Volvo Trucks’ presence at the IAA Commercial Vehicles is a manifestation of the Power of Knowledge. Furthermore, the most recent proof of the company’s outstanding ability to drive progress for customers is its victory in Germany’s prestigious Fehrenkötter long-term, multi-brand test. The test focuses on the total cost of ownership over two and a half years in actual operating conditions. Carried out jointly by German haulage company Fehrenkötter and trade press magazine trans aktuell, it featured seven trucks from seven manufacturers.

The Volvo FH with 13-litre Euro 6 engine and I-Shift transmission came out ahead of all competitors in the 2014-2016 test result, announced in conjunction with IAA. In addition to the lowest total cost of ownership, the FH also had the best fuel economy.

“Even though the Fehrenkötter truck is equipped with our previous powertrain generation, this victory proves that our continuous focus on combining superb productivity and performance with first-class fuel efficiency is a winning formula,” says Mr. Claes Nilsson, President of Volvo Trucks.

Enhanced performance and fuel economy

By developing and manufacturing the entire powertrain in-house, Volvo Trucks ensures optimal integration and communication between engine and transmission. Hardware and software can be tuned to achieve the best possible balance between excellent performance and low fuel consumption.

The integrated powertrain, which was launched earlier this spring, consists of a further-enhanced Euro 6 engine and Volvo’s unique I-Shift transmission. The two most significant engine improvements are a higher compression ratio on the 420 and 460 hp versions and a new optimised turbocharger on the 500 and 540 hp variants of the D13 engine. A number of small aerodynamic improvements lower fuel consumption even further.

“Just how much fuel the latest improvements can save depends on the truck’s specification and application area. For a Volvo FH in long-haul operations, fuel consumption can be reduced by up to 3 per cent. For heavy transports, such as timber haulage, savings may be even higher if the engine is combined with I-Shift with Crawler Gears and Tandem Axle Lift,” says Nilsson.

15-year anniversary of I-Shift

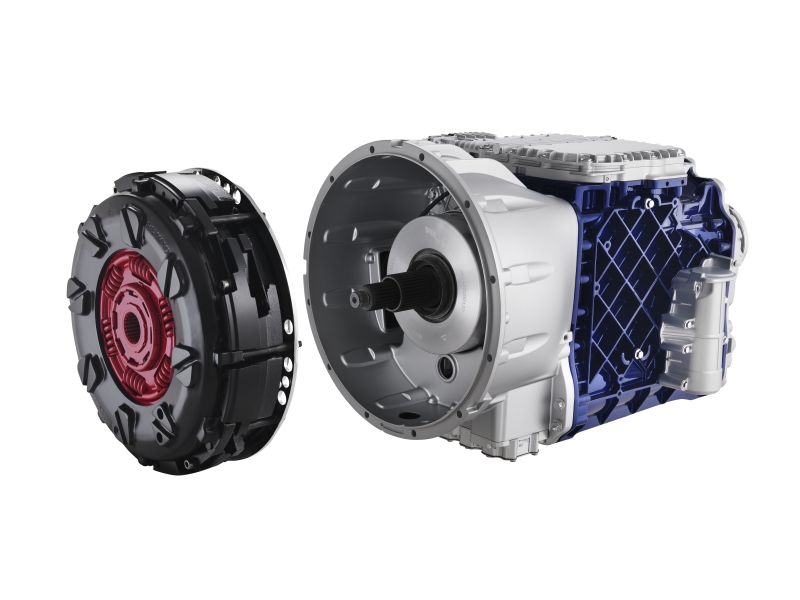

Volvo Trucks’ acclaimed I-Shift transmission celebrates its 15th year on the roads. Over the years, it has moved from a promising upstart to the industry benchmark.

At present, a massive 92 per cent of all new Volvo trucks are equipped with I-Shift. In Europe the share is as high as 95 per cent. The wide range of software choices for the basic I-Shift plus two additional versions with dual clutch and crawler gears give unique customer benefits in all transport applications. The recently introduced I-Shift with crawler gears is a world-first that provides exceptional startability with heavy loads in severe situations. A 325-tonne vehicle combination can start from standstill on uphill gradients of up to 3%. I-Shift with crawler gears also enables a clear fuel-saving potential in long-haul applications. A faster rear axle ratio can be specified, enabling the truck to cruise at a high average speed yet with lower engine revs.

World record with I-Shift Dual Clutch

I-Shift Dual Clutch is a vital part of the powerful Iron Knight performance truck that set two world records this summer, over 500 and 1000 metres, from a standing start. This mean-looking record-breaker is custom-built in every detail apart from its engine and I-Shift Dual Clutch transmission. “The transmission is basically the very same gearbox you find in series-built Volvo trucks. This is truly remarkable considering that it handles 2400 hp and 6000 Nm of torque in the Iron Knight,” he says.

Innovations for the future

The new Volvo Concept Truck takes the Power of Knowledge even further. The concept truck, the result of five years of research, cuts fuel consumption by more than 30 per cent in long-haul operations, mainly thanks to a state-of-the-art powertrain, more aerodynamic design and weight optimisation.

“This is just the beginning. While the Volvo Concept Truck is equipped with our standard D13 Euro 6 engine and I-Shift transmission, the next concept version will feature a new ground-breaking powertrain. We will unveil the details in the near future,” says Nilsson.

Volvo Trucks’ work within automation focuses on applications where the technology enables new tangible customer benefits. Mining operations are one example. The capabilities of a fully automated Volvo FMX were demonstrated in the Boliden mine in northern Sweden a few weeks ago.

“The self-driving FMX operates flawlessly below the ground, fully integrated in the mining company’s production system. It emphasises how Volvo Trucks’ firm focus on innovation powers our unique ability to drive progress for our customers, today and in the future,” he concludes.