck and bus mobility that are affordable and sustainable. Elaborating about this development, Alexander Denk, Vice President (Product Management, E-Mobility, Division Mobility), Voith Group, said: “The latest product from Voith for truck consists of three main components: 800 V inverter, e-motor with up to 450 KW peak/310kW continuous power and at the back we have a four-speed AMT transmission consisting of two planetary gears and one spur gear.”

“The AMT is equipped with a smart actuator shifting system which has a very short shifting time of up to 0.6 seconds each. At the end we have as an optional retarder in combination with the e-motor so that we can get braking power of up to 650 KW. We have shown this system for the first time at this year’s IAA. The system’s fundamental component is a brand new, cutting-edge automated four-gear electric transmission. As a result, there is always the best traction available, regardless of the driving conditions or the load. It also guarantees that the electric motor always runs as efficiently as possible,” he added.

“Customers can select between two Evo-branded electric motors with top outputs of 330 kW and 390 kW, respectively, for the VEDS HD+ drive system,” he further stated. It is very flexible and easy to apply for 8 x 4, 8 x 8, and 6 x 6 all-wheel drive vehicles. For buses they have a direct drive portfolio without the transmission for achieving the highest efficiency. “We have two different variants available for articulated buses and as well as for the solo buses,” he summed up.

Plug and Drive H2 Storage System

The expertise of Voith as a system provider is reflected by the new Plug and Drive H2 Storage System. In line with its holistic approach, customers receive everything from a single source, from the tank nozzle to the fuel cell inlet, including a patented installation system to accommodate the H2 tanks. Voith uses pre-impregnated fibres, called TowPregs, as material for the tanks, which Voith manufactures itself. The production utilises a special winding process that enables optimised winding layers. This enables higher storage amounts of H2 without any compromises in terms of quality and safety, even with high pressures in the tank.

Here Voith focuses on 700 bar technology to ensure long ranges even with limited installation spaces. Combined with short refuelling times – it takes about 10 minutes for full refuelling of 56 kg H2 which is around 750 km of range for a 40t truck – this results in greater economic efficiency for the operator, compared to conventional systems. The Plug and Drive H2 Storage System is primarily designed for heavy-duty commercial vehicles, construction vehicles and similar applications, where the use of battery-electric concepts does not make sense from an economical or technical perspective. Voith also ensures sustainability and recyclability throughout the entire lifecycle.