The technology enables heavy-duty trucks to operate on bio-methane (renewable natural gas) and natural gas with the same power, torque, efficiency and performance as diesel engines, and with even better results running on hydrogen

Westport Fuel Systems Inc. (WFS), a global leader in alternative fuel, low-emissions transportation technologies, recently revealed their H2 HPDI fuel system in a demonstrator truck. WFS’ HPDI™ fuel system technology enables heavy-duty trucks to operate on bio-methane (renewable natural gas) and natural gas with the same power, torque, efficiency and performance as diesel engines, and with even better results running on hydrogen, all while meeting global emissions regulations. The H2 HPDI fuel system was used in a fully functional demonstrator vehicle to show the ease with which a commercially available, production LNG HPDI system can operate on a zero-carbon fuel like green hydrogen.

The H2 HPDI fuel system offers a cost-effective solution with a zero carbon solution that delivers, tank to tailpipe, up to 98% CO2 reduction over diesel, and allows manufacturers to leverage their investment in vehicle drivetrain design, supply chain and manufacturing by continuing to plan around low carbon hydrogen internal combustion engines. The H2 HPDI demonstrator truck was on display at the 2022 ACT Expo held at Long Beach, California from May 9-12, 2022. Some of the H2 HPDI engine specifications include 20% higher power and torque than the base diesel engine efficiency, 5-10% better thermal efficiency than the base diesel engine turbocharged 13 litre in-line six-cylinder engine. It operates with hydrogen through pilot ignition and has a four-cycle, compression ignition and direct injection.

“We believe H2 HPDI is compelling with near-zero greenhouse gas emissions at a lower cost than fuel cell vehicles or battery electric vehicles, particularly for heavy-duty, long-haul trucking,” said David Johnson, CEO, Westport Fuel Systems. “We have developed the engine to utilise the capability of HPDI to deliver what is needed today in the marketplace, using hydrogen in place of natural gas, with development work happening at Westport Fuel Systems facilities, and through previously announced programs with AVL, TUPY and Scania. And we expect new H2 HPDI programs with other partners to come soon.”

The Technology

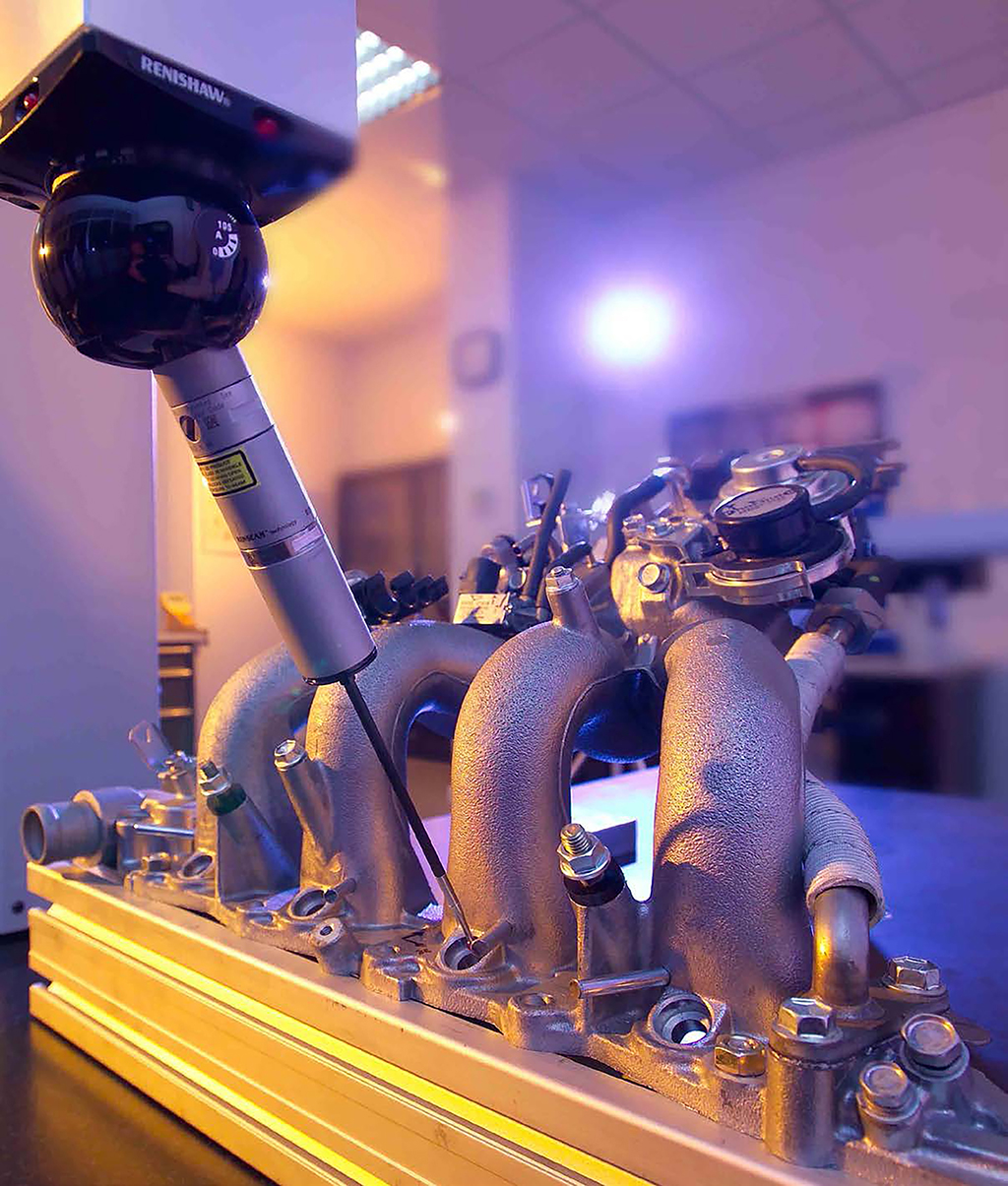

The HPDI fuel system technology uses compression ignition combustion with the overwhelming majority of the energy derived from the combustion of, typically, a gaseous fuel. Combustion is initiated via late cycle direct injection of a small quantity of pilot fuel, followed by direct injection of the primary gaseous fuel – both fuels are injected via a proprietary dual concentric needle injector design. By utilising diesel-cycle thermodynamics, the HPDI fuel system retains the thermal efficiency, power, torque and engine braking of the base diesel internal combustion engine.

“HPDI has long been established as matching diesel engine performance and efficiency, and now we have demonstrated power, torque and efficiency exceeding that of the diesel base engine by migrating from natural gas HPDI to H2 HPDI,” said Scott Baker, Vice President (Engineering), Westport Fuel Systems. “The advantage of HPDI combustion is that it retains the high compression ratio of the base diesel engine and does not suffer from engine knocking as the H2 is injected towards the end of the compression stroke just as pilot ignition and combustion begins.” The HPDI fuel system technology has seen growth in global markets as OEMs and operators are looking for ways to meet environmental regulations without sacrificing their power density and range.

There are thousands of HPDI trucks on the road today and the growth of HPDI sales in Europe has averaged over 100% per year over the last three years while other markets around the globe are taking notice as well. Moreover, many of these European trucks are running on significant blends of biogas or renewable natural gas. This represents a deep reduction in carbon emissions as a result of the commercial maturity and availability of the HPDI technology today. “Hydrogen is a promising next step for carbon neutral heavy-duty transportation applications as a hydrogen-fuelled internal combustion engine enables carbon neutral transportation utilising existing base engine technology, like our proven LNG HPDI fuel system technology,” said Anders Johansson, Vice President (Heavy-Duty OEM), Westport Fuel Systems.

“With the H2 HPDI fuel system we have the opportunity to make a significant positive impact on the global transportation market,” he added. Westport Fuel Systems is driving innovation to power a cleaner tomorrow. The company is a leading supplier of advanced fuel delivery components and systems for clean, low-carbon fuels such as natural gas, renewable natural gas, propane and hydrogen to the global automotive industry. Its technology delivers the performance and fuel efficiency required by transportation applications and the environmental benefits that address climate change and urban air quality challenges. It is headquartered in Vancouver, Canada, with operations in Europe, Asia, North America and South America.