The Indian population is now almost 1.21 billion, 181 million more than just 10 years ago. India is growing fast and is offering huge scope for construction activities in different fields. With rising demand for backhoes, wheeled loaders, Soil Compactor and concrete mixers, construction works in the country now account for almost 50 per cent of the overall annual capital invested. This in fact amounted to seven to eight per cent of GDP or $1.53 trillion in 2010, and this financial commitment continues unabated. The heavy investments made are for roads and highways, ports & airports, irrigation projects, as well as railways, telecommunications, energy supply and urban infrastructure.

The much-needed infrastructure projects imply that India will be one giant construction site for many years to come. This is not only good news for manufacturers of construction machinery but has helped boost demand for driveline technology and axle systems from ZF.

ZF has been represented in India with joint ventures and license partnerships for over three decades. In 2007, ZF India Private Ltd. commenced operations in Pune. The focus of production is on axles and off-road driveline and commercial vehicle technology. The upswing in the construction machinery sector is also apparent in ZF’s performance on site: the assembly plant comprises factory buildings with a surface area of 2,500 sq. m. (approx. 27,000 sq. ft.) plus a 1,500 sq.-m (approx. 16,000 sq. ft.) warehouse and an integrated aftermarket service facility.

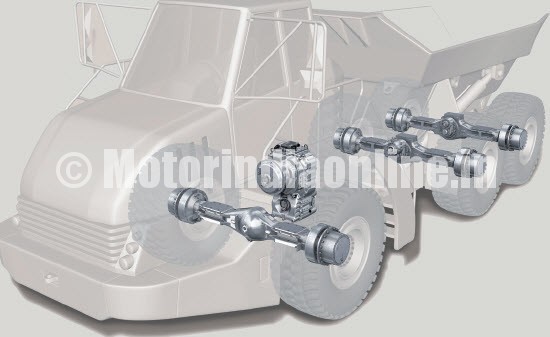

ZF’s off-highway division started its localization program through assembly of backhoe axles in 2010, following up in quick successions with localization of power shift backhoe transmissions and loader axles to key construction equipment manufacturers including JCB India, Tata Hitachi, Leyland Deere and Leeboy. Together with its clients, ZF India assumes responsibility right from the project phase as system provider for planning, product development, quality control and logistics and, finally, mass production.

Over several years, ZF has supplied around significant number of transmissions and axles in the construction equipment segment in India. Of-late two-third of these sets was delivered from its Pune facility while the rest was sourced from its facilities in Germany and the US.

In addition to expanding to a new location, ZF is also working on reinforcing its sales team. The company is looking to leverage on German product quality by expanding its workforce with a more technical approach. It is also working on training its Indian team to match world-class standards when it comes to designing, developing and marketing top-notch products in the domestic market.

Moving forward, ZF plans to use India as a hub for its international operations and supply products to global markets as well. “We see India as a best-cost country to support our global customer base. In our five-year plan, we are targeting 50% domestic sales and 50% exports. We will use India as a hub for special products like backhoe loader components for supply to the South-East Asian market, and also to Europe and may be even to America”, says Mr. Hermann Beck, Executive Vice President Industrial Technology, Head Off-Highway Systems, ZF.

From a global perspective, India as well as China and Russia are top priority for ZF. “Considering our investments and activities in the Indian market, it is certainly within the top three priority markets for ZF. China is a very important market for us, and so is Russia. Though our investments in Russia are not as large as in India, it is a high potential market like India”, adds Mr. Beck.

Latest innovations

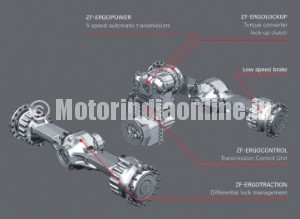

With cost reduction, lowered fuel consumption and increased productivity being the key parameters under focus in the construction equipment industry, ZF caters to the needs of its customers with a range of innovative products, including the ZF-ECOMIX II, ZF ERGOPOWER and ZF AS Tronic mid.

ZF engineers have been constantly looking for further improvement potentials and challenges and with the new ZF-ECOMIX II generation, significant improvements have been achieved. ZF ECOMIX II is smaller and lighter but tougher, and produces less noise in operation.

The ZF ERGOPOWER is a tried and tested transmission system which has been optimized for different construction machinery types. It offers an innovative feature of five gears instead of four. Therefore, the noise-optimized transmission allows more comfortable and easier handling, high shifting quality and flexibility. Moreover, the operating costs can be further reduced. The ZF ERGOPOWER provides additional possibilities for connecting an electronic driveline management, thus enabling vehicle-specific controls.

ZF technology is used in almost all vehicles which operate in construction sites. For instance, the manual Ecosplit transmissions move heavy trucks such as tippers or mixers. These applications benefit from a transmission which excels through its high service life and the particular feature of being maintenance-free. Construction machines equipped with automatic transmissions of the ZF-AS Tronic range are even more comfortable and efficient, with the added advantages of reduced fuel consumption and less wear, combined with enhanced operating comfort. For applications requiring particularly high torques – like mobile cranes – TC Tronic with torque converter provides forward motion accurate to the millimeter.