Road laying technology in India is undergoing major changes and the future looks smooth and upcoming.

The all-new 9m Volvo Tracked Paver 6820C from Volvo CE is creating ripples among its customers. As against the 7m paver launched in April 2016, this new giant on the block will not be manufactured in India but imported from Volvo’s German plant.

Mr. Dimitrov Krishnan, Head – Sales & Operations, Volvo CE India, shares: “The ABG plant which Volvo acquired in 2007 produces this paver which is designed to perform 700 tonnes per hour. It has power, precision and productivity. It has 193hp at its disposal which can be used at a lower power setting and thus save fuel. We call it Smart Power which can be used at 60 per cent capacity at 1600 rpm which saves about 30 per cent fuel.”

Attractive features

The C series machine swears by its precision features and its ability to control using its electronic paver management system. The control unit, according to Mr. Krishnan, is the actual paver, and since it is positioned to offer maximum visibility to the operator, he can control the different parts of the paver together or separately as per the demand of the work he is doing.

Mr. Krishnan further says: “The paver is like a factory because the material is stored, processed, spread and compacted and all these things can happen simultaneously. The best part is that the controller can be moved from one end to the other for the operator to access the control on whichever side he needs to work on. The operator can actually push the seat outside of the paver for even better visibility. That gives him an almost 360 degree visibility to everything – be it the material flow, the mat coming in, and different issues that crop as the work progresses.”

The P6820C boasts of 13.5 tonne hopper capacity, noise reduction feature along with optional fume extractors. The automatic tensioning track allows the operator to merely start the machine and the track will tension automatically to the right level. In this new paver, the screeds can be extended 3-5 m using hydraulic power and extensions further can be added too. One can assemble the whole screed set in 20 minutes.

In the C series, Volvo offers other power houses like 7820, 8820 and 9820 which are of wider width. He reveals: “With the 6820 we can go up to 9m, with 7820 up to 11m although 10m is the standard, and with 8820 we can go up to 13m paving. With 9820, which is not a C series, we can go up to 16m, covering the entire range for different paving and road building needs.”

Predicting that road construction activity will continue to strongly drive the construction equipment market in India, as it has in the last one-and-a-half years, he hopes that the trend will continue to be high in the coming couple of years as well.

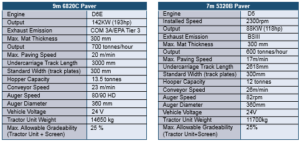

9m vs. 7m

When 7m paver was launched last April, it was pegged as the market standard in India and that it would ‘more or less redefine the market’. But Volvo CE India is confident that the market will welcome the new entrant with open arms.

Comparing the 7 and 9 m pavers, Mr. Krishnan elaborates: “There are applications that the 9m paver can do better than the 7m although the latter is doing extremely well in the market. In India, 45 per cent of roads are still being asphalted, and hence there is a need for a high quality asphalt finish.”

With regard to the compaction feature, he adds: “To give pre-compaction before the asphalt compaction has come onboard, we have actually a standard single tamping bar but you can make it double tamping too. So by the time the machine has laid the material, it is already up to 90 per cent compacted, so the compactor load comes down and, in turn, increases productivity.”

He further adds: “Prior to the 7m paver, 9m was the market standard because it was the 9m which was being used to pave roads with 6.5 to 7m width… meaning it was being under-utilized. The 7m was cost-effective because it is manufactured in India which means the lead time to supply is shorter, in turn, shortening the customer planning cycle. But there are still some more applications for which a 9m paver is needed, especially in cases of asphalt layering at a stretch without any joints, particularly in six-lane jobs. In the last one year since its launch, more than 54 units of 7m paver have been sold in a market which stands at 120 units per annum in the sensor paver market, with the total paver market standing at 700 units annually. The total market in 2017 will be higher at almost 900 units.”

Future trend

In the near future, he feels, the sensor pavers will be the minimum requirement for laying all kinds of roads in India. He says: “It is so because the State and national highways are becoming concrete and hence the requirement of these pavers will be higher. Local mechanical ones do not have their power. So, that will drive the usage of these pavers in terms of volumes. It is the technology of these pavers which wins over the local makes because most of the roads are toll roads. It means that the quality of the finish determines the longevity. No one wants to get into the maintenance situation in three years of building it because it will affect the revenue in that period.”

Also, it is clear that with concrete the base has to be strong, otherwise the top layer can create problems with use, and hence the prediction of an increase in paver sales.

While the P6820C has been launched globally a year-and-half ago, in India it is making an entry now. The trend is changing slowly what with the customers becoming more appreciative of the technology on offer and many features that mean value for money in the long term.

A paver’s life is long, sometimes up to 15 years before it is scrapped. With the Government planning better infrastructure, especially in the form of better roads and highways, Volvo Paver 6820C is all set for smooth cruise down the length and breadth of Indian roads.