The Indian commercial vehicle (CV) industry is experiencing a transformation both in terms of technology and product offerings. The Government of India has mandated the roll out of Bharat Stage VI emission norms from April this year. The legislative landscape is fast evolving in India with a strong focus on safety and efficiency norms, which will make CV fleets of the future safer and more efficient.

Indian customers have been steadily increasing their demands towards greater quality, safer, efficient and more reliable products of appropriate technologies at reasonable costs. These technologies have more emphasis on energy efficiency, emission reduction, safety and weight reduction.

In addition, fleets are increasingly focusing on technologies to improve fuel efficiency, enhance driver & passenger comfort, increase driver productivity and reduce Total Cost of Ownership (TCO). One of the key areas of focus is the transmission technology wherein automatic / Automated Manual Transmission (AMT) find their way into CV applications. The growing demand for AMT technologies can be attributed to providing efficient means of maintaining fuel efficiency of a vehicle whilst also improving the driver comfort.

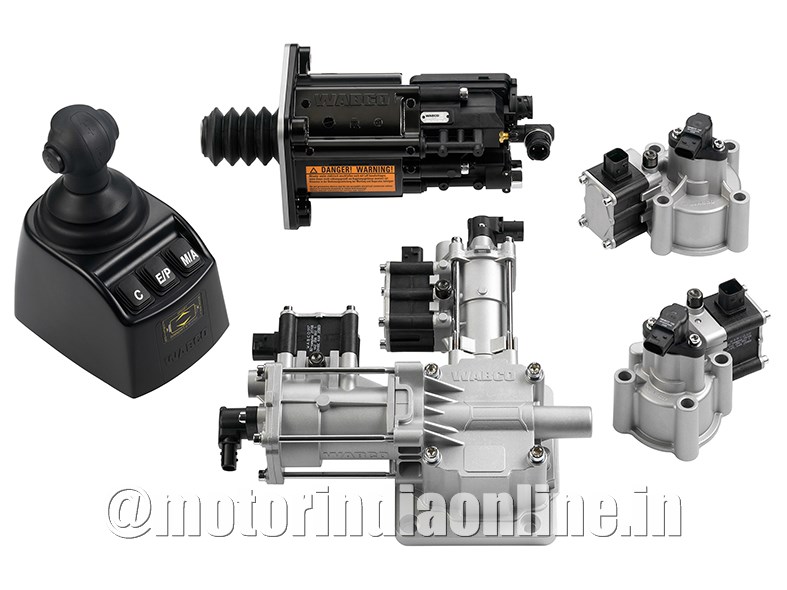

This provides ample opportunities for companies to further penetrate the market with advanced technologies like AMT and enhance the consumer experience. One such technology is WABCO’s OptiDrive, a unique pneumatic AMT solution for the Indian CV industry that is designed to benefit fleets by improving fuel efficiency, enhancing driver comfort, increasing driver productivity and reducing TCO.

Modular system

OptiDrive is an award-winning modular transmission automation technology that can be easily adapted to a wide range of existing manual gearboxes and provides an alternate cost effective and reliable solution for CVs. It combines the comfort and ease-of-use of an automatic transmission (AT) with the efficiency of a manual transmission (MT) and is engineered as a modular system. WABCO’s OptiDrive AMT system releases the driver from frequent clutch and shift operations thereby helping to reduce stress and fatigue and letting drivers concentrate on the road. Optimized gear shifting improves driver effectiveness across all levels of experience.

WABCO pioneered the CV industry’s first AMT system in 1986 in Europe and today WABCO is distinguishably the leading global supplier of AMT for CVs across the world, having sold over 5 million AMTs since its launch. OptiDrive continues to gain acceptance globally among makers of trucks, buses and transmissions in North America, Europe, China, India amongst other parts of the world.

Smooth operation

OptiDrive automatically engages the vehicle’s clutch and gear shift actuation. Gear shifting is done by electro-pneumatic actuators receiving control commands from the on-board computer.

AMT performs gear shifting taking inputs such as engine torque, vehicle load and road gradient. It optimizes clutch and gear actuations reducing wear of mechanical components, thereby lowering Total Cost of Ownership.

OptiDrive™ provides two gear shifting modes for vehicles: manual and automatic. In the automatic mode, the electronic control unit selects the most suitable gear and completes gear-shifting according to engine speed and torque, position of accelerator pedal, vehicle braking state, vehicle load and road conditions.

In the manual mode, gear shifting takes place based on the input from the driver. The clutch actuation takes place automatically during both shifting modes (Auto & Manual).

Buses or trucks fitted with AMT do not have a clutch pedal and gear shifting lever – instead there is a selection lever unit which can also be utilized for manual override. The clutch control and gear shifting are taken over by the AMT system. Gear shifting is done by electro-pneumatic actuators receiving control commands from the on-board computer.

Once a design is configured for a particular gearbox, it can be retrofitted in the model with the help of WABCO’s technicians. Its adaptability to existing MTs makes it a preferred choice of most of the CV manufacturers in India.

Easy adaptability

OptiDrive™ is a complete system that includes AMT hardware and shift software. Its patented technology enables fully autonomous gear shifting and clutching. OptiDrive easily adapts to a wide range of manual gearboxes through innovative modularity platforms. It minimizes space requirements at the gearbox and is available for 5-speed up to 18-speed applications.

WABCO has developed a single product platform to cater to the need of multiple driveline / vehicle platforms of various OEMs. Considering customer requirements, where time and cost is a big factor, it reduces by approximately 50% the development time required for vehicle and transmission makers to apply OptiDrive to their vehicle platforms. This time reduction is in relation to the integrated AMT used by global OEMs. The hardware is designed for AMT integration while in OptiDrive the existing hardware is adapted with some levels of customization.

On the software side, the base software for transmission shifting/ clutch control/ gear detection is a common modular software that is adapted to the individual vehicle platforms and not developed from scratch. To ensure gear optimization, WABCO has its own proprietary software algorithm which is developed to ensure improved performance in terms of drivability and fuel economy. This algorithm aids to select the optimal gear and clutch positions.

Retrofit solutions

OptiDrive can be fitted in all released vehicles as a retro-fitment and provides better fuel efficiency, driver comfort and lower maintenance cost. OptiDrive significantly reduces mechanical wear, lowers maintenance costs and vehicle downtime. It simplifies vehicle handling, increases driver comfort and enables comfortable, smooth & safe driving like an automatic transmission.

Advantages over MT and AT

AMT is an improvement over MT and provides benefits of AT at lower costs. It can be integrated into the existing MT and provides significant advantages in improving driver and vehicle performance. Typically, the payback is between 6 to 12 months depending upon the vehicle’s operation period. OptiDrive significantly reduces mechanical wear, lowers maintenance costs and vehicle downtime. It simplifies vehicle handling, increases driver comfort and enables comfortable, smooth & safe driving like an automatic transmission.

Benefits for fleets

- Achieves approximately up to 5% fuel savings compared to manual transmission

- Reduces mechanical wear lowering maintenance costs and vehicle downtime

- Minimizes driver fatigue by releasing driver from clutch and shift operations

- Simplified vehicle handling aids driver recruitment and retention

- Improves driver effectiveness across all levels of experience

- Enables comfortable, smoother and safer driving to ensure cargo delivery on time

Benefits for OEMs

- Applies to different vehicle platforms: light, medium and heavy-duty vehicles

- System’s flexibility shortens time-to-market by up to 50 % approximately

- Reduces development cost by more than 80 % compared to a customized AMT solution

- Offers unique calibration tool myOptiDrive™ to tailor system performance to specific customer preferences

- Experienced application engineers support customers from concept to serial production

- Helps reduce fuel consumption and carbon emissions leaving an environmentally cleaner footprint