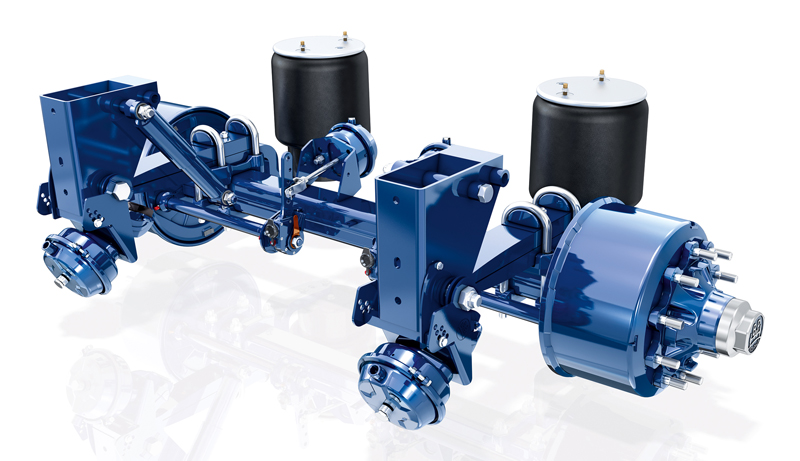

In this exclusive interview with Nagaraj Ubale, Director (Technical), BPW Trailer Systems India Private Ltd., Rajesh Rajgor finds out how the company resumed operations post the lockdown, about their new 12 T and 14 T air-suspensions for the new 54 T and 55 T GVW tractor-trailers and consolidation efforts to provide complete trailer solutions including axles, suspensions, landing gear, mudguard, lighting systems and spare parts to customers

Could you give us an update on the current status of BPW India’s operations, especially after you reopened post the lockdown?

We did our last dispatch on March 22, 2020 before we went into the lockdown phase. Post the lockdown, we began with 33 per cent work force and it was a bit difficult to operate with less manpower. Most of the executives were operating from their homes and even now a few of them are at their native place and functioning from there. So, we have made peace with the new normal and that is how it is now. From the service perspective, with the truck movements starting in the phase of Unlock 2.0 we could serve our customers in Rajasthan and the NCR region. Nearly 60 to 70 per cent of our premium products are deployed in these two regions. Our team in East India reached most of the customers.

They even conducted medical camps for drivers’ health and undertook medical awareness projects related to the impact of the corona virus. It was indeed tough since nothing much was moving during the lockdown. Yet, most of us managed somehow or the other. We are really thankful to all our customers; you know that there was some concern regarding registration of BS IV vehicles just before the lockdown and all those vehicles were stacked up during that particular period. There was chaos to clear up the inventories. We had confirmed orders during that time and were therefore able to pick up pace after the easing of the lockdown when we started commissioning orders. With the support of the local manpower that worked over weekends to complete the orders, we were able to fulfil the requirements.

What is the status of the 54-tonne GVW tractor-trailer with air suspension on the trailer side? How have your customers responded to it? Do you have any more new products that are in the pipeline?

BPW India started working on the air suspension side when the axle load norms came into the picture in 2018. Therefore, from that point onwards changes have been happening in the industry and we see this as an opportunity for us to advocate our premium products in the market. There were efforts from the government side to push for advantages of axle load on the air suspension side. That’s how the journey started and we were able to convince our customers with the different applications of our premium segment. We could convince our customers to go with the calculation of total cost of ownership (TCO) with return on investment. We conveyed this and also helped implement some of the applications like tip-trailers in steel and cement markets. We are thankful to all our customers who trusted us; today they are highly satisfied with the quality. And that is how we are adding volume now.

How did you support customers with the new axle load norms? What was the impact of the 54-tonne air suspension during the transition?

Since the onset of the axle load norms, we identified the changes that would impact the trailer industry. There were factors like spread axles concepts and independent axles ratio coming into the picture. When you have separated one of the axles from a bunch of these axles there is a different kind of axle load that is going to add to and increase the loading capacity of the vehicle. We identified this in October 2019 as one of the customers thought of a spread axle concept. This was in Jharkhand with all the complete air suspension inside. It has been running successfully for eight months now and that itself speaks volumes about the 54-tonne GVW 4 x 2 tractor trailer with air suspension. The point which I want to mention here is that it’s all about the concept of spreading the axles and be it a tandem vehicle or a tridem vehicle it is going to impact the complete gross vehicle weight.

How do you deal with the customization that customers ask for? Can you also throw some light on the variants that you offer to your customers?

Things are now getting organised in the Indian trailer industry. Even though slow, it is still a very price conscious market. Hence for BPW India’s premium products we have also focused on localisation. Today our mechanical suspension is 100% localised and the air suspension is nearly about 40%. BPW India is competent in offering complete solutions for axles and suspension together from India and will be also be able to meet the price expectation of our customers. Our premium products are well-accepted in the off-road and on-road applications like tanker, steel and cement.

What are the other trends that you see emerging in the Indian market from BPW Group’s global experience?

We are seeing the impact of axle loads and then we have impacts of dimensional changes to be felt. Whether it is a semi-trailer or an articulated trailer, it is good to see a very aggressive push from the government side for this regulation. The government has also touched upon the subject of road-train systems and these are a few concepts that are going to come in the future. We have also seen changes in terms of vehicles migrating from BS IV to BS VI. It’s a wonderful opportunity for all of us in this industry to consolidate prime movers and trailer solutions together to give a complete tractor trailer solution. This is what the customer is looking for. We set a fine example of this when we delivered our product and complete solution for Volvo’s ‘Delhivery Express Cargo’ project that is really a breakthrough premium product where we were able to convince the market that price is not the criteria. Rather, the output and return on investment is!

How would you sum up BPW India’s journey over the last one to two years? What are your expectations for 2021-22?

There were two-three perspectives from our side which we analysed at the end of 2018. One is about a cost-effective solution for price-sensitive market with focus on localisation. Another is to offer technology-oriented products for a premium segment. We started the development of the products as per the needs of the customer. While doing so we convinced our customers about the premium products and also identified the right customers while proving the value of the products on the ground level. Within a span of one and a half years we could emphasize the importance of air suspensions that was earlier unknown to the market.

We implemented it for off-road applications like tip trailers for the mining segment and cement bulkers, flatbed and sidewall trailers, etc. Looking at the future, particularly in 2021, the value proposition we provide to the customers will come into place and offer really bright prospects. Prior to axle load norms in 2016-17, we hardly sold any air suspensions in the market. In 2018 this jumped to nearly about 70% and we continue to add to it with our premium products as we work with most of the transporters, trailer manufacturers, and also the OEMs. There may be solutions in the future that will help us acquire 30% of consistent market share.

You sound optimistic and happy that there are certain right developments with respect to government laws and the overall approach of the industry towards safety and flexibility towards independent trailers and registering prime movers separately. Do you feel the Indian market is moving in the right direction as far as the trailer industry is concerned?

Yes, today the industry has accepted the trailer code and rather than the government regulation enforcing it pan-India, there is awareness for quality products. Most of the trailer manufacturers are certified and as people are eager to work in an organised way the OEMs are also going to be very optimistic about the overall product acceptance and right products for the right segment. On the application side, I think it will be better to offer a complete tractor-trailer solution including axles, suspensions and spare parts to customers and that’s going to change the future market and make business sustainable for everyone in the Indian tractor-trailer industry.