Make quality products for global markets, make them faster, make them better but make them at a bare minimum costs – that’s among the many challenges a global Original Equipment Manufacturer (OEM) faces today. This means OEMs must reexamine their long-held canons of product engineering, get the cost economics right, and deliver on a whole-new mandate.

Rachel Smith is one of the several engineers who is helping global manufacturers do just that. Rachel works for a specialty provider in the engineering outsourcing services domain and is based in Novi (Michigan) as its CAD/CAM manager. Her responsibilities include analyzing engineering drawings as well as designing data to determine the dimensions and configurations of cuts, choosing the right set of cutting tools, and setting the cutting machine to the right speed. She is currently on a project to design a powertrain (engine and transmission). Rachel’s team is through with the preliminary design and it has gotten a grip on the basic configuration of the powertrain.

As a next step, Rachel and 10 of her colleagues get busy working on a virtual model of the product. Soon they are joined by another 15-member team led by Ethan, a modeling engineer from the Brasov (Romania) facility of the company, thousands of miles away. The virtual collaboration platform lets the teams validate different elements of the powertrain – all the way from cradle to grave – for performance, fuel consumption, and lifespan. This also helps them understand how the powertrain system will respond or will handle different scenarios over its lifetime.

The powertrain designs are intended for a leading maker of cars, buses, trucks, and defense vehicles and will go into production at the client’s facility 8,000 miles away in India, which verges on bigger markets like China and Thailand. Before they electronically transfer product design documentation to this remote production facility, designers in Novi must ensure high quality of designs, so there is little or no chance of rework later on. And because the client sells vehicles in more than 50 countries, it is important for the design team to share design information, processes and tools with production units peppered across these countries.

Global engineering centers (GECs), such as the one in Novi, are helping OEMs meet their engineering requirements down to the last detail – something quite unimaginable in a previous era. The GEC model is finding favor with OEMs since it brings them triple benefits: operational flexibility, reduced cost, access to emerging markets, and, importantly, innovation on the product engineering front. With GECs, backed by collaborative design and development software and high-speed fiber-optic cables, getting into full throttle, product engineering becomes a global play. Speeding this shift to globalized engineering is a shortage of key technical and engineering skills as well as a general weakening of developed markets.

The logic underlying a GEC is that, under the impact of globalization, businesses are dispersing their production and distribution chain across the world. Increasingly, manufacturing OEMs are deciding in favor of globally dispersed production based on considerations like lowered cost, reduced idea-to-finished product cycle, and nearness to customers and suppliers. Access to skilled workforces, as well as attractive tax and cash incentives by local governments, is also tempting for manufacturers. More importantly, the GEC approach balances workload efficiently across global engineering teams. Because they provide OEMs with ready access to highly-skilled talent, be it on-site, near-site, or in an offshore location.

The GEC model also gives manufacturers the flexibility to ramp-up and ramp-down resources based on need. For example, project heads at an OEM reckon they need 15 people in the first three months of a project to manage the initial workload at a budgeted cost , and at the end of three months, they feel they require 4 more employees, for a stipulated period only, to cope with increased workload , traditionally this could have been done by hiring 4 employees onsite at a very high cost and that would have 2-3 months however in the GEC model , the ramp up happens seamlessly at GEC by temporary allocation from the large engineering talent pool of the trained workforce . When that timeframe has passed, the team can revert to its original size. It can again be ramped up, but if and only if a requirement arises. This way businesses are also able to sweat their assets, squeeze them to the dregs, and extract the most value. The technology infrastructure (CAD, PLM licenses), for instance, can be used 24/7 across engineering teams, no matter what time zone or city the engineers are located in: Coventry, Bengaluru, Bangkok, Los Angeles, Mexico City, Singapore, or Stuttgart. In turn, this ensures true value out of the investment in technology infrastructure (hardware / licenses) as well as cost benefits. The thing to note here is that the beyond the core team, the client is charged only for the time and resources spent on the engagement (under a “Time & Resources model”).

Both engineering services and IT services are based on the global delivery model in which work is moved to teams in globally dispersed centers capable of executing it in a faster and cost-friendly manner. As the sun sets on one global delivery center, another one somewhere in this world picks up the baton and settles down to work. All of them are fitted out with state-of-the-art telecom networks and tools for real-time communication. But that’s where the similarity between globalized engineering services and IT services ends. A programmer in IT services can deliver clean lines of code before the client’s deadline and be done with it. Engineering services represent a different kettle of fish. The data file involved is typically huge, so it’s not easy to share or transfer it as is. This means engineers in a GEC must leverage lots of Intellectual property tools, like an algorithm that breaks down a large file shared by the client that sets the GEC workflow in motion. Next, the team processes the file using CAE packages and finally, the processed file is rebuilt into its original form (again using proprietary tools) and only after this can it be shared with the client. Also, additional tools for project and program management are leveraged to give customers live access to all project related data and matrices like first time right, defect density, milestone progress, etc. These matrices are captured behind the scenes in a seamless and automated way so there is no real need to create reports or dashboards and send them as emails but just access them in central system that acts as a single point of truth, accessed by global engineering teams, project managers for project monitoring, reviews and contract management.

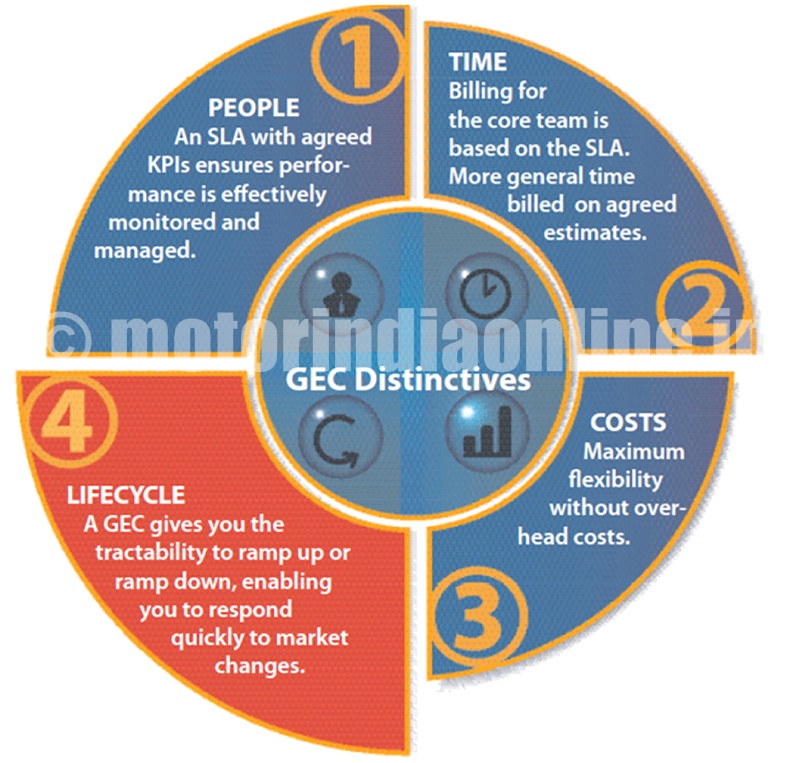

Essentially, a GEC wraps around the following pillars to ensure continuous availability and uptime for clients while making the wheels of product development go faster:

PEOPLE: The resources in a GEC assigned to a task know what’s expected of them and how best they can achieve it. The comparative performance of each individual and team, in relation to industry bests, is captured in the form of service-level agreements (SLAs) and key performance indicators (KPIs).

TIME: The SLA, which is the contracted delivery time of service and performance, serves as the baseline for billing. Any general time, outside of this, is billed as per agreed rates.

COSTS: Clients are increasingly uneasy with the age-old approach in costing (e.g., the time-and-material model in which billing is based on the hours and materials that go into a project). Results-based billing ($ per design) is coming into vogue and GECs have been quick to pick up on this trend. Besides, steps are also in place to ensure customers are adequately compensated in the event of a missed SLAs and deliverables – however highly unlikely this might be.

LIFECYCLE: GECs can rapidly add resources to cope with ‘punishing’ workloads across the production lifecycle as well as scale down equally fast when the load is relatively low. Which means clients have access to engineers when and where they need them and pay only for the services they consume, nothing more. Also over period, a maturity roadmap can be developed to do more complex work at GEC supported by a methodical competency development plan.

In effect, a GEC functions as the extended engineering design arm of a manufacturer, helping it overcome skills shortage in hardcore engineering disciplines, and this is particularly acute in developed markets. In addition, it frees up the bandwidth of in-house design engineers, so they can focus on core activities. More than ever before, OEMs across manufacturing verticals are banking on technology prowess of GECs to bring better engineered and designed products to market faster. They also make use of global teams as engineering partners in areas like component repair and ongoing maintenance. The results are also encouraging: more satisfied customers, effective and faster delivery, as well as noticeable cost reduction. And considering that a GEC enjoys proximity to customers in a fast-expanding economy and skilled people steeped in the realities of the local market, it can indeed serve as a powerful conduit to opportunity for manufacturers – now and in the future.

By Anand Bhade, President of Asia Pacific Sales, Tata Technologies