Volvo Trucks North America has launched several new integrated powertrain solutions, offering increased fuel efficiency, productivity, reliability, comfort and uptime plus more efficient chassis packaging recently.

Integral to the new powertrain are enhanced design features that were engineered to provide Volvo customers best-in-class performance, productivity, fuel efficiency and an improved total cost of ownership. Volvo’s new powertrain offerings include multiple engine enhancements, such as turbo compounding for the North American Volvo D13 engine, the introduction of Volvo I-Shift with Crawler Gears automated manual transmission, Volvo I-See, and a one-box Exhaust After treatment System (EATS).

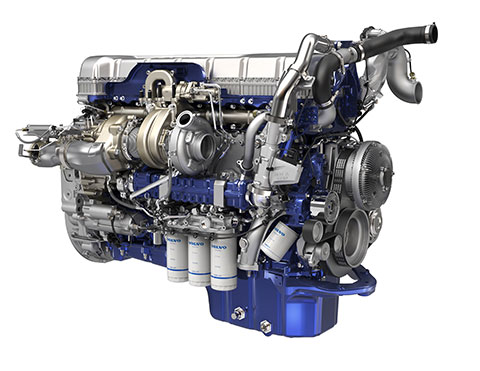

Engine Enhancements – among the news is Volvo’s 2017 D13 engine with turbo compounding, a technology that recovers wasted exhaust heat energy and converts it to useable mechanical energy that is transferred back into the engine. The result is up to a 6.5 percent improvement in fuel efficiency compared with previous engine models. Applications that benefit most from turbo compounding include long-haul, steady-state driving, which is why the turbo compound technology has been developed for North American long haul applications.

In addition, Volvo’s North American 2017 11-litre D11 engine and the 2017 D13 both received numerous updates designed to improve fuel efficiency. These updates alone boost D11 to up to 425 horsepower, while improving fuel efficiency by up to 2.2 percent, and the 2017 D13 will see up to a 2.5 percent improvement in fuel efficiency.

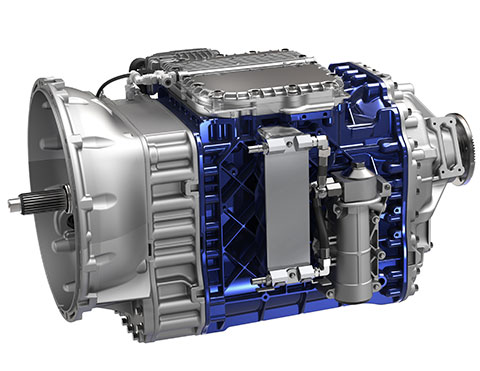

Volvo I-Shift with Crawler Gears – designed with crawler functionality and startability, Volvo I-Shift with Crawler Gears is ideal for applications requiring a slow speed and maneuverability, applications such as concrete mixers with curb pouring capability, asphalt paving, spreaders, dump trucks, heavy haul and line painters. The system is entirely unique for series-produced heavy trucks.

Volvo I-See – Volvo I-Shift efficiency also received a boost from the Volvo I-See system which works in tandem with the I-Shift transmission.

I-See is a feature which learns the topography of the road, memorizes it and stores it in the transmission for use the next time the driver travels the routes. The built-in electronics constantly monitor factors such as road grade, speed, weight and engine load to help maintain the most efficient gear possible to save fuel during the driving cycle.

One-Box Exhaust Aftertreatment System – Volvo Trucks’ new one-box exhaust after treatment system (EATS) combines the diesel particulate filter (DPF) with the selective catalytic reduction (SCR) and diesel exhaust fluid doser into a single unit. The system also features improved low temperature NOx conversion for lower emissions. The new design configuration results in improved efficiency, smaller chassis packaging requirements and a weight reduction compared with a two-box unit.